S&G Engineering Solution Lmt. |

|

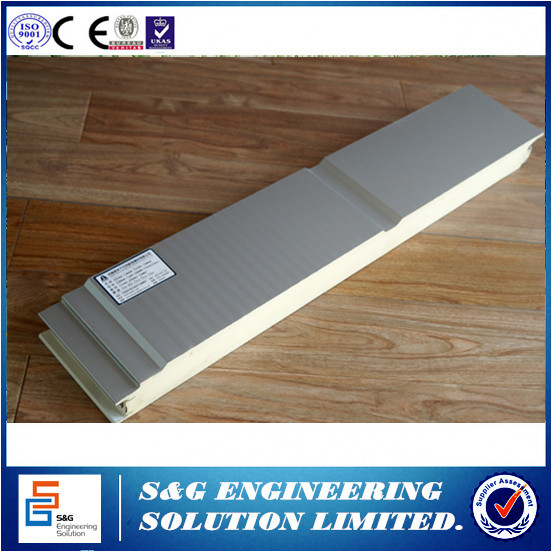

Continuous PU (Polyurethane) Sandwich Panel Production Line,Thickness:0.3-0.6 mm,colored steel plate, galvanized plate

S&G - the professioanl manufacturer for insulated sandwich panel production line ,and as we are the subcompany of Superlift ,who have more than 10 years of PU sandwich panel production experience .So we not only could provide u the advanced PU sandwich panel cpntinuous production line ,but also could supply u with the set of sandwich panel production crafts without charge .

Polyurthane Sandwich panel production line is used to product all kinds of insulated sadnwich panel ,such as,wall panel ,roof panel ,cold room panel and garage door panel ,it is multifunctional . Besides ,it also is full automatic and continuous ,adpots PLC controlling system ,only need 6 workers to operate ,could help boss save alot o labor .

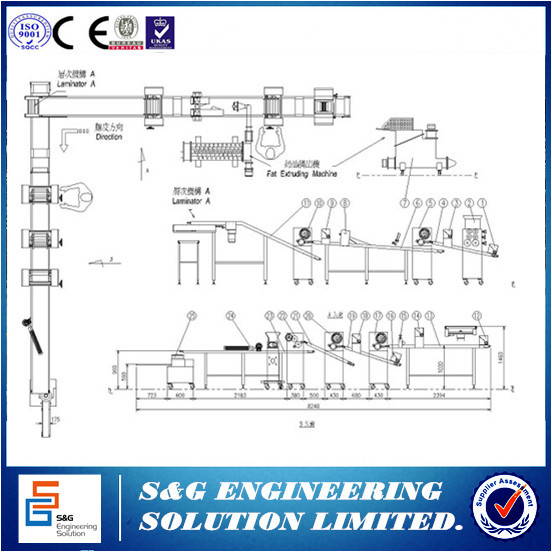

It is consisted of the following equipments :decoiler ,roll forming machine ,heating machine ,PU foaming machine ,double belt laminating machine ,automatic cutter .The panel cooling machine ,automatic stacker and packing machine are optional .

Moreover,both the decoiler, roll forming machine, the laminating system and cutter can work independently.

Component : Hydraulic Uncoiler

Steel sheet transverse shear device and Film-covering machine

Roll forming machine

Pre-heating device

PU foaming machine

Double belt conveyor

Auto tracking cutter

Panel Cooling machine

Auto Stacker

Packing machine

Electrical sontrol system

Introduction of production line:

There are upper and lower roll forming machine and quick change system, it is possible to produce various profiles to meet diversified demands.

| Main Techincal specification: | ||||||||||||||||||

1. Decoiler Bearing :5T / 7.5T / 10T Speed of uncoiling :0--12m/min(adjustable) Inner diameter of coiler : Ø508 , Ø610mm Outer diameter of coil:≤1200mm

2. Roll forming machine

3. Heating machine

Way of heating :gas or electricity

4. Double belt laminating machine

Total length :18--36m Moving speed:0--12m/mim

5. Auto tracking cutter

Horizontal moving length: 6m

| ||||||||||||||||||

| Product Usage: | ||||||||||||||||||

| Sandwich panels are widely used as the roof and wall of factory, warehouse, garage, exhibition center, cinema, theatre, gymnasium, civil construction, stadium, cold storage, villa garage door and industry door etc. |

Other Spare part | Weight | About 25 ton |

| Dimension | 42000mm * 3600mm * 3300mm | |

| Main body color | As required | |

| Voltage | 380v/50hz/3ph(or as required) | |

| Suitable working temperature | About 25℃ | |

| Spare cutting blade | One piece | |

| Fuse | 2 pieces | |

| Relay | 2 pieces | |

| Travel switch | 2 pieces | |

| Solenoid valve | 1 pieces |

Product Features

1.Beautiful appearance, low noise, high efficiency

2.Multiple function: could produce 4 kinds of panel ,wall pane

,roof panel ,cold room panel ,and garage door panel .

3.The line employs advanced PLC and sets the panel length and cuts

the panel automatically.

4.The main body is welded with type "H" section steel as its

material,strong strength.

5.The roll forming machine is adjustable ,the suitable width range

is 600-1250mm

6.The roller matrial is medium carbon alloy steel ,with high quality .

7.The length of double belt laminating machine could be made according to customers needs .

Application

The products of this line are widely used as the roof and wall of

factory, warehouse, garage,

exhibition center, cinema, theatre, gymnasium, civil construction,

stadium, cold storage, etc.

Our Advantage

Production line:

Profile Drawing:

Machine Picture: