Jiangsu Lebron Machinery Technology Co., Ltd. |

|

Blue color High strength smooth straight door frame cold roll forming machine automatic type PLC system control

1. Description of door frame cold roll forming machine

LBM company is producing and offering outstanding quality range of door frame roll forming machines. These door frame roll forming machines can be customized as per customer requirement based. These door frame roll forming machines are mostly known for its stability and superiority. These door frame roll forming machines can be availed at best competitive prices.

LBM company is producing high quality door frame roll forming machines. Most of them are exported to Australia, Thailand, South Africa, Crotia, Sudan, Kuwait, Bangladesh, Turkey, Russia, etc.

2. Technical parameters of door frame roll forming machine

| No. | Item | Description |

| 1 | Suitable Plate Material | Thickness: 1.5-2.0mm, Galvanized steel or blank steel |

| 2 | Working Speed | 12-15 m/min |

| 3 | Roller quantity | 18 rollers |

| 4 | Material of Roller | Gcr15, Quench HRC58-62 Plated Chrome |

| 5 | Material of Shaft | 45# Advanced Steel (Dia: 76mm), thermal refining |

| 6 | Driven system | gear box drive |

| 7 | Main Power with reducer | 7.5KW |

| 8 | Cutting model: | Hydraulic Cutting Cr12mov |

| 9 | Material of Cutting blade | Cr12Mov, Quench HRC58-62 |

| 10 | Hydraulic Station Power | 7.5KW |

| 11 | Operation system | Controlled by industry computer-PLC system. |

| 12 | PLC brand | Siemens with Japan English and Chinese Language |

| 13 | Touch Screen | Siemens Japan |

| 14 | Encoder | Omron, Japan |

| 15 | Electric parts | Schneider |

3. Main components of door frame roll forming machine

| Manual Decoiler | Max Width: 1250mm |

| Inner Diameter: 500mm | |

| Outer Diameter: 1200mm | |

| Max Weight Capacity: 5T | |

| Roll Forming | Raw Material: Colored steel or galvanized steel |

| Material Thickness: 1.5-2mm | |

| Working Speed: 12-15m/min; Adjustable | |

| Rollers: 18 rollers ( based on drawing ) | |

| Material for Rollers: GCr15, polished, quenched HRC55-60 | |

| Motor Power: 15 Kw | |

| Roller Diameter: 76mm | |

| Transmission Type: Chain Transmission | |

| Appearance Size: About 4500mm*1200mm * 1500mm | |

| Total Weight: About 6T | |

| Hydraulic Cutting | Cutting Type: Hydraulic, automatic cutting |

| Blade Material: Cr12 with polished, quenched HRC 60-62 | |

| Power: 3KW | |

| Control System | Electrical Control: PLC Frequency Control System,touch screen |

| Voltage: 380V/50Hz/3Ph(or custom) | |

| Length Error: ±1mm | |

| Output Table | It is simple and used to load finished product |

| Length: 4m ( or custom) |

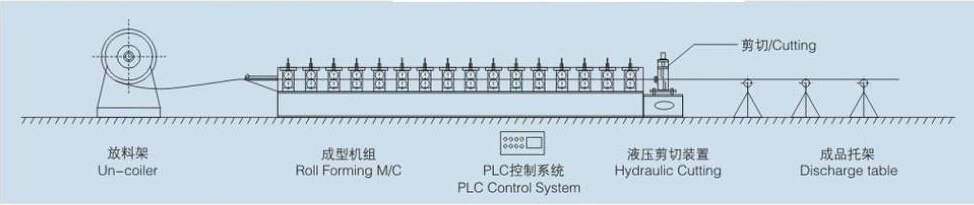

4. Door frame roll forming machine layout

5. Door frame sketch

6. Our service

Door frame roll forming machine Install and Training:

If buyers come to our factory to inspect, the training to install and operate is provided face to face.

If not, manual and video is provided to show how to install and operate.

After-sale Service:

We provide 12-hour online service for our customers. Phone: +86 15821208506

a .The seller will debug the machines freely in China, and the traffic expense in China of the technique people will be paid by the seller.

When technique men go to the buyer's place to debug the machines, the buyer should pay the

expense of accommodation, and round-trip tickets for the seller’s men. and pay the technician USD60 per day.

b. If the buyer sends people to receive the training of the operation given by the seller, during the training period, the seller should pay the expense of accommodation, and traffic for the buyer's men.

7. Delivery