S&G Engineering Solution Lmt. |

|

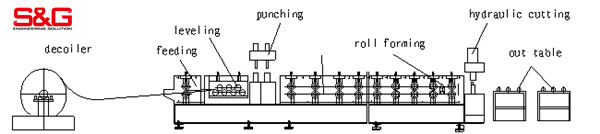

Heavy Duty Rack Roll Forming Machine , Rack Shelving Box Beam Roll Forming,Metal Storage Rack Roll Forming Machine

| Product Name | warehouse storage pallet rack roll forming machine |

| Decoiler | 5ton Hydraulic |

| Leveling Device | 1 set |

| Servo Feeding Device | 1set |

| Punching Machine | 1set |

| Roll Forming Machine | 1 set |

| Hydraulic Station | 1 set |

| Cutting Device | 1 set |

| Run Out Table | 1set |

| Control System | PLC |

Technical Parameter

Forming speed: 0~15M/Min

Product speed: 8~10M/min

Roller material: GCR12 bearing steel

Forming stations: 15 stations + 4 fold ed machine

Shaft diameter: 75mm

Forming structure: Guiding column,chrome-plated

Machine base frame: tube welding structure ,milling gauntry,punch

holes automatic

Transmission type: worm gear box

Motor power of main machine: 7.5KW*2sets

Bearing: HRB brand ,needle roll bearing, taper bearing

Bolt: 8.8 grades

Weight: about 8 tons

Cutting die : Cr12MoV

Profile: +/-0.5mm as drawing

Cutting Length Tolerance + / - 1 mm

Main Components

The Upright Roll Forming Machine Can Apply To Produce All Kinds Of Upright Sheet According To Different Requirement From Customers .

Different Profiles With Different Hole Punching Patterns Are Available According To The Customer’s Requirement & Such Upright Metal Sheet Be Widely Used For Goods Shift Manufacturing .

And The Compact Design Can Save Space And Cost For Our Customers .

The Machine Can Be Adjustable Between Different Upright Metal Sheet With Automatically

The Main Parameters Are As Following :

| No | Items | Unit | Main Specification |

| 1 | Raw Material | / | GI ,GL, PPGI,PPGL,Stainless Steel,Milling Steel ,CR,HR |

| 2 | Material Thickness | mm | 1.5--2.5 |

| 3 | Forming Speed | M/min | 12-15 |

| 4 | Rolling Station | / | 20 Stations ( Depend On The Final Profile From Customer) |

| 5 | Main Power | Kw | 18.5 (With Brand of Simen or Top Brand In China Or Per Customer’s requirement) |

| 6 | Hydraulic Power | Kw | 5.5(With Brand of YUKEN or VIKER or REXROTH or Paefor or Other Brand) |

| 7 | Control System | / | PLC Panasonic / Omron/Simens/Mitsubishi ,Inverter As Yaskawa /Panasonic |

| 8 | Driven Manner | / | Chain Driven |

| 9 | Pneumatic System | Festo / SMC/Parker/CKD/YSC or Customer Required Brand . |

1. Manual uncoiler:

a) Coil inner diameter : 508MM.

b) Coil/strip width: 300- 500MM.

c) Load capacity – 5T

d) Stands on a wheeled base to allow transverse strip adjustment.

2. Strip Feeding guide

a) Strip feed: 300-500MM.

b) Adjustment: Can adjust the minimum strip from one end to the other

3. Rollers:

Gear/ Chain drive. Single chain

Rollers- Hard Chrome coated

Protection covers – for chains

4. Hydraulic cutting:

a) Hydraulic tank capacity: 50kgs dimensions: 50*50*90mm

b) To operate in both manual and automatic modes

5. PLC control system

Roll Formed Pallet Rack Advantages:

Working Flow of Roll Forming Machine

Manual de-coiler-->leveling machine -- roll forming machine

–Cutting device–>Product Stand Tables

After-sales service

Technical Support

Fully providing technology supports both within and after the warranty period. Feed back to our customers at the first time.

Spare Parts

Promptly providing spare parts and wearing parts.

Upgrade

Improve technology and upgrade of equipments.

Other service

Raw Materials

Supply of raw materials made in China with good quality, quick delivery and reasonable price

Finished products purchase

Profile Drawing:

Machine Picture: