Zigong Xingyu Cemented Carbide Dies & Tools Co., Ltd. |

|

Customized Bearing Sintered Tungsten cemented Carbide Cutting Tools Wear Parts

Application

Tungsten is mixed with carbon to make a very strong, very resistant material called tungsten carbide. Tungsten carbide is the hardest of all metals. It is about 10 times harder than 18K gold, 5 times harder than tool steel, and 4 times harder than titanium. So it is suit for making cutting tools and wear-resistant tools for metalworking, drilling for oil and gas, mining, and construction. It is ideally suited for wear parts, other machine parts and dies which are subject to severe service conditions, such as high temperatures, corrosion and abrasion. In recent years, tungsten carbide has emerged as a superior alternative to steel in many industrial applications.

Because of tungsten carbide's special physical properties, it has a very wide of applications, especially for wear parts. Tungsten products can sustain high temperatures, is abrasion and corrosion resistant which makes it highly suited for wear parts, machine parts and dies. Today a very high percentage of tungsten carbide is cemented carbide used for wear parts. The extensive range of products covers from small balls for ball-point pens to big and heavy products, like hot rolls for rolling mills, punches or dies.

The most common binding material for cemented carbide wear parts

and carbide mining tools is cobalt(WC-Co). The grain size of

tungsten carbide hard-metals is usually fine. Ultra-fine grained is

becoming more important in the area of wear parts, carbide tools

for cutting, tools for cast iron, chip less forming, non ferrous

alloys and wood.

We have got ISO9001-2008 quality certificate and top good quality products could be provided to you. Our Company is a leading professional manufacturer in this field for more than 20 years.We produce both standard and non-standard products. Special Drawings/requirements can be accepted good quality, reasonable price and good service are guaranteed.If you have any interest in our products, please kindly send us your enquiry to us.

Grade List

| Grade | ISO Code | Chemical Composition(%) | Physical Mechanical Properties (≥) | Application | ||||

| WC | Co | Density g/cm3 | Hardness(HRA) | T.R.S N/mm2 | ||||

| YG3 | K01 | 97 | 3 | 14.90 | 91.00 | 1180 | Suitable for finishing of cast iron,non-ferrous metals,alloys and non-metallic materials,and semi-finishing vehicles for intermittent cutting. | |

| YG6 | K10 | 94 | 6 | 15.10 | 92.00 | 1420 | Finishing of chilled hard alloy cast iron and heat resistant alloy steel and ordinary cast iron. | |

| YG6X | K20 | 94 | 6 | 15.10 | 91.00 | 1600 | Cast iron, non-ferrous metals and alloys, non-metallic materials, medium to cutting, semi-finishing and finishing. | |

| YG8 | K20-K30 | 92 | 8 | 14.90 | 90.00 | 1600 | Suitable for casting of cast iron, non-ferrous metals and their alloys and non-metallic materials, roughing of sections and rough cutting. | |

| YG10 | K40 | 90 | 10 | 14.70 | 89.00 | 1900 | Suitable for the production of drawing dies, wear parts and stamping parts and cores for hard alloy automatic presses. | |

| YG10X | K40 | 89 | 10 | 14.70 | 89.50 | 2200 | Suitable for small diameter micro drills, end mills, rotary boring tools, etc. | |

| YG15 | K30 | 85 | 15 | 14.70 | 87.00 | 2100 | Forging, perforating and stamping tools for steel bars and steel tubes with high compression ratios and working under large stresses. | |

| YG20 | K30 | 80 | 20 | 13.70 | 85.50 | 2500 | Stamping die, stamping watch parts, musical instrument spring piece. | |

| YG20C | K40 | 80 | 20 | 13.70 | 82.00 | 2200 | punching battery case, toothpaste skin mold, small size steel ball, screw, nut stamping die, hot rolling twist drill bit plate. | |

| YG30 | G60 | 70 | 30 | 12.80 | 82.00 | 2750 | Production of standard parts, bearings, tools and other industries for cold heading, cold punching, cold pressing die. | |

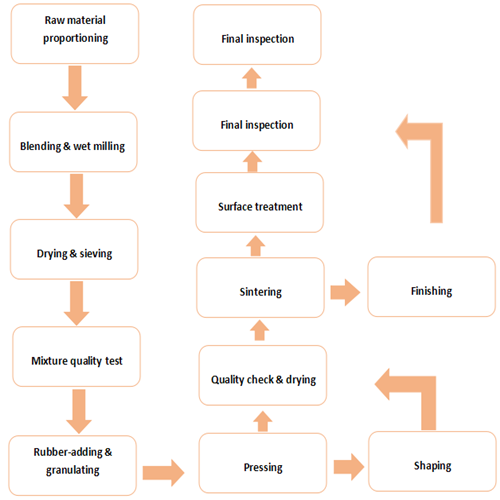

Production Process

FAQ

Q1: How long is your delivery period?

A1: It depends on specific conditions. However, it could be 10 to 15 days on average.

Q2: Do you offer samples?

A2: Yes, we do offer samples. However, buyers need to pay for the freight charge. In addition, whether samples are free or not depends on the quantity you buy.

Q3: How do you pack the products?

A3: In general, we use wood, plastic or carton boxes. We also put some soft materials inside to prevent possible damage on products.

Q4: How much advance payment do I need to make?

A4: If the products you buy are in stock, you need to make full payment; if the products are out of stock, you need to make about 50 percent of full payment and then we will start the production process. However, you still need to pay the rest of charges before we deliver the products.

Q5: What kinds of payment do you accept?

A5: In addition to the patterns of payment shown above, you can discuss with us about in which way you would like to pay.

Please contact us if you have any other questions.