Shanghai Npack Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

Peristaltic Pump Automatic Factory 10ml 100ml Essential Oil Filling Machine

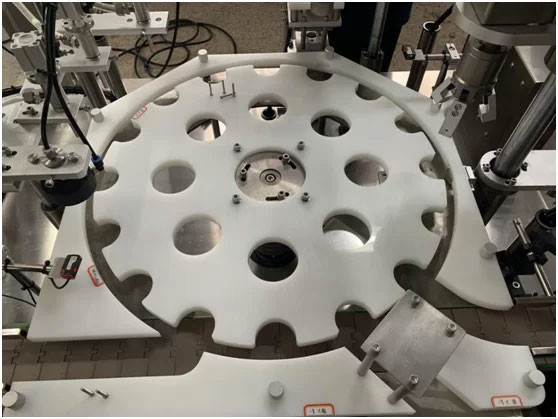

The automated essential oil filling apparatus finds extensive application in filling 5-50ml essential oil bottles with round or flat shapes, including dropper bottles. This bottling machine is designed for various daily cosmetic products like liquid foundation, nail polish, perfume, and eye cream. Key components of the system include a bottle unscrambler, essential oil filling capping machine, and labeling machine. A high-precision cam mechanism is incorporated, featuring a graduated dial for cap placement, accelerated cam transmission for capping head lifting, constant torsion capping, mechanical pump dosing and filling. The equipment is controlled via a user-friendly touch screen, ensuring no filling occurs without a bottle, and it prevents both uncapped and overcapped situations. With advantages such as stable transmission, precise positioning, accurate dosing, and convenient operation, this machine stands as an ideal tool for essential oil bottling companies.

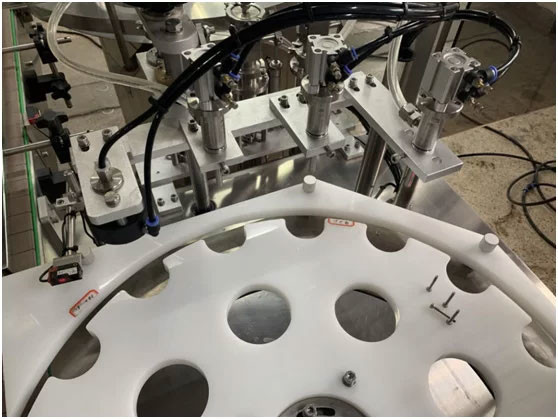

1. This equipment utilizes a conveyor belt with frequency conversion for bottle transport, employs stