Jiangsu Lebron Machinery Technology Co., Ltd. |

|

Automatic control system Corrugated Sheet Roll Forming Machine new type 2018

1. Product Description

| 1. Suitable material | Color steel sheet , galvanized steel sheet,aluminum sheet |

| 2. Installation Dimension (L*W*H): | 6.5m*1.5m*1.4m |

| 3. Main motor power | 3KW with Cycloidal reducer |

| 4. Hydraulic station power | 3KW |

| 5. Hydraulic oil pump | CB-E 310 |

| 6. Thickness of material | 0.2mm~0.8mm |

| 7. Diameter of principal axis | Φ70-90mm |

| 8. Material expand width | 1000,1200,1250mm |

| 9. Electric tension | 380V 3phase 50HZ or as the customer's requirements |

| 10. Material of roller | High grade 45# forged steel plated with hard chrome plating |

| 11. Controlling system | PLC |

| 12. Processing speed | 3-6m/min |

| 13. Processing precision within | 1.00mm (depend on design) |

| 14. Material of cutting blade | Cr12 mould steel with quenched treatment |

| 15. Kind of drive | 0.6 inch chain link bearing model 6210 |

| 16. Roller station | 8-20 Rollers |

| 17. Roller material | high grade 45#steel; Cr12 quenching |

| 18. Leak frame load-bearing | 4.6T |

2. Description of corrugated tile roll forming machine

This corrugated roofing sheet roll forming machine uses galvanized steel sheet, colored armor plate or aluminum plate as the material plate.

The products of it are used as the roof tile and wall panel outside of building, to increase the beauty and durability of the roof tile and wall panel.

Our corrugated roof sheet roll forming machines are customized, if you have the roof tile sheet drawings, please let me know, then we can produce the machine for you.

And if you do not have the drawings, we can send you our drawing catalogue for you choose the one you think is suitable for you

LBM factory is manufacturing high quality corrugated roof sheet roll forming machines, and exported to the foreign countries such as India, Malaysia, Indonesia, Vietnam, Thailand, Russia, Syria, Saudi Arabia, Singapore, etc.

3. Our after-sale service:

Our products are widely used in various industrial factory ,beauty spot, holiday village building, hotel,exhibition ,easy steel building manufacturing ,and have features such as nice appearance and durable.

Within in one year if any parts go broken we will send new ones to replace for free,after the warranty period,we will help you repair the machine ,you only responsible for the labour and parts if the machine have some problems.

4. FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

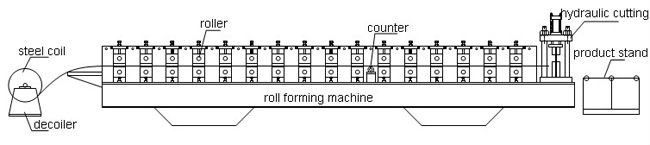

5. Corruaged roof roll forming machine flow chart

6. Advantage:

- This EU type of light gauge steel roll forming machine line include 3 tons of manual decoiler, roll forming host, PLC control system, hydraulic cutting system and output table

- The manual decoiler is free for each machine, it can hold 3 tons of strips, and normally the space between manual decoiler and the machine is 3 meters.

- Feeding table has 1 row of roller to make the strip flat, and the roll forming host can produce the light keels as per customer's request.

6. Picture