Bicheng Electronics Technology Co., Ltd |

|

Verified Suppliers

|

|

Sharing a new RF PCB made of TU-768 material. The TU-768 laminate by Taiwan Union is a high-Tg (glass transition temperature) and high thermal reliability laminate designed to meet rigorous performance requirements. It is accompanied by TU-768P, a matching prepreg for enhanced functionality. These laminates and prepregs are constructed using high-quality woven E-glass coated with an epoxy resin system, offering UV-block characteristics and compatibility with automated optical inspection (AOI) processes. The TU-768 series is well-suited for applications that demand resilience against thermal cycles and extensive assembly work. Notably, TU-768 laminates exhibit exceptional CTE (coefficient of thermal expansion), superior chemical resistance, thermal stability, and CAF (conductive anodic filament) resistance properties.

Key Features:

- Dk (dielectric constant) of 4.3 at 10GHz

- Dissipation factor of .0023 at 10GHz

- CTE x-axis of 11-15 ppm/°C, CTE y-axis of 11-15 ppm/°C

- Coefficient of thermal expansion matched to copper

- Decomposition Temperature (Td) of 350 °C TGA

- Tg (glass transition temperature) of 180°C

- High thermal reliability with T260 >60 min, T288>15 min,

T300 >2 min

Benefits:

- Compatible with lead-free processes

- Excellent coefficient of thermal expansion for stability

- Anti-CAF (conductive anodic filament) property for improved

reliability

- Superior chemical and thermal resistance

- Fluorescent properties enable AOI (automated optical inspection)

- Resistant to moisture-related issues

| Typical Values | Conditioning | IPC-4101 /126 | |

| Thermal | |||

| Tg (DMA) | 190°C | ||

| Tg (DSC) | 180°C | > 170°C | |

| Tg (TMA) | 170°C | E-2/105 | |

| Td (TGA) | 350°C | > 340°C | |

| CTE x-axis | 11~15 ppm/°C | N/A | |

| CTE y-axis | 11~15 ppm/°C | E-2/105 | N/A |

| CTE z-axis | 2.70% | < 3.0% | |

| Thermal Stress,Solder Float, 288°C | > 60 sec | A | > 10 sec |

| T260 | > 60 min | > 30 min | |

| T288 | > 20 min | E-2/105 | > 15 min |

| T300 | > 2 min | > 2 min | |

| Flammability | 94V-0 | E-24/125 | 94V-0 |

| DK & DF | |||

| Permittivity (RC 50%) @10GHz | 4.3 | ||

| Loss Tangent (RC 50%) @10GHz | 0.018 | ||

| Electrical | |||

| Permittivity (RC50%) | |||

| 1GHz (SPC method/4291B) | 4.4 / 4.3 | < 5.2 | |

| 5GHz (SPC method) | 4.3 | E-2/105 | N/A |

| 10GHz (SPC method) | 4.3 | N/A | |

| Loss Tangent (RC50%) | |||

| 1GHz (SPC method/4291B) | 0.019 /0.018 | < 0.035 | |

| 5GHz (SPC method) | 0.021 | E-2/105 | N/A |

| 10GHz (SPC method) | 0.023 | N/A | |

| Volume Resistivity | > 1010 MΩ•cm | C-96/35/90 | > 106 MΩ•cm |

| Surface Resistivity | > 108 MΩ | C-96/35/90 | > 104 MΩ |

| Electric Strength | > 40 KV/mm | A | > 30 KV/mm |

| Dielectric Breakdown | > 50 kV | A | > 40 KV |

| Mechanical | |||

| Young’s Modulus | |||

| Warp Direction | 25 GPa | A | N/A |

| Fill Direction | 22 GPa | ||

| Flexural Strength | |||

| Lengthwise | > 60,000 psi | A | > 60,000 psi |

| Crosswise | > 50,000 psi | A | > 50,000 psi |

| Peel Strength, 1.0 oz RTF Cu foil | 7~9 lb/in | A | > 4 lb/in |

| Water Absorption | 0.18% | E-1/105+D-24/23 | < 0.8 % |

PCB Stackup:

This PCB is a 2-layer rigid PCB design with the following

specifications:

