Taikang Yinyu Boiler Manufacturing Co., Ltd |

|

Top Heat Efficiency Non Pollution Fully Automatic Electric Heating Hot Water Boiler For Hospital

Part of product parameters

CWDR0.7-95/70

| NO; | Name | Unit | Number | Description |

| 1 | Rated efficiency | MW | 0.7 | |

| 2 | Water volume | M³ | 1.4 | |

| 3 | Rated outlet/inlet water temperature | ℃ | 95/70 | |

| 4 | Heating efficiency | % | 99 | |

| 5 | Output/inlet diameter | mm | DN100 | |

| 6 | Design fuels | / | Electric | |

| 7 | Blow down valve diameter | mm | DN100 | |

| 8 | Heating area(room) | ㎡ | 6000 | |

| 9 | Hot water output | M³/h | 18 | |

| 10 | Bulk size | mm | 2400×1200×1800 |

CWDR1.4-95/70

| NO; | Name | Unit | Number | Description |

| 1 | Rated efficiency | MW | 1.4 | |

| 2 | Water volume | M³ | 3.75 | |

| 3 | Rated outlet/inlet water temperature | ℃ | 95/70 | |

| 4 | Heating efficiency | % | 99 | |

| 5 | Output/inlet diameter | mm | DN125 | |

| 6 | Design fuels | / | Electric | |

| 7 | Blow down valve diameter | mm | DN125 | |

| 8 | Heating area(room) | ㎡ | 12500 | |

| 9 | Hot water output | M³/h | 36 | |

| 10 | Bulk size | mm | 2800×1700×2300 |

Hot water boiler without softening water will be what harm to the

boiler

1, waste of fuel

Boiler fouling, so that the heat ingressed surface heat transfer

performance is poor, fuel combustion heat can not be transferred to

the pot water in time, a large number of heat is taken away by

smoke, resulting in smoke temperature is too high, if the loss of

smoke increases, boiler thermal efficiency is reduced. In order to

maintain the boiler rating parameters, it must be added fuel, so

waste fuel. About 1 mm of scale waste disterated by 10% fuel.

2, damaged by heat ingress

The boiler with scale, due to poor heat transfer performance, the

heat of fuel combustion can not be quickly transferred to the pot

water, resulting in the temperature of the furnace and flue gas

increased. Therefore, the temperature difference between the two

sides of the heat ingle increases, the metal temperature increases,

the strength decreases, under the pressure of the pot, drum pack,

or even blasting.

3, reduce the boiler output

After boiler scaling, due to poor heat transfer performance, to

achieve the rated evaporation, we need to consume more fuel, but

with the thickness of the scale increase, the volume of the furnace

is certain, fuel consumption is limited.

4, corrosion

4.1, metal damage: water contains oxygen, acidic and alkaline

substances will produce corrosion on the metal surface of the

boiler, so that its wall thickness thinning, depression, and even

perforation, reducing the strength of the boiler, seriously

affecting the safe operation of the boiler.

4.2, produce scale corrosion: high-priced iron scale, easy to cause

contact with scale metal corrosion. And iron corrosion products and

easy to re-form scale. This is a vicious circle, it will quickly

lead to damage to boiler parts.

5, soda co-slinging

In addition to improper operation of soda co-growth, when the

furnace water contains more sodium chloride, sodium phosphate,

grease and silicate, or the organic matter and alkali action in the

pot water soaping, in the boiling and evaporation process of the

pot water, the liquid surface will produce foam, the formation of

soda co-steam.

6, destroy the water cycle

Boiler sub-natural circulation and forced e68a847a643333361303031

ring, all kinds of boiler water circulation is a certain balance,

whether it is up or down tube, must have enough cut-off area, when

the furnace pipe wall corrosion scale, it directly leads to the

reduction of the pipe cut-out area, water vapor resistance

increases, destroys the normal water cycle of the boiler so that

the temperature of the heat-resistant metal wall is increased.

Water circulation stop local furnace pipe due to the increase in

pipe temperature and produce local vaporization has occurred

burning or burst pipe accident, directly threatening the normal

operation of the boiler.

Pre-sale service:

We help customer choose the best boiler model according to

different requirements of various industry. Before delivery we

will provide foundation drawing, layout drawing, boiler room

layout, etc.

In-sale service:

We keep 24 hours online and keep close contacts during the

production process to ensure on time delivery with perfect

finished product.

After-sale service:

1. provide full range of original spare parts.

2. Engineers abroad installation and commissioning service is

available.

3. Our engineers will held a training for boiler workers to

ensure the safe operation.

4. Free maintenance and repair for one year and lifelong

service.

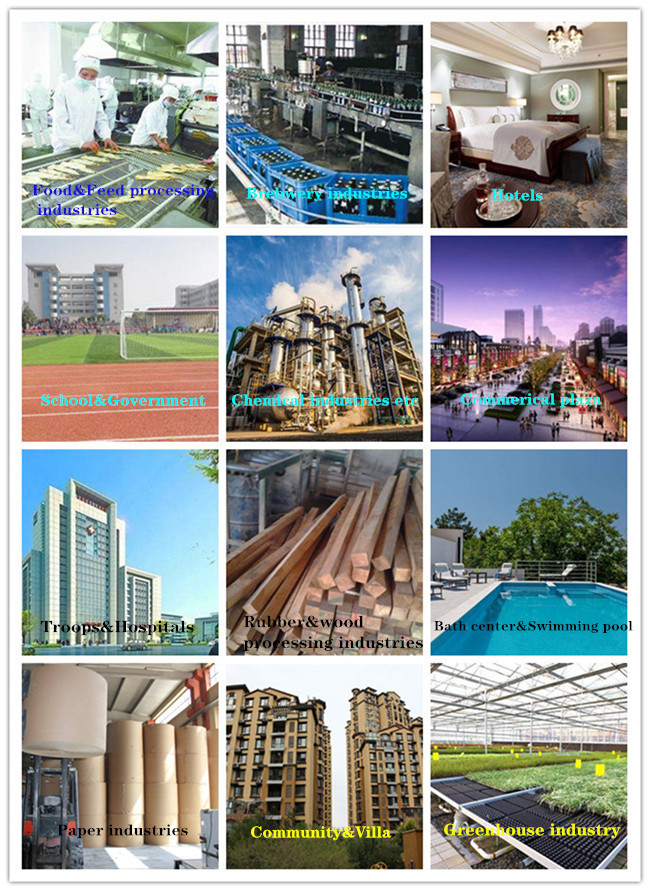

Boiler application areas