Zigong Xingyu Cemented Carbide Dies & Tools Co., Ltd. |

|

Mechanical Seal Carbide Insert API11AX Stellite Valve Seat

Grade List

| Grade | WC% | CO% | Hardness (HRA) | Desnity (G/M³) | T.R.S (Mpa) | Metallographic analysis | Application |

| YG6 | 94% | 6% | 91 | 14.6-15.0 | 1700 | A02B02C02 | Widely used in all kinds of hardware industry, valve, bearing, die casting , punching, grinding measurement. |

| YG6X | 94% | 6% | 92 | 14.6-15.0 | 1450 | A02B02C02 | Widely used in all kinds of hardware industry, valve, bearing, die casting , punching, grinding measurement. |

| YG8 | 92% | 8% | 89 | 14.4-14.8 | 1800 | A02B02C02 | Widely used in valves,bearing, die casting , punching, grinding

measurement,hardness tester, petroleum, chemical industry,

aeronautics and astronautics. |

Grade and applicaton for valve seat

| Grade | Co (wt%) | Density (g/cm³) | Hardness(HRA) | TRS (≥N/mm²) | Application |

| XC100 | 5.8-6.2 | 14.6-15.0 | 91.5-92.5 | 2000 | Wear-resistant |

| XC101 | 5.8-6.2 | 14.6-15.0 | 91.5-92.5 | 2500 | |

| XC200 | 7.8-8.2 | 14.5-14.9 | 91.0-92.0 | 2100 | |

| XC201 | 7.8-8.2 | 13.5-14.9 | 91.0-92.0 | 2800 | |

| XC300 | 9.8-10.3 | 14.2-14.6 | 90.5-91.5 | 2600 | |

| XC301 | 9.8-10.3 | 14.2-14.6 | 90.5-91.5 | 3200 | |

| Grade | Ni (wt%) | Density (g/cm³) | Hardness (HRA) | TRS (≥N/mm²) | Application |

| XN100 | 6.5-7.5 | 14.5-14.8 | 88.5-91.0 | 1800 | Corrosion-resistant |

| XN101 | 6.5-7.5 | 14.5-14.8 | 88.5-91.0 | 2200 | |

| XN300 | 10.0-11.0 | 14.2-14.6 | 86.5-89.5 | 2100 | |

| XN301 | 10.0-11.0 | 14.2-14.6 | 86.5-89.5 | 2400 |

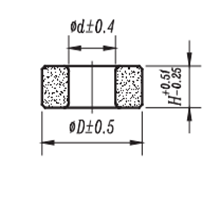

| Seats dimension (mm) | ||

| D | d | H |

| 19.48 | 11.68 | 12.7 |

| 22.66 | 13.97 | 12.7 |

| 28.22 | 17.02 | 12.7 |

| 33.81 | 20.96 | 12.7 |

| 36.09 | 24.38 | 12.7 |

| 41.43 | 26.92 | 12.7 |

| 48.79 | 33.27 | 12.7 |

| 74.93 | 43.18 | 19.05 |

| Ball dimension (mm) | ||

| D±1.27(mm) | ||

| 15.88 | ||

| 19.05 | ||

| 23.83 | ||

| 28.58 | ||

| 31.75 | ||

| 34.93 | ||

| 42.88 | ||

| 57.15 |

Specifications of Valve Ball & Valve Seat for API Sucker Rod Pump

Model/Item | V11-106 | V11-125 | V11-150 | V11-175 | V11-200 | V11-225 | V11-250 | V11-375 |

| Ball-D +0.020/-0.010 (+0.51/-0.25) | 15.88 (0.625in) | 19.05 (0.75in) | 23.83 (0.938in) | 28.58 (1.125in) | 31.75 (1.25in) | 34.93 (1.375in) | 42.88 (1.688in) | 57.15 (2.25in) |

| Seat-ID ± 0.050 (± 1.27) | 11.68 (0.46in) | 13.97 (0.55in) | 17.02 (0.67in) | 20.96 (0.825in) | 24.38 (0.96in) | 26.92 (1.06in) | 33.27 (1.31in) | 43.18 (1.7in) |

| Seat-OD +0.000/-0.005 (+0.00/-0.13) | 20.14 (0.793in) | 23.32 (0.918in) | 29.67 (1.168in) | 35.26 (1.388in) | 37.54 (1.478in) | 43.69 (1.72in) | 51.05 (2.01in) | 78.03 (3.072in) |

| Seat-H +0.020/-0.010 (+0.51/-0.25) | 12.70 (0.500in) | 12.70 (0.500in) | 12.70 (0.500in) | 12.70 (0.500in) | 12.70 (0.500in) | 12.70 (0.500in) | 12.70 (0.500in) | 19.05 (0.750in) |

| 10600 | 12500 | 15000 | 17500 | 20000 | 22500 | 25000 | 37500 | ||

| D (customized) | Inch | 0.625 | 0.725 | 0.938 | 1.125 | 1.250 | 1.375 | 1.688 | 2.250 |

