Jiangsu Lebron Machinery Technology Co., Ltd. |

|

Hydraulic Cutter Solar Support Strut Channel Roll Forming Machine Full Automatic

1. Description of strut channel roll forming machine

Strut channel is a standardized formed structural system used in the construction and electrical industries for light structural support, often for supporting wiring, plumbing, or mechanical components such as air conditioning or ventilation systems.

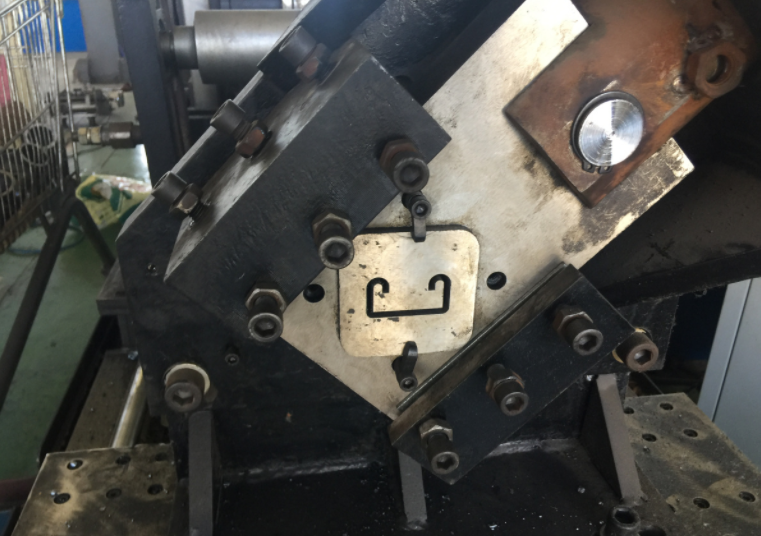

A strut is usually formed from a metal sheet, folded over into an open channel shape with inwards-curving lips to provide additional stiffness and as a location to mount interconnecting components. Increasingly, struts are being constructed from fiberglass, a highly corrosion-resistant material that's known for its lightweight strength and rigidity.[4] Struts usually have holes of some sort in the base, to facilitate interconnection or fastening strut to underlying building structures.

The solar strut channel roll forming machine is designed for producing the main sizes of different strut channel supports. The whole machine unit main including Uncoiler, Entry Beach, Punch unit, Roll Forming Unit, Shearing Mechanism, Hydraulic System, Electric Control System.

2. Main technical parameters of strut channel roll forming machine

| No. | Item | Description |

| 1 | Suitable Material | GI, GL, Al, CR Coil or Strip |

| 2 | Thickness | 2.0/2.5mm |

| 3 | Profile | U/C Channel |

| 4 | Machine Weight | Approx 14 Ton |

| 5 | Frame | 400# H steel |

| 6 | Drive mode | Differential box transmission |

| 7 | Material of rollers | GCr12MoV |

| 8 | Material of shafts | 45# steel with tempering |

| 9 | Diameter of shafts | φ80mm |

| 10 | Number of rollers | 20 rollers |

| 11 | Forming speed | 10m/mins |

| 12 | Main power | 22kw |

| 13 | Voltage | 380V/50Hz/3Ph |

| 14 | Control system | PLC control system |

3. Main components of strut channel roll forming machine

| No. | Item | Description |

| 1 | Manual Uncoiler | Uncoiling width: 1250mm Inner diameter: 450-550mm Capacity: 5T |

| 2 | Entry Beach | guarantee the strips are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron. |

| 3 | Punching system | Hydraulic punching, Cr12 steel, contribute with weld. Adopt Servo control system. Power:3kw |

| 4 | Main Roll Forming System | Adopt welded sheet structure, motor reducer drive, gear transmission. Rollers do polishing, hard plating, heat treatment and galvanizational treatment . The polished surface and the heat treatment towards the molds keep the molding plate surface smooth and not easy to be marked when stamping. |

| 5 | Shearing Mechanism | Automatic cutting controlled by PLC Adopt the hydraulic drive and automatic location to decide the dimension, and cut the target products. Material of blades: Gcr12 steel, quenched Hydraulic power Frame: Pillar style with rack & pinion system Stroke switch : non-contact photoelectric switch |

| 6 | Hydraulic system | Hydraulic oil: 46# Power: 5.5KW Components: The system includes a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes, two sets of electromagnetism valves |

| 7 | Electric Control System

| Delta PLC, transducer, touch panel Other electric element are Delta brand Equipped movable switch, air break, radiator, transformer & electric leakage protector for operation convenience and safety. |

| 8 | Counter | One counter gauges length, pulses, and decides length. Omron encoder for length measurement. |

4. Quality Guarantee

The Seller shall guarantee the goods with materials and workmanship in accordance with the required on the drawings, brand new, unused and correspond in all respects with the quality, specification and performance as stipulated in drawings and guarantee a good smooth operation for 12 months after the date of shipment (except consumables). This guarantee excludes the parts that require normal plant maintenance. The guarantee is strictly limited to the repairing and the replacing of the mechanical parts supplied by us found to be defective provided that failure has occurred during the ordinary use of the equipment and it is not accepted and claim due to damage to people, property or loss of production.