Shanghai Npack Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

Automatic 30ML 50ML Liquid Filling Machine For Cosmetic Oil

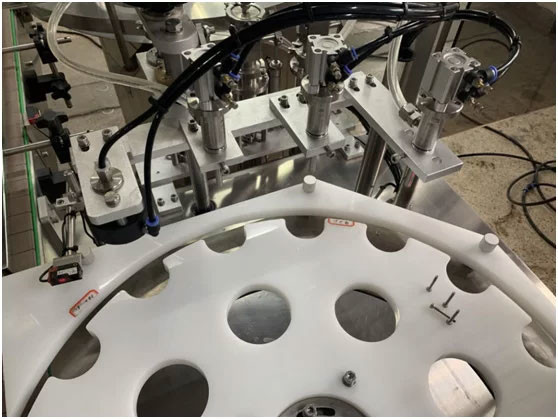

The cosmetic oil filling machine is intricately designed to facilitate the precise filling of small bottles ranging from 5-50ml, accommodating various shapes, including those with droppers, making it perfect for a wide spectrum of daily cosmetic oils such as liquid foundation, nail polish, perfume, and eye cream. This comprehensive solution incorporates a small bottle filling and capping machine, alongside a bottle unscrambler and labeling machine, to create a fully integrated bottling operation. It boasts a high-precision cam mechanism that ensures exact cap placement, enhanced by swift cam transmission for optimal capping head movement, ensuring uniform torsion and a mechanical pump for accurate dosing and filling. Operated via a user-friendly touch screen interface, this liquid filling machine ensures efficient processing by filling only when bottles are correctly positioned, thereby avoiding issues with uncapped or incorrectly capped bottles. Celebrated for its stable transmission, precise positioning, exact dosing, and user-friendly operation, this cosmetic oil filling machine stands as an indispensable tool for businesses specializing in cosmetic oil packaging.

1. The monoblock filling machine operates under PLC control, ensuring stable and reliable performance. It features a touch screen interface for straightforward human-machine interaction and ease of use.

2. The cosmetic oil filling machine is equipped with high-temperature and high-pressure resistant food-grade piping and quick-connect fittings for hassle-free disassembly and cleaning.

3. It includes a "no bottle, no fill" feature and a function for counting the number of fills, enhancing operational efficiency.

4. The machine is designed with a CIP (Clean-in-Place) function, streamlining the cleaning process.

5. It boasts high measurement precision, with a filling error rate of ≤ ±1%, ensuring consistent product quality.

6. Utilizes piston pump technology for filling, providing high accuracy in dispensing the product.

7. Constructed in compliance with the latest GMP (Good Manufacturing Practice) standards, reflecting a commitment to quality and safety in manufacturing.

|  |

|  |

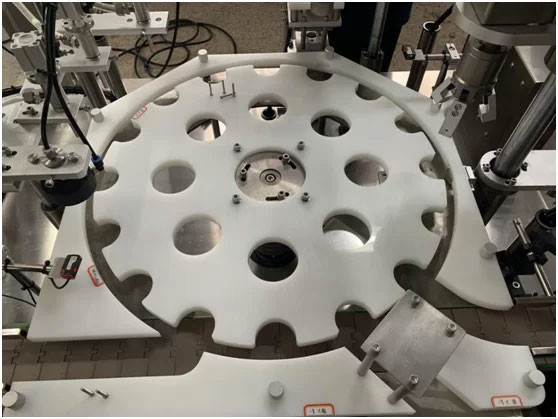

1. Bottle Unscrambling: Automatically organizes bottles in preparation for filling.

2. Automatic Bottle Advancement: Transports bottles to their specific processing station.

3. Precision Quantitative Filling: Accurately dispenses essential oil into bottles using an automated system.

4. Cap Management and Application: Automatically sorts, feeds, and fastens caps onto bottles with an efficient screwing mechanism.

5. Completed Product Conveyance: Moves finished products along a conveyor belt towards the next stage of handling or packaging.

1. Installation Service:

Our experienced technicians are on standby to install the filling machine at your premises. The service package includes installation fees, travel, meals, and related costs.

2. Training Program:

To ensure your small bottle filling machine operates at peak efficiency, we provide comprehensive training for distributors, operators, engineers, and technicians, either on-site or at our manufacturing facility.

3. Warranty Coverage:

Our repair services come with a one-year warranty, ensuring quality assurance, parts availability, and prompt assistance for any issues that may arise.

4. Consultation Service:

Leverage our no-cost consultation to find the perfect filling machine solution for your needs. Our expert sales team will assist you with tailored advice and provide CAD drawings of the machine setup.

5. Technical Support:

Enjoy access to our year-round technical support. Whether through email or phone, our team is ready to offer speedy responses to keep your operations running smoothly.

6. Spare Parts Provision:

A set of essential spare parts accompanies every shipment of our filling machine, ensuring you're prepared from the start, at no extra charge. For any additional needs, our inventory of high-quality spare parts is available for order anytime.