| mm | 15.88 | 19.05 | 23.83 | 28.58 | 31.75 | 34.93 | 42.88 | 57.15 | |

| H -0.020/-0.010 (+0.51/0.25) | Inch | 0.500 | 0.500 | 0.500 | 0.500 | 0.500 | 0.500 | 0.500 | 0.750 |

| mm | 12.70 | 12.70 | 12.70 | 12.70 | 12.70 | 12.70 | 12.70 | 19.05 | |

| FZ +0.000/-0.031 (+0.00/-0.78) | Inch | 0.767 | 0.892 | 1.11 | 1.331 | 1.421 | 1.631 | 1.921 | 2.950 |

| mm | 19.48 | 22.66 | 28.22 | 33.81 | 36.09 | 41.43 | 48.79 | 74.93 | |

| OD +0.000/-0.005 (-0.00/-0.13) | Inch | 0.793 | 0.918 | 1.168 | 1.388 | 1.478 | 1.720 | 2.010 | 3.072 |

| mm | 20.14 | 23.32 | 29.67 | 35.26 | 37.54 | 43.69 | 51.05 | 78.03 | |

| ID +/-0.050 (+/-1.27) | Inch | 0.460 | 0.550 | 0.670 | 0.825 | 0.960 | 1.060 | 1.310 | 1.700/1.800 |

| mm | 11.68 | 13.97 | 17.02 | 20.96 | 24.38 | 26.92 | 33.27 | 43.18/47.75 | |

Dimensional Symbol | V11-106 | V11-125 | V11-150 | V11-175 | V11-200 | V11-225 | V11-250 | V11-375 |

Ball-D +0.020/-0.010 (+0.51/-0.25) | 15.88 (0.625in) | 19.05 (0.75in) | 23.83 (0.938in) | 28.58 (1.125in) | 31.75 (1.25in) | 34.93 (1.375in) | 42.88 (1.688in) | 57.15 (2.25in) |

Seat-ID ± 0.050 ( ± 1.27) | 11.68 (0.46in) | 13.97 (0.55in) | 17.02 (0.67in) | 20.96 (0.825in) | 24.38 (0.96in) | 26.92 (1.06in) | 33.27 (1.31in) | 43.18 (1.7in) |

Seat-OD +0.000/-0.005 +0.00/-0.13 | 20.14 (0.793in) | 23.32 (0.918in) | 29.67 (1.168in) | 35.26 (1.388in) | 37.54 (1.478in) | 43.69 (1.72in) | 51.05 (2.01in) | 78.03 (3.072in) |

Seat-H +0.020/-0.010 (+0.51/-0.25) | 0.500 (12.70in) | 0.500 (12.70in) | 0.500 (12.70in) | 0.500 (12.70in) | 0.500 (12.70in) | 0.500 (12.70in) | 0.500 (12.70in) | 0.750 (19.05in) |

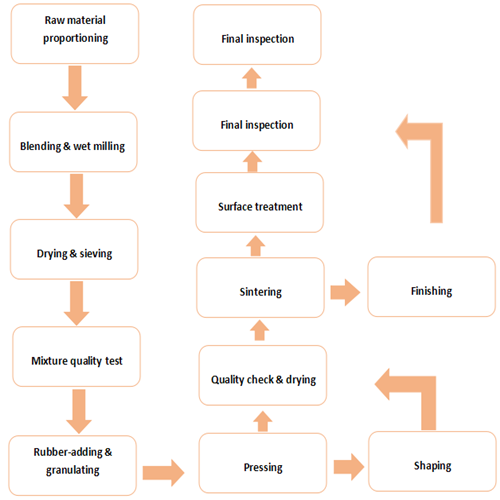

Production Process

FAQ

Q1: Are you the real reliable factory or just a trader company?

A1: We are the REAL factory located in Zigong ,China, we currently have over than 80 employees.

Q2: There have many companies called they are 'factory', how can I identified the truth?

A2: tips1, Familiar with the processing equipment which are for produce to your required products, and visit their company as well as their processing equipment.

tips-2, Appoint one of your reliable friend who is in China to visit their factory.

tips-3, Check their Certs and proof of its authenticity, instead to only check the PS version superficially.

tips-4, Searching on the Satellite maps to check their location.

tips 5, In fact, almost every company can apply for the Certs, but, only the factory can get the patents (such as: invention patent, utility patent or design patent) for their product, and a small factory or a trading company havn't the R&D support to apply patents.

tip-6, Factory are always available to take the photos at any time during the production process.

Q3: Can you give warranty of your products?

A3: Yes, we 100% satisfaction guarantee on all items. we have the independent inspection Dep.with the complete advanced product quality instrumentation to carry out IQC, PQC & FOC, the detailed inspection pictures and report will be sent to you for confirmation before delivery.

In case there have quality problem, just pls kindly to provide the pictures to show the problem by email,

we will 100% responsible for our problems and to provide the replacements to you at our costs.

Q4: Can we get support if we have our own market position?

A4: Please inform us your detailed mind on your market demand, we will discuss and propose helpful suggestion for you, to find the best solution for you.