Bicheng Electronics Technology Co., Ltd |

|

Verified Suppliers

|

|

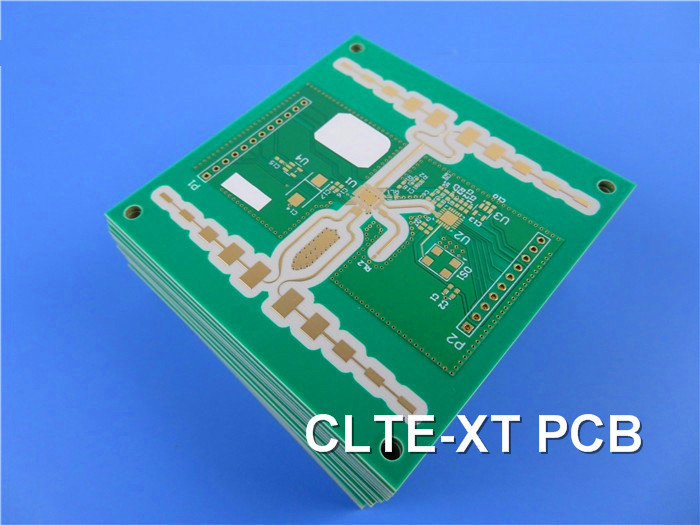

Introducing our newly shipped PCB built on the CLTE-XT material by Rogers. Supplied to provide exceptional performance and reliability, the CLTE-XT laminate combines micro-dispersed ceramic filler, PTFE, and woven fiberglass reinforcement. This unique composition offers the lowest insertion loss, improved loss tangent, and superior dimensional stability in its class.

The CLTE-XT PCB features a dielectric constant (DK) of 2.94 at 10GHz, 23°C @ 50% RH, ensuring precise signal transmission and minimizing signal loss. With a dissipation factor of 0.0010 at 10GHz, 23°C @ 50% RH, this PCB delivers excellent signal integrity, maintaining the quality of your electrical signals.

| Properties | CLTE-XT | Units | Test Conditions | Test Method | |

| Electrical Properties | |||||

| Dielectric Constant | 2.94 | - | 23˚C @ 50% RH | 10 GHz | IPC TM-650 2.5.5.5 |

| Dissipation Factor | 0.0010 | - | 23˚C @ 50% RH | 10 GHz | IPC TM-650 2.5.5.5 |

| Dielectric Constant (design) | 2.93 | - | C-24/23/50 | 10 GHz | Microstrip Differential Phase Length |

| Thermal Coefficient of Dielectric Constant | -8 | ppm/˚C | -50°C to 150°C | 10 GHz | IPC TM-650 2.5.5.5 |

| Volume Resistivity | 4.25x10⁸ | Mohm-cm | C-96/35/90 | - | IPC TM-650 2.5.17.1 |

| Surface Resistivity | 2.49x10⁸ | Mohm | C-96/35/90 | - | IPC TM-650 2.5.17.1 |

| Electrical Strength (dielectric strength) | 1000 | V/mil | - | - | IPC TM-650 2.5.6.2 |

| Dielectric Breakdown | 58 | kV | D-48/50 | X/Y direc- tion | IPC TM-650 2.5.6 |

| PIM (For antenna only) | - | dBc | - | 50 ohm 0.060" | 43dBm 1900 MHz |

| Thermal Properties | |||||

| Decomposition Temperature (Td) | 539 | ˚C | 2hrs @ 105˚C | 5% Weight Loss | IPC TM-650 2.3.40 |

| Coefficient of Thermal Expansion - x | 12.7 | ppm/˚C | - | -55˚C to 288˚C | IPC TM-650 2.4.41 |

| Coefficient of Thermal Expansion - y | 13.7 | ppm/˚C | - | -55˚C to 288˚C | IPC TM-650 2.4.41 |

| Coefficient of Thermal Expansion - z | 40.8 | ppm/˚C | - | -55˚C to 288˚C | IPC TM-650 2.4.41 |

| Thermal Conductivity | 0.56 | W/(m.K) | - | z direction | ASTM D5470 |

| Time to Delamination | >60 | minutes | as-received | 288˚C | IPC TM-650 2.4.24.1 |

| Mechanical Properties | |||||

| Copper Peel Strength after Thermal Stress | 1.7 (9) | N/mm (lbs/ in) | 10s @288˚C | 35 μm foil | IPC TM-650 2.4.8 |

