Zigong Xingyu Cemented Carbide Dies & Tools Co., Ltd. |

|

Customized Factory Manufacturing High Pressure Wear Resistance

Spray Tungsten Carbide Nozzle

Application

Tungsten carbide spray nozzle has good wear resistance, long life,

is the key determinant of coating efficiency and coating quality.

When the paint, the paint atomization, flow, spray rate by the

geometry of the nozzle, with the pore size determined by the

accuracy of machining. Select the nozzle and its technical

parameters has become the key painting is one of the coating

efficiency and coating quality assurance of the most effective

means.

The most widely used standard nozzle, the nozzle opening was olive,

oval spray pattern, many models of this nozzle, the spray pattern

width of 150mm to 600mm, the paint discharge amount (0.2 ~ 5.0) L /

min, even up to 10L / min or more, to meet the needs of a variety

of spray, which is called the equivalent diameter of the nozzle

diameter, the so-called equivalent diameter refers to the opening

of the nozzle diameter was olive, equivalent to the same amount of

spray paint circular opening of the nozzle diameter.

tungsten carbide nozzles are usually used to sandblasting,

therefore, users also call them tungsten carbide sandblasting

nozzles. The hardness reached over HRA90 degree while the

anti-bending degree reached over 2300N/mm. On machining tungsten

carbide spray nozzle, we do the precision grinding and surface

treatment to achieve Ra0.1 of the bore roughness and the Ra0.025 of

the R place of both ends. There is a scientific curvature radius

design in the both entrance. This design can ensure a smooth

transit of the thread. Due to the overall materials processing, and

no elevation in the bore, the phenomenon of easy-bending and

plugging has been improved comparing with the ruby nozzle.

Grade List

Cobalt Binder Grades | ||||

| ||||

Grade | Binder(wt%) | Density(g/cm3) | Hardness(HRA) | TRS(≥N/mm2) |

YG3 | 3 | 15.30 | 91.00 | 1180 |

YG6 | 6 | 15.10 | 92.00 | 1420 |

YG6X | 6 | 15.10 | 91.00 | 1600 |

YG8 | 8 | 14.90 | 90.00 | 1600 |

YG10 | 10 | 14.70 | 89.00 | 1900 |

YG10X | 10 | 14.70 | 89.50 | 2200 |

YG15 | 15 | 14.20 | 87.00 | 2100 |

YG20 | 20 | 13.70 | 85.50 | 2500 |

YG20C | 20 | 13.70 | 82.00 | 2200 |

YG30 | 30 | 12.80 | 82.00 | 2750 |

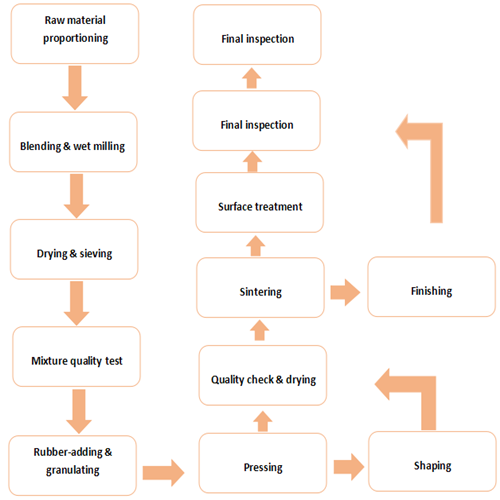

Production Process

FAQ

Q1: Are you trading company or manufacturer ?

A1: We are Factory with 20 years of production experience.

Q2: Where is your factory?

A2: We are located in Zigong city, Sichuan province where is 3

hours away from Chengdu by Car.

Q3: Is the competitive price of tungsten carbide nozzle?

A3: We have our own Factory. Due to strong production and

distribution system, we promise to offer our customers the most

competitive price.

Q4: Is the top quality?

A4: Yes. All products will be tested before bulk processing, and we

will check the physi-cal properties, shape and

tolerance for ensuring qualified products before shipping.

Q5: What’s your delivery time ?

A5: For the normal type which we have mold it takes 10-15 days

after receiving the advance payment.

For the non standard which we do not have mold it takes 15-25 days

after receiving the advance payment.

Q6: Do you provide samples ? is it free or extra ?

A6: Yes, we could offer the sample (less than 1Kg) for free charge

without freight charge.