S&G Engineering Solution Lmt. |

|

Horizontal Floor Deck Roll Forming Machine Width 1000mm 11KW Power,automatic color steel floor deck tile making machine

Introduction

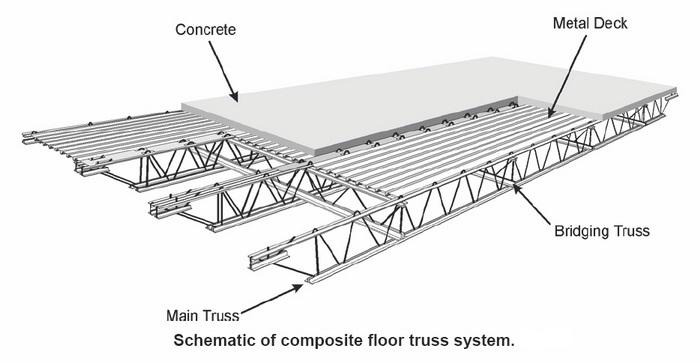

This metal roll forming machine adopts 35 sets of rolling stations to corrugate the galvanized steel sheet into floor deck panels with high humps and embossment on the surface.The metal floor deck made by this cold roll forming machine can be typically used for multi-story buildings, mezzanines, bridge walkways, porches, in-fills, platforms and parking garages, storage facilities, etc. The steel floor deck has a ribbed profile with embossments designed to interlock with concrete slabs, creating a reinforced concrete slab that serves the dual purpose of permanent form and positive reinforcement.

Engineering Project Application of Finished Metal Floor Deck Panels

This metal / steel floor decking making machine is manufactured to produce steel floor decking plates, which have been widely used in facilities such as in modern steel buildings, large factories, and warehouses, etc. The forming process of this equipment is excellent and logical, and finished products enjoy high strength and quality. Besides, we can manufacture floor deck forming machines of different specifications according to practical requirements of our customers. This deck machine is controlled by PLC control system, so it is easy to operate and debug. All famous brand electric parts of this machine ensures stable performance and long span of this machine.

1. Maximum capacity: 5 Ton

2. Maximum width: 1350mm

3. I.D: 460-508mm; O.D: 1500mm

4. Structure: Steel plate and Beam Welded

5. Function: Supporting and uncoiling the steel strips

1. Structure: Wall Panel Type

2. Rollers Station: 32 stations

3. Diameter of Shaft: 90mm

4. Material Of Shaft: 40Cr

5. Material Of Roller: GCr15 HRC58~62 and Chroming of 0.05mm

Thickness

6. Motor Power: 15KW*2

7. Power Transition: by Gears & Chains

8. Speed Control: by Frequency Converter

9. Speed of the machine: 16-20m/min

1. Cutting Type: Hydraulic Cutting, roll forming part stops when cutting the formed products

2. Cutting Moulds: 1 group

3. Material Of Cutting Mold: Cr12mov HRC 60-62

4. Cutting Length And Quantity: Clients Can Set The Length and

Quantity on the PLC Touch Screen

5. Cutting Pressure: 12-16Mpa

6. Hydraulic Station Power: 7.5KW

7. Tolerance Of Cutting Length: +/-2mm

1. The worker input the length and quantity of the product through

touch screen, total 20 groups

2. Computer Control System: Panasonic PLC

3. Encoder: Omron Brand

4. Frenquency Converter: Yaskawa

5. Touch Screen: MCSG

6. Controlled System Power: Overload Protection

7. Pressure Of Hydraulic Station: ≧12Mpa

8. Current: 380V, 50Hz, 3 Phase

Simple unpowered, support and collecting the formed floor decks. High quality angle steel welded.

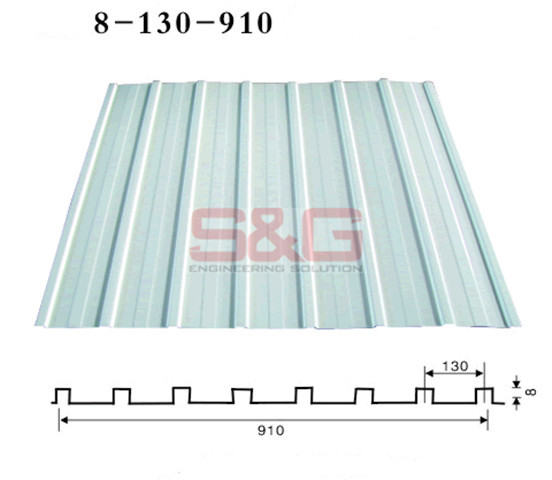

Technical Specifications of Galvanised Steel Floor Decking Panel Rollforming Line

| Metal deck roll forming machine | |

| Suitable material | galvanized sheet,etc |

| Steel Thickness | 0.8-1.2mm |

| Steel feeding width | 1000-1250mm |

| Forming Speed | 10-12m/min |

| Roller stands | 30-36stands |

| Roller Material | 45# steel, coated with chrome |

| Hydraulic cutting Power | 18kw |

| Hydraulic pressure | 5kw |

| Hydraulic pressure Mpa | 12 Mpa |

| Voltage | 380V, 50HZ,3 phase |

| Tolerance | 1.5mm |

| Material of cutting | Cr12 |

| Control system | PLC(Panasonic)&Encoder(O mron)&Inverter(YASKAWA) |

| Dimension | customized |

Metal Deck Floor Roll forming Machine

Main components

Working Flow of Galvanised Iron Floor Decking Panels Manufacturing Machine

Decoiling----Embossing----Rollforming----Hydraulic Cutting----Finished Floor Decks on Supporting Tables

Machine Picture:

Product Image: