S&G Engineering Solution Lmt. |

|

Three Humps Steel Panel Floor Deck Roll Forming Machine CE / SONCAP With Two 15KW Driving Motors

Introduction

This roll forming machine is designed to manufacutre galvanised

steel floor decking panels with a high speed. The finished iron

floor dek panels are with a high strength.

Technical Specifications of Galvanized Steel Floor Dek Making Machine

| Technical Items | Details | |

| Raw Material | Type | Galvanized Steel Coils |

| Width | 1200 mm | |

| Thickness | 0.8-1.2 mm | |

| Yield Strength | 235-345 MPa | |

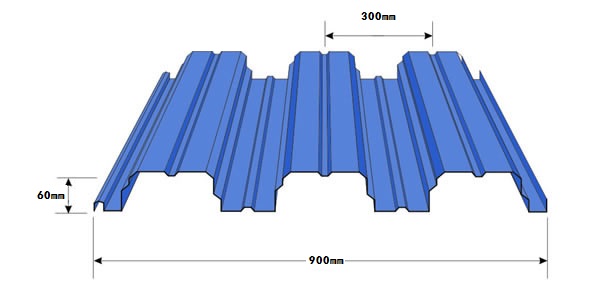

| Finished Products | Cover width | 900 mm |

| Length | Adjustable | |

| Required Power | Voltage | 220V/380V/415V/440V |

| Driving Motor | 22 KW | |

| Cutting Motor | 3 KW | |

| Production Speed | around 900 meters per hour | |

| Coil Decoiler | Type | Un-powered or Powered |

| Capacity | 5 tons or 10 tons | |

| Rolling Stations | 35 sets | |

| Rolling Shaft Diameter | 82 mm | |

| Cutting Type | Post-cutting | |

| Operation System | Mitsubishi PLC, transducer and touching screen | |

| Supporting Tables | 2 sets | |

| Machine Size | Around 18 x 1.6 x 1.6 meters | |

| Machine Weight | Around 19 tons | |

Main Components of Galvanised Steel Floor Decking Making Machine

| No. | Items | Quantity | |

| 1 | Coil Decoiler | 1 set | |

| 2 | Rollformer Machine | Direction Guilder | 1 set |

| Rolling System | 1 set | ||

| Post-cutting Device | 1 set | ||

| 3 | Supporting Tables for Finished Products | 2 sets | |

| 4 | Hydraulic Station for Cutting Device | 1 set | |

| 5 | PLC Control Cabinet | 1 set | |

| 6 | Tools Box with Spare Parts | 1 set | |

Componets Descriptions of Galvanised Steel Floor Decking Sheet

Rollforming Machine

| Coil Decoiler: The maximum capacity of the coil decoiler can hold is 5 tons or 10 tons. It is designed for the coils with 508mm inner-diameter and maximum 1000mm outer-diameter. |

| Direction Guilder: It adopts wheel and screw which are used to regulate the iron stick for direction guilding. |

| Rolling System: The main frame of machine is welded separately and the outside wall is connected by screws after being painted on the surface. The rollers are made by No.45 forged steel of high quality, which are processed by CNC machine and coated with hard chrome to get a long lifespan. The rolling shafts aremade by No.45 carbon wrought steel of high quality, which can improve the integrated mechanic feature of the rolling shafts, then the rolling shafts will be processed by cylindrical grinding machine to ensure the precision of final products. |

| Post-cutting Device: Cutter blade is made by Cr12 mould steel with heating treatment. The cutter’s structure adopts welded frame for good rigidity. The power of cutting action is provided by hydraulic station. |

| Supporting Tables for Finished Products: They are used to support the finished products. It is convenient for the workers to stack the finished products. |

| Hydraulic Station for Cutting Device: The motor and hydraulic accessories are with famous Chinese brand which guarantee the hydraulic station is supplying stable the power for the cutter. |

| PLC Control Cabinet: The control system adopts Mitsubishi PLC, interter, touching screen for all the working actions of the machine. Some parameters, such as product quantity, product length and so on can be set into the PLC controller, then this machine will automatically produce the desired products according to the set parameters. |

| Tools Box with Spare Parts: The tools box contains the necessary tools such as spanners, screwdrivers, pilers, oil pot and useful spare parts such as control buttons, position switches, mini relays, chains and so on. |

Applications:

The finished floor decking panels are widely used in power plants,

factories, warehouse, office, airport

terminals, railway stations, stadiums, supermarkets, logistic centers and other steel structure constructions.

Working Flow of Galvanised Iron Floor Decking Panels Manufacturing Machine

Decoiling----Embossing----Rollforming----Hydraulic Cutting----Finished Floor Decks on Supporting Tables

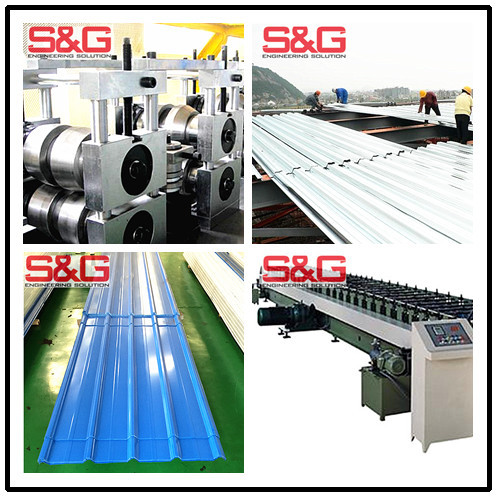

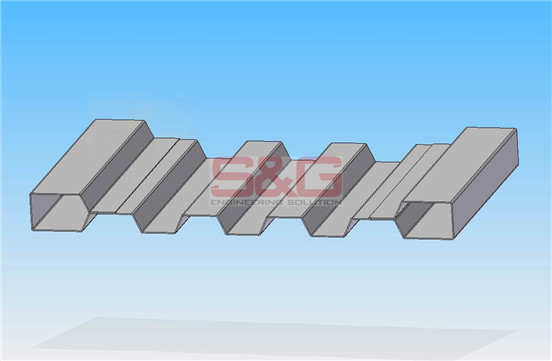

Product Images:

Machine Picture: