Yixing Champion Industry Ceramic Co., Ltd |

|

Verified Suppliers

|

|

R&D and production of customized thermal insulation products, providing high-quality thermal insulation materials

Product Details

The research and development (R&D) and production of customized thermal insulation products are important aspects of the thermal insulation industry. Here's an overview of how R&D and production processes contribute to the creation of customized thermal insulation solutions:

Customer Needs Assessment: The process begins with understanding the specific requirements and needs of the customer. This includes evaluating factors such as temperature range, insulation performance, durability, size, shape, and any other unique considerations. Close collaboration between the customer and the insulation manufacturer is crucial to ensure a comprehensive understanding of the project requirements.

Research and Development: Once the customer needs are identified, the R&D phase begins. This involves conducting research and exploring various materials, formulations, and manufacturing techniques to develop customized thermal insulation solutions. R&D efforts focus on improving insulation performance, optimizing thermal conductivity, enhancing mechanical strength, and addressing specific challenges associated with the application.

Material Selection: Based on the R&D findings, suitable insulation materials are selected or developed. These materials can include foam plastics, mineral wool, aerogels, ceramic fibers, or other specialized materials. The materials are chosen based on their thermal properties, mechanical strength, chemical resistance, and compatibility with the application.

Prototyping and Testing: Prototypes of the customized thermal insulation products are created to evaluate their performance and suitability for the specific application. Rigorous testing is conducted to validate insulation effectiveness, mechanical durability, chemical resistance, and other relevant parameters. This iterative process helps refine the design and materials to meet the desired performance targets.

Customized Manufacturing: Once the prototype is approved, the customized thermal insulation products enter the production phase. Specialized manufacturing processes, such as injection molding, extrusion, or cutting techniques, are employed to produce the insulation products according to the specific size, shape, and configuration required by the customer.

Quality Control: Quality control measures are implemented throughout the production process to ensure consistent and reliable performance of the customized thermal insulation products. Stringent quality checks are conducted to verify dimensional accuracy, insulation properties, mechanical strength, and adherence to customer specifications.

Installation Support: In addition to the manufacturing process, insulation manufacturers often provide installation support and guidance to ensure the proper integration and utilization of the customized thermal insulation products. This assistance can include on-site training, technical documentation, and troubleshooting assistance to ensure optimal insulation performance.

The R&D and production of customized thermal insulation products require expertise, collaboration, and a deep understanding of the application requirements. By closely working with insulation manufacturers, customers can achieve tailored solutions that meet their specific thermal insulation needs, resulting in improved energy efficiency, temperature control, and overall system performance.

Product Specifications

| Properties | Test Standard | Unit | Value |

| Density 密度 | DIN 53479 | g/cm3 | 1.85 |

| Flexural Strength 抗折强度 at 23°C | ISO 178 | N/mm2 | 400 |

Compressive Strength at 23°C 抗压强度 at 200°C | ISO 604 | N/mm2 | 560 350 |

| Coeff. of Thermal Expansion热膨胀系数 | DIN 53752 | 10-6 K-1 | 15 |

| Thermal Conductivity导热系数 | DIN 52612 | W/mK | 0.23 |

| Continuous Service Temperature 连续使用温度 | - | °C | 250 |

| Maximum Service Temperature最高使用温度 | - | °C | 260 |

| Water Absorption吸水率after24h at 23°C | DIN 53495 | % | 0.1 |

Jiangsu Jingjing Insulation Board Thickness Tolerance Reference

| Insulation board specifications(mm) | Thickness tolerance(mm) |

| 450*400范围内 | ±0.05mm |

| 1000*1000范围内 | ±0.1mm |

| 800*1000范围内 | ±0.01~±0.03mm (Special precision requires grinding with high-precision equipment. Negotiable based on actual dimensions.) |

Feature of product

In addition to efficient thermal insulation properties, Jiangsu Jingjing's mold insulation panels are also designed for high-pressure applications and have excellent mechanical properties. This makes our insulation materials particularly suitable for the need for material stability.

Features

Thermal insulation panels are highly resistant to pressure, especially in higher temperature applications

Efficient thermal insulation

Allows you to control mold temperature more accurately and better improve product quality and production efficiency

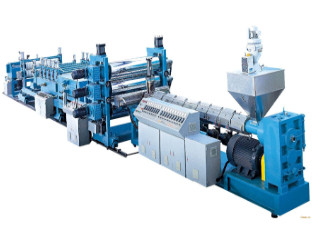

Ensure the stable flow of thermoplastic plastics during processing and forming.

Typical application industries

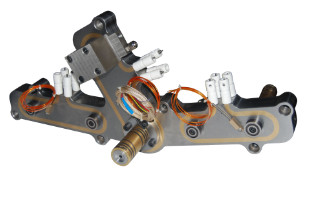

Mold insulation Thermosetting heat press insulation board

Injection molding machine heat insulation board Blow mold insulation board

Hot runner heat insulation board extruder

Jiangsu Jingjing insulation board processing and shipping time reference

Are you still worried about processing heat insulation boards, such as flying dust, affecting equipment accuracy and personnel health?

Are you still worried about product quality problems caused by processing heat insulation boards, such as cracks in holes, out-of-tolerance dimensions, product delamination, etc.

We now provide customer drawing processing services, and the

shipping time is as follows:

| Product processing status | Normal shipping time (working days) | ||||||

| Light sheet products3 working days | |||||||

| Drawing processing products | 5-7days

|

Remark:

The above is the factory shipping time. For the intermediate transportation time, please refer to the transportation time MAP on the website.

*Drawings, please try your best to provide CAD drawings so that our company can speed up the delivery time.

*If the customer is particularly urgent, please use our expedited shipping service. Please refer to the emergency shipping service on the website for details.