Bicheng Electronics Technology Co., Ltd |

|

Verified Suppliers

|

|

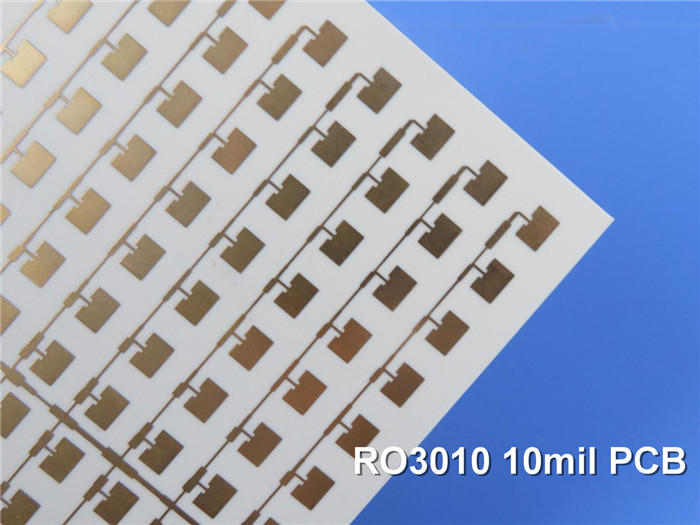

Today, we are happy to share our newly shipped PCB based on RO3010 materials.

1. RO3010 Introduction:

Rogers RO3010 laminates are advanced circuit materials that utilize

ceramic-filled PTFE composites. These laminates offer a higher

dielectric constant with excellent stability. They are

competitively priced products known for their exceptional

mechanical and electrical stability, making them suitable for a

wide range of applications across various frequencies. RO3010

laminates simplify the design of broadband components and are

particularly well-suited for circuit miniaturization.

2. Features:

RO3010 laminates are composed of ceramic-filled PTFE composites.

They exhibit a dielectric constant of 10.2 +/- 0.30 at 10 GHz and

23°C, along with a low dissipation factor of 0.0022 at the same

frequency and temperature. With a low coefficient of thermal

expansion ranging from 13 ppm/°C to 16 ppm/°C (-55 to 288 °C) in

the X, Y, and Z axes, RO3010 laminates demonstrate excellent

dimensional stability. They have a high thermal decomposition

temperature exceeding 500°C and a thermal conductivity of 0.95

W/mK. RO3010 laminates also boast a low moisture absorption rate of

0.05% and can operate in the temperature range of -40℃ to +85℃.

| RO3010 Typical Value | |||||

| Property | RO3010 | Direction | Units | Condition | Test Method |

| Dielectric Constant,εProcess | 10.2±0.05 | Z | 10 GHz/23℃ | IPC-TM-650 2.5.5.5 Clamped Stripline | |

| Dielectric Constant,εDesign | 11.2 | Z | 8GHz to 40 GHz | Differential Phase Length Method | |

| Dissipation Factor,tanδ | 0.0022 | Z | 10 GHz/23℃ | IPC-TM-650 2.5.5.5 | |

| Thermal Coefficient of ε | -395 | Z | ppm/℃ | 10 GHz -50℃to 150℃ | IPC-TM-650 2.5.5.5 |

| Dimensional Stability | 0.35 0.31 | X Y | mm/m | COND A | IPC-TM-650 2.2.4 |

| Volume Resistivity | 105 | MΩ.cm | COND A | IPC 2.5.17.1 | |

| Surface Resistivity | 105 | MΩ | COND A | IPC 2.5.17.1 | |

| Tensile Modulus | 1902 1934 | X Y | MPa | 23℃ | ASTM D 638 |

| Moisture Absorption | 0.05 | % | D48/50 | IPC-TM-650 2.6.2.1 | |

| Specific Heat | 0.8 | j/g/k | Calculated | ||

| Thermal Conductivity | 0.95 | W/M/K | 50℃ | ASTM D 5470 | |

| Coefficient of Thermal Expansion (-55 to 288℃) | 13 11 16 | X Y Z | ppm/℃ | 23℃/50% RH | IPC-TM-650 2.4.4.1 |

| Td | 500 | ℃ TGA | ASTM D 3850 | ||

| Density | 2.8 | gm/cm3 | 23℃ | ASTM D 792 | |

| Copper Peel Stength | 9.4 | Ib/in. | 1oz,EDC After Solder Float | IPC-TM 2.4.8 | |

| Flammability | V-0 | UL 94 | |||

| Lead-free Process Compatible | Yes | ||||

3. Benefits:

One of the notable benefits of RO3010 laminates is their

dimensional stability, with the expansion coefficient matched to

that of copper. This characteristic enhances the reliability and

performance of the laminates. Additionally, RO3010 laminates are

cost-effective, thanks to their economical laminate pricing

resulting from a volume manufacturing process. They are also

suitable for use in multi-layer board designs, providing

flexibility in various applications.

4. PCB Stackup:

For this 2-layer rigid PCB, the stackup consists of a copper layer

with a thickness of 35 μm, followed by the RO3010 substrate with a

thickness of 10mil (0.254mm), and another copper layer with a

thickness of 35 μm.

5. PCB Construction Details:

This PCB has a board dimensions of 80.1mm x 56.74 mm for a single

piece. The minimum trace/space is 4/4 mils, and the minimum hole

size is 0.3mm. There are no blind vias in this configuration. The

finished board thickness is 0.37mm, and the outer copper layers

have a weight of 1 oz (1.4 mils). The via plating thickness is 20

μm. The surface finish is immersion gold, and the top silkscreen is

white, while no silkscreen or solder mask is applied to the bottom

layer. A 100% electrical test is conducted to ensure the quality of

the PCB before shipment.

6. PCB Statistics:

This PCB includes 24 components and a total of 71 pads. Among these

pads, 51 are through-hole pads, and 23 are top surface-mount

technology (SMT) pads. There are no bottom SMT pads. The design

features 67 vias and consists of 3 nets.

7. Supplied Artwork Type: Gerber RS-274-X

8. Accepted Standard: IPC-Class-2

9. Availability: RO3010 laminates are available worldwide, ensuring accessibility for various markets.

10. Typical Applications:

RO3010 PCBs find application in a wide range of industries and

products. They are particularly suitable for automotive radar

applications, global positioning satellite antennas, cellular

telecommunications systems (including power amplifiers and

antennas), patch antennas for wireless communications, direct

broadcast satellites, cable systems for data link, remote meter

readers, and power backplanes. The exceptional electrical and

mechanical properties of RO3010 laminates make them reliable and

versatile for these applications.