- Copper_layer_1: 35 μm

- TU-768 Core: 0.76 mm

- Copper_layer_2: 35 μm

PCB Construction Details:

- Board dimensions: 47.8mm x 47.8mm (1PCS), with a tolerance of +/-

0.15mm

- Minimum Trace/Space: 4/4 mils, allowing for precise circuitry

- Minimum Hole Size: 0.2mm, providing flexibility for component

placement

- No blind vias, simplifying the manufacturing process

- Finished board thickness: 0.8mm, balancing durability and

compactness

- Finished Cu weight: 1oz (1.4 mils) outer layers, ensuring

efficient conduction

- Via plating thickness: 20 μm, enabling reliable interconnectivity

- Surface finish: Immersion Gold, for protection and improved

conductivity

- Top Silkscreen: White, facilitating component identification

- Bottom Silkscreen: None, for a clean and minimalistic appearance

- Top Solder Mask: Black, enhancing soldering and protection

- Bottom Solder Mask: None, for a simplified PCB design

- Each PCB undergoes a 100% electrical test prior to shipment,

ensuring quality and functionality

PCB Statistics:

- Components: 11, providing versatility for various applications

- Total Pads: 24, facilitating component connectivity

- Thru Hole Pads: 15, enabling secure connections

- Top SMT Pads: 9, supporting surface mount technology (SMT)

components

- Bottom SMT Pads: 0, indicating single-sided SMT assembly

- Vias: 7, allowing for efficient signal routing

- Nets: 2, ensuring proper connectivity

| PCB Material: | High-Tg and High Thermal Reliability Epoxy Resin |

| Designation: | TU-768 |

| Dielectric constant: | 4.3 |

| Layer count: | Double Layer, Multilayer, Hybrid PCB |

| Copper weight: | 0.5oz (17 µm), 1oz (35µm), 2oz (70µm), 3oz (105µm), 4oz (140µm), 5oz (175µm) |

| PCB thickness: | 10mil (0.254mm), 15mil (0.381mm), 20mil (0.508mm), 25mil(0.635mm), 30mil (0.762mm), 62mil(1.575mm) |

| PCB size: | ≤400mm X 500mm |

| Solder mask: | Green, Black, Matt Black, Blue, Matt Blue, Yellow, Red etc. |

| Surface finish: | Bare copper, HASL, ENIG, OSP, Immersion tin, Immersion Silver etc.. |

| Technology: | HDI, Via in pad, Impedance Control, Blind via/Buried via, Edge Plating, BGA, Countsunk Holes etc. |

Artwork Supplied:

This PCB artwork is provided in Gerber RS-274-X format, a widely

used industry standard for PCB manufacturing. This format ensures

compatibility and accuracy during the fabrication process.

Quality Standard and Availability:

The PCB adheres to the IPC-Class-2 quality standard, guaranteeing

high-quality manufacturing and reliability. It is available for

purchase worldwide, making it accessible to customers globally.

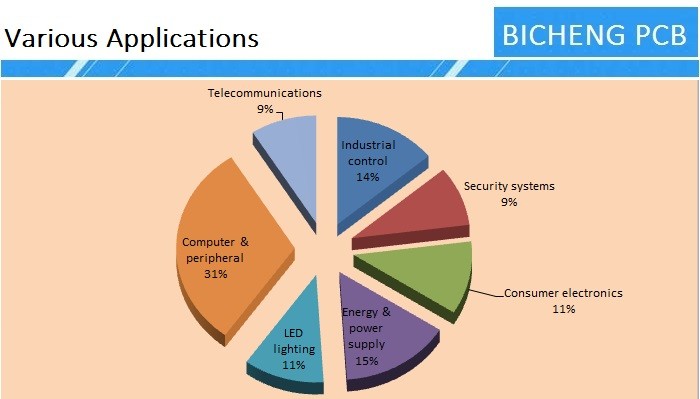

Typical Applications:

The TU-768 PCB is widely applicable in various fields, including:

- Consumer Electronics

- Servers and workstations

- Automotive industry

With its high-Tg and thermal reliability features, the TU-768 PCB is an excellent choice for demanding electronic applications that require exceptional performance and durability.