S&G Engineering Solution Lmt. |

|

Heavy Duty Warehouse Shelving Rack Beam Roll Forming Machine With Seaming,High Efficient Storage Shelf Rack Roll Forming

Advatage Of Roll Formed Pallet Rack:

Technical Parameter

1. Suitable Plate Material: thickness 1.5-2.0mm, Galvanized steel

2. Working Speed: 12-15meters / min

3. Forming machine: 18 stations

4. Material of Roller: Gcr15, Quench HRC58-62 Plated Chrome

5. Material of Shaft: 45# Advanced Steel (Diameter: 76mm), thermal

refining

6. Driven system: Chain Driven 1.5 inches 20A double chain with

longer shafts

7. Main Power with reducer: 11KW

8. Cutting: Hydraulic Cutting Cr12mov

9. Material of Cutting Knife: Cr12Mov, Quench HRC58-62

10. Hydraulic Station Power: 5.5KW

11. The whole machine is controlled by Panasonic PLC

12 PLC--Panasonic, Japan English and Chinese Language

13. Touch Screen--Panasonic Japan

14. Encoder--Omron, Japan

15. Electric parts--Schneider

16. Outline of main about 7500mm*800mmm*800mm

17. Weight : about 5 tons

Material of Main Equipment

Roller Material: High grade No.45 forged steel, with digital-controlled procession,

Plated with hard chrome.

Active Shaft Material: High grade No.45 carbon wrought steel,which can improve the integrated mechanic feature of the shaft. Shaft diameter is 50mm.

Electric Elements: PLC control panel, transducer imported from Mitsubishi of Japan.

Other elements from famous suppliers in China

Cutter blade and punch dies: Cr12 mould steel with quenched treatment

- No. of Work Station..........................12stations

- Max. Roll shafts Dia..........................76mm

- Overall L x W x H (Approx.)...............3.8M*1.2M*1.6M

- Roller material: GCR15 quenched 58°-62°,chromed

- Outside is cast iron, surface needed polish and paint. Inside is 60# forge and press metal)

- Transducer: Panasonic

- Cages.......................... use the strong steel nets

- Levelling screws on base ............with Thick metal paltes

NEW TYPE Metal Stud and Track Roll Forming Machine(The decoiler/uncoiler)

Usage: It is used to support the steel coil and uncoil it in a turntable way.

Passive uncoil pulled by roll forming system

Loading capacity: 1.5T

Uncoiling width: 300mm

Inner diameter: 450-550mm

NEW TYPE Metal Stud and Track Roll Forming Machine(Main Forming Machine)

Feature : Ensure stability , precision and lifetime.

Length of the main part: about 3800*1150*1400mm

Weight of main part: 3 tons

Voltage : 380V/50HZ3Phase (as customer’s request)

Roller fixer : Guide column

Frame : middle plate welded

Memorial arch frame type

Frame thickness:25mm

Drive mode: gear or chain

Material of rollers: GCr12MoV

Material of shafts: 45# steel with tempering

Diameter of shafts: φ50mm

Number of rollers : 12 rollers

Main power: 3kw(Cycloidal planetary gear speed reducer)

NEW TYPE Metal Stud and Track Roll Forming Machine(Cutting Device)

1. Blade Material: Cr12 steel with quenched treated 60-62°C

2. Cutting system: Cut to length, full automatic

NEW TYPE Metal Stud and Track Roll Forming Machine(Controlling System)

1. Screen: text screen displayer

2. PLC: Taida DVP14ES from Taiwan

3. coder: ENC-1-1-1T-24 from South Korea

NEW TYPE Metal Stud and Track Roll Forming Machine(Hydraulic oil pump)

NEW TYPE Metal Stud and Track Roll Forming Machine(Spare Parts)

Main Components

| No. | Item Name | Quantity | Remark |

| 1 | Manual de-coiler | 1 set | 3 tons |

| 2 | Leveling machine | 1set | Wannan motor |

| 3 | Cutting device | 1 set | Engineer define |

| 4 | Punching device | 2 sets | Hydraulic Prepunching |

| 5 | Roll Forming Machine | 1 set | ¢75mm |

| 6 | Cutter mold | 6 units | Engineer define |

| 7 | Hydraulic station | 1 set | Engineer define |

| 7 | Product stand table | 5 sets | 2 m*5 |

| 8 | Folded machine | 1 set | ¢75mm *4 |

| 9 | Tool Box | 1 box | standard |

| 10 | Books | 1 book | Use manual, Wire diagram, Machine layout drawing, Maintenance book, |

| 11 | Spare parts | 1 set |

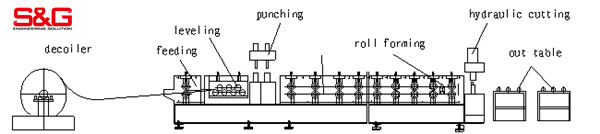

Working Flow of Roll Forming Machine

Manual de-coiler-->leveling machine -- roll forming machine

–Cutting device–>Product Stand Tables

Features of Racking Roll Forming Machine

The punching can be designed according to customers’ requirements.

The storage device will help to coordinate the operation of each

part of this storage rack roll forming machinery so as not to

produce speed conflict.

For different dimensions of racking products, users can adjust the

product dimension by changing the spacer bush in the racking roll

forming machine.

The design of this storage rack roll forming machinery enables the

roll forming part to be changed quickly. That is why only one

machine can produce several different profiles and the forming unit

can be changed in a short time.

We have a professional technical team owning more than 15 years’

working experience.

Our S&G series offers you flexibility, productivity and long lasting stability. Our lines are featured with cassette design (Subjected to client’s requirement), allow you to change quickly a profile to another. A multi-stage punching machine or a standard hydraulic press can be chosen in the punching stage per actual product. A fly shear/Saw is also optional up to the client.

Brief introduction

This cable tray roll forming machine is a professional roll forming machine for steel sheet cold-form industries. It can continuous form the steel sheet according to customer’s requirement, automatically cut to length. This equipment has many advantages, such as high forming speed, low noise, stable transmission, easy operation, good look etc.

This machine is able to roll form two different profile(tray&cap) by adjusting the rollers.

Profile Drawing:

Machine Picture: