Zigong Xingyu Cemented Carbide Dies & Tools Co., Ltd. |

|

Customized Long Life Hard Wearing Tungsten Carbide PDC Drill Bit Nozzle

For nozzles, tungsten Carbide nozzle is the most rugged and durable and provides the best value.

A nozzle is a device designed to control the direction or characteristics of a flow (especially to increase velocity) as it exits (or enters) an enclosed chamber or pipe via an orifice. For nozzles, tungsten Carbide nozzle is the most rugged and durable and provides the best value.

Tungsten carbide nozzle is made by the precision machining with the tungsten carbide materials (superhard alloy). The hardness reached over HRA90 degree while the anti-bending degree reached over 2300N/mm2. On machining tungsten carbide nozzle, we do the precision grinding and surface treatment to achieve Ra0.1 of the bore roughness and the Ra0.025 of the R place of both ends. There is a scientific curvature radius design in the both entrance. This design can ensure a smooth transit of the thread. Due to the overall materials processing, and no elevation in the bore, the phenomenon of easy-bending and plugging has been improved comparing with the ruby nozzle.

Tungsten carbide nozzle is made from hot pressing with straight bore and venturi bore type. Due to its hardness, low density and excellent wear and anti-corrosion, Tungsten carbide nozzle has been widely used in sandblasting and shot peening equipment, offering a long life with optimum air and abrasive use.

Factory supply tungsten carbide oil drill bit nozzle

Cemented carbide nozzle also known as the tungsten carbide nozzle, is mainly used in chemical industry, food, machinery, metallurgy, architecture and other industries for pulverizing, derusting, cleaning, atomization, etc. The hard alloy nozzles produced by our company have a variety of specifications, processed and made with high quality raw material. It has the characteristics of high temperature resistance, corrosion resistance, abrasion resistance, high precision and so on.

Product Description

Our tungsten carbide waterjet nozzles inner tube is high finish blast hole, and the use of our unique polishing technology pores to keep the hardness of inside waterjet nozzles is same as the outside of water jet nozzles. Comparing to other common tungsten water jet nozzles:higher hardness, higher density, higher wear resistance, higher stability.Consistent and long service life.

Material: 100% tungsten carbide

Density: 15.7g/cm

Rockwell hardness: 96HRA

Size: cutomized

Grade List

| Grade | ISO Code | Chemical Composition(%) | Physical Mechanical Properties (≥) | Application | ||||

| WC | Co | Density g/cm3 | Hardness(HRA) | T.R.S N/mm2 | ||||

| YG3 | K01 | 97 | 3 | 14.90 | 91.00 | 1180 | Suitable for finishing of cast iron,non-ferrous metals,alloys and non-metallic materials,and semi-finishing vehicles for intermittent cutting. | |

| YG6 | K10 | 94 | 6 | 15.10 | 92.00 | 1420 | Finishing of chilled hard alloy cast iron and heat resistant alloy steel and ordinary cast iron. | |

| YG6X | K20 | 94 | 6 | 15.10 | 91.00 | 1600 | Cast iron, non-ferrous metals and alloys, non-metallic materials, medium to cutting, semi-finishing and finishing. | |

| YG8 | K20-K30 | 92 | 8 | 14.90 | 90.00 | 1600 | Suitable for casting of cast iron, non-ferrous metals and their alloys and non-metallic materials, roughing of sections and rough cutting. | |

| YG10 | K40 | 90 | 10 | 14.70 | 89.00 | 1900 | Suitable for the production of drawing dies, wear parts and stamping parts and cores for hard alloy automatic presses. | |

| YG10X | K40 | 89 | 10 | 14.70 | 89.50 | 2200 | Suitable for small diameter micro drills, end mills, rotary boring tools, etc. | |

| YG15 | K30 | 85 | 15 | 14.70 | 87.00 | 2100 | Forging, perforating and stamping tools for steel bars and steel tubes with high compression ratios and working under large stresses. | |

| YG20 | K30 | 80 | 20 | 13.70 | 85.50 | 2500 | Stamping die, stamping watch parts, musical instrument spring piece. | |

| YG20C | K40 | 80 | 20 | 13.70 | 82.00 | 2200 | punching battery case, toothpaste skin mold, small size steel ball, screw, nut stamping die, hot rolling twist drill bit plate. | |

| YG30 | G60 | 70 | 30 | 12.80 | 82.00 | 2750 | Production of standard parts, bearings, tools and other industries for cold heading, cold punching, cold pressing die. | |

Details Of Tumgsten Carbide Nozzle

| Type | Dimension (mm) | ||||||||

| φA ±0.25 | φB ±0.25 | φC ±0.25 | φD ±0.20 | φE ±0.20 | F ±1 | G ±1 | M ±1 | K ±0.5 | |