| Flexural Strength (MD, CMD) | 40.7, 40.0 (5.9, 5.8) | MPa (ksi ) | 25˚C 3˚C | - | ASTM D790 |

| Tensile Strength (MD, CMD) | 29.0, 25.5 (4.2, 3.7) | MPa (ksi ) | 23C/50RH | - | ASTM D638 |

| Flex Modulus (MD. CMD) | 3247, 3261 (471, 473) | MPa (ksi ) | 25C 3C | - | ASTM D790 |

| Dimensional Stability (MD, CMD) | -0.37, -0.67 | mm/m | 4 hr at 105˚C | - | IPC-TM-650 2.4.39a |

| Physical Properties | |||||

| Flammability | V-0 | - | - | C48/23/50 & C168/70 | UL 94 |

| Moisture Absorption | 0.02 | % | E1/105+D24/23 | - | IPC TM-650 2.6.2.1 |

| Density | 2.17 | g/cm³ | C-24/23/50 | - | ASTM D792 |

| Specifc Heat Capacity | 0.61 | J/g˚K | 2 hours at 105˚C | - | ASTM E2716 |

| NASA Outgassing | 0.02 / 0.00 | % | TML/CVCM | ASTM E595 | |

One of the outstanding advantages of the CLTE-XT material is its dimensional stability. It exhibits a low coefficient of thermal expansion (CTE) with an X-axis CTE of 12.7ppm/°C, Y-axis CTE of 13.7ppm/°C, and Z-axis CTE of 40.8ppm/°C. This dimensional stability ensures the reliability and integrity of the PCB, even in varying temperature conditions.

The CLTE-XT PCB offers numerous benefits for electronic designs. It provides high plated through-hole reliability, ensuring secure electrical connections. With repeatable lot-to-lot performance, you can rely on consistent results across multiple production runs. Additionally, the CLTE-XT material reduces circuit losses without compromising dimensional stability, leading to optimized performance. Its stable dielectric constant with temperature changes also minimizes stress on ceramic active devices, enhancing their reliability.

This PCB is a 2-layer rigid board with a copper layer thickness of 35 μm on both sides. The core of the CLTE-XT material measures 0.508 mm (20mil). The board dimensions are 53.18mm x 76.04mm, providing sufficient space for your circuit design. With a minimum trace/space of 4/5 mils and a minimum hole size of 0.4mm, you can achieve intricate and precise routing, enabling efficient component placement and assembly.

| PCB material: | Ceramic/PTFE Microwave Composite |

| Designation: | CLTE-XT |

| Dielectric constant: | 2.94 |

| Layer count: | Sinlge-sided PCB, Double-sided PCB, Multi-layer PCB, Hybrid PCB |

| Dielectric thickness: | 5.1mil(0.130mm), 9.4mil (0.239mm), 20mil (0.508mm), 25mil(0.635mm), 30mil(0.762mm), 40mil(1.016mm), 45mil(1.143mm), 59mil(1.499mm), 60mil(1.524mm) |

| Copper weight: | 1oz (35µm), 2oz (70µm) |

| PCB size: | ≤400mm X 500mm |

| Solder mask: | Green, Black, Blue, Red, Yellow etc. |

| Surface finish: | Immersion gold, HASL, Immersion silver, Immersion tin,ENEPIG, Bare copper, OSP, Pure gold plated etc.. |

This PCB has a finished board thickness of 0.6mm and a finished copper weight of 1oz (1.4 mils) on the outer layers. The via plating thickness is 20 μm, ensuring reliable electrical connections. The surface finish is immersion silver, offering excellent solderability and corrosion resistance.

The top silkscreen is white, facilitating easy component identification. The bottom silkscreen is not included for a clean and professional appearance. The top solder mask is green, while the bottom solder mask is not applied, allowing for customized soldering and rework as needed.

To guarantee exceptional quality and reliability, each PCB undergoes a 100% electrical test before shipment. The provided artwork format for the PCB is Gerber RS-274-X, a widely accepted standard in the industry. The CLTE-XT PCB meets IPC-Class-2 standards, ensuring high-quality manufacturing.

The CLTE-XT PCB is available worldwide, ensuring accessibility for customers globally. Its exceptional performance and reliability make it ideal for various applications, including advanced driver assistance systems (ADAS), patch antennas, phased array antennas, and power amplifiers.

Experience the superior performance and reliability of the CLTE-XT PCB in your electronic projects and unlock the full potential of your designs with its exceptional signal integrity and dimensional stability.