Jiangsu Lebron Machinery Technology Co., Ltd. |

|

European Ce Cheap Auto Metal Downspout Roll Forming Machine Hydraulic Cutting

1. Downpipe roll forming machine description

This downpipe roll forming machine is for steel sheet or aluminum sheet cold-form industries. It can roll-forming the steel sheet according to customer’s requirement continuously, automatically cut to length.

The equipment adopts PLC control, AC frequency and adjusting the speed technology, and it realize the continuous automatically production, therefore, it is really a new type of energy-saving and high-effective producing equipment for metal downpipe.

Our downpipe roll forming machine has many advantages, just like high forming speed, low noise, stable transmission, easy operation, good appearance and so on.

2. Technical details of down pipe roll forming machine

| Brand Name | LBM |

| Voltage | 380V or 220V |

| Warranty | 18 month |

| Roller | 20rows |

| Type | Tile Forming Machine |

| Forming speed8-20 | 8-20 m/min |

| Dimension(L*W*H) | 15000mm*1500mm*1500mm |

| Base | 300H steel |

| Diameter of shaft | 70mm |

| Roller material | 45# steel or hard chromium plating |

| Cutting type | Hydraulic cutting type |

| Cutting blade | Cr12 |

| Main motor Power(Kw) | 8.0KW |

| Weight | 3-4t |

| Color | As your request |

| Material thickness | 0.3-0.7mm or As your request |

| Material width | 330mm or As your request |

| Transmission type | Chain transmission+deceleration motor |

3. Main components of the downpipe roll forming machine

| The equipment includes: | |

| Roll forming machine, | 1 set |

| Hydraulic cutter | 1 set |

| Electrical control system | 1 set |

| Hydraulic system | 1 set |

| Hydraulic system | 2 PC 1m*1m |

| Manual decoiler | 1 set Max loading 5Ton |

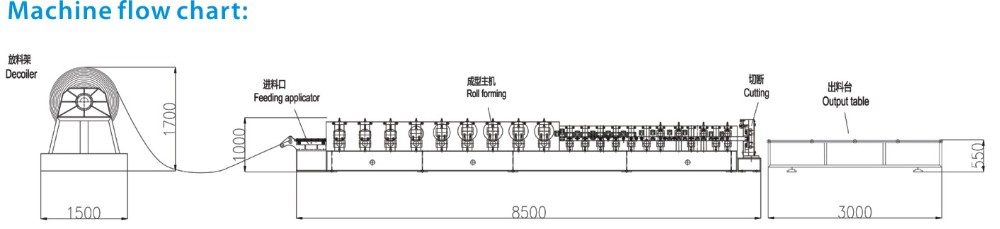

4. Downpipe roll forming machine flow chart

5. Our service

1. Product quality control and delivery time is strictly

controlled;

2. Direct manufacturing factory offering competitive price;

3. All the inquiries will be replied within 12 hours;

4. OEM & ODM service are available;

5. Providing first-class after-sales services to the customers.

6. Installation and training:

If buyers visit our factory and check the machine, we will teach

you how to install and use the machine and also train your

workers/technician face to face.

Without visiting,we will send you user manual and video to teach

you to install and operate.

If buyer needs our technician to go to your local factory, our

engineers can go to your place to make the installation

7. Product Picture