| XP01-1 | 24.5 | 30.0 | 5.0 | 9.0 | 18.0 | 50.0 | 69.0 | 21.0 | 130.0 |

| XP01-2 | 24.5 | 30.0 | 8.0 | 12.5 | 20.0 | 50.0 | 69.0 | 21.0 | 140.0 |

| XP01-3 | 24.5 | 30.0 | 10.0 | 13.5 | 21.0 | 50.0 | 69.0 | 21.0 | 170.0 |

| XP01-4 | 24.5 | 30.0 | 13.0 | 19.5 | 27.0 | 50.0 | 69.0 | 21.0 | 226.0 |

| XP01-5 | 30.0 | 36.0 | 6.5 | 12.5 | 19.5 | 54.0 | 70.0 | 20.0 | 130.4 |

| XP01-6 | 30.0 | 36.0 | 8.0 | 12.5 | 12.5 | 54.0 | 70.0 | 20.0 | 141.0 |

| XP01-7 | 30.0 | 36.0 | 11.0 | 15.0 | 12.5 | 55.0 | 69.0 | 21.0 | 200.0 |

| Type | Dimension (mm) | ||||||

| φA ±0.25 | φB ±0.25 | φC ±0.20 | φD ±0.20 | φE ±0.25 | F ±2 | K ±0.5 | |

| XP02-1 | 32.0 | 25.0 | 6.2 | 8.0 | 16.0 | 45.0 | 78.0 |

| XP02-2 | 32.0 | 25.0 | 8.0 | 10.0 | 18.0 | 45.0 | 78.0 |

| XP02-3 | 32.0 | 25.0 | 11.0 | 13.0 | 21.0 | 45.0 | 78.0 |

| XP02-4 | 38.0 | 32.0 | 6.2 | 6.2 | 16.0 | 45.0 | 80.0 |

| XP02-5 | 38.0 | 32.0 | 8.0 | 8.0 | 18.0 | 45.0 | 80.0 |

| Type | Dimension (mm) | |||||

| φA ±0.15 | φB ±0.15 | φC ±0.15 | φD ±0.15 | φE ±0.20 | K ±0.20 | |

| XP03-1 | 18.0 | 27.0 | 6.0 | 12.0 | 36.0 | 72.0 |

| XP03-2 | 18.0 | 27.0 | 8.0 | 14.0 | 36.0 | 72.0 |

| XP03-3 | 18.0 | 22.0 | 6.0 | 13.0 | 36.0 | 86.0 |

| XP03-4 | 18.0 | 22.0 | 8.0 | 15.0 | 36.0 | 86.0 |

| Type | Dimension (mm) | ||||||||||

| φA ±0.3 | φB ±0.2 | φC ±0.2 | φD ±0.3 | F ±0.3 | F | G | H | I | M ±1 | K ±0.5 | |

| XP04-1 | 20.0 | 26.0 | 6.0 | 9.0 | 15.0 | 24.0 | 3.0 | 15.0 | 21.0 | 9.0 | 110.0 |

| XP04-2 | 20.0 | 26.0 | 8.0 | 11.0 | 17.0 | 24.0 | 3.0 | 15.0 | 21.0 | 9.0 | 110.0 |

| XP04-3 | 25.5 | 33.0 | 10.0 | 13.0 | 19.0 | 44.0 | 3.0 | 10.0 | 29.0 | 21.0 | 110.0 |

| XP04-4 | 25.5 | 33.0 | 11.0 | 14.0 | 20.0 | 44.0 | 3.0 | 10.0 | 29.0 | 21.0 | 110.0 |

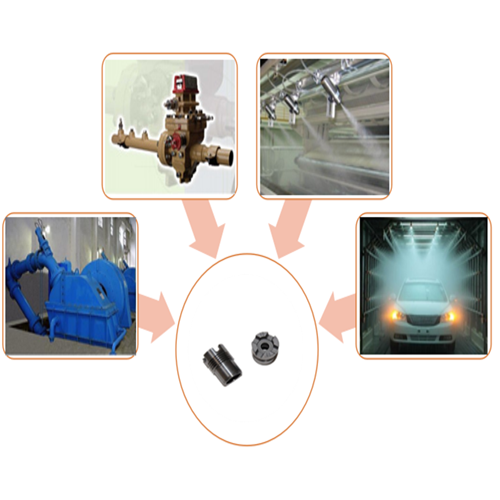

Product Application Scene

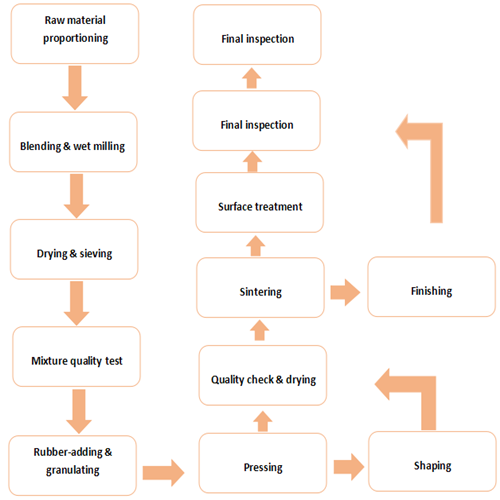

Production Process

FAQ

Q1: Why choose us?

A1: We’ve been in this industry since 1999, we have a professional working team and cutting-edge technology, and our products have been well received on American and European market.

Q2: What’s your MOQ?

A2: It depends on the products, for drill bit nozzle, the MOQ is 50 pieces.

Q3: Do you provide sample?

A3: Yes, we provide free sample for our customer, but the freight shall be covered by the buyer.

Q4: Can I place mixed orders?

A4: Yes, mixed orders is accepted.

Q5: What’s you deliver time?

A5: Within 7 days after payment.