Jiangsu Lebron Machinery Technology Co., Ltd. |

|

Construction Automatic Light Steel Keel Roll Forming Machine Mitsubishi PLC Control

1. Light steel keel roll forming machine description:

Metal Ceiling Industry Forming Machine is used for producing profiles of the ceilings. This product is widely used in many kinds of industrial factories, civilian buildings, and wallboard for the attached part product. It has the advantages of pretty appearance, durable using and so on.

The Metal Ceiling Industry Forming Machine can produce the metal ceilings continuously. Comparing with producing by the bending machines, the former is more effective, saving manual costs.

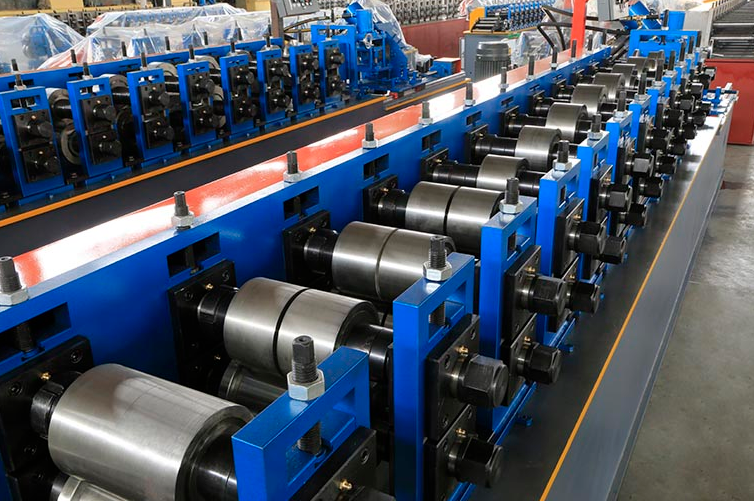

The complete Metal Ceiling Industry Forming Machine including the Decoiler, Main Roll Forming Machine, The PLC control system and Ran-out tables. Our roll forming machine equipped with the computer control system. You just need to program in the computer the piece and length you need, then the roll forming machine produces it automatically. The machine is easy to operate and operate stably.

2. Technical parameters of light steel keel roll forming machine

| Suitable Raw Material | |

| Material | Galvanized Steel Coils |

| Thickness | 0.3-0.8mm |

| Coil width | According to products size |

| Yield strength | 235Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | 13 |

| The diameter of forming rollers shafts | 55mm |

| Roll Forming Speed | 8-10m/min |

| Production Speed | 4-6m/min |

| Forming rollers material | GCR15 mold steel, with quenched treatment |

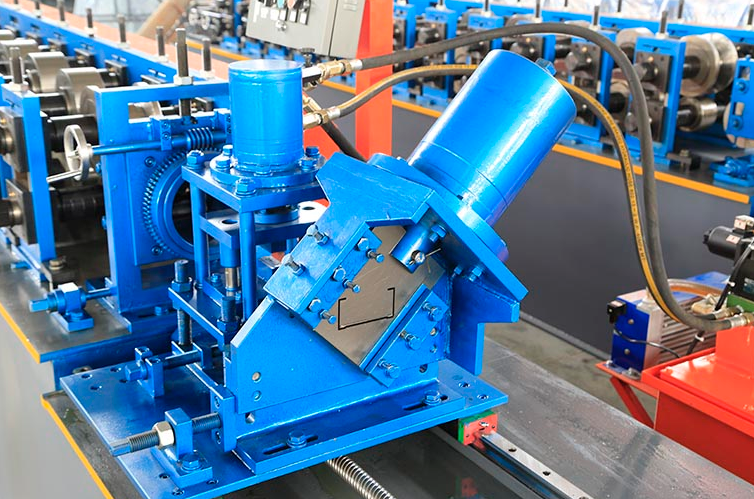

| Cutter material | CR12 mold steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric power requirement | Main motor power: 15kw |

| Hydraulic unit motor power: 5.5kw | |

| Electric voltage | According to customers requirement |

3. Main components of the light steel keel roll forming machine

| No. | Name | Unit | Qty |

| 1 | Decoiler | set | 1 |

| 2 | Entry Beach | set | 1 |

| 3 | Main Machine for roll forming | set | 1 |

| 4 | Cutting System | set | 1 |

| 5 | punching | set | 1 |

| 6 | Output Table | set | 1 |

| 7 | Control System(PLC) | set | 1 |

| 8 | hydraulic station | set | 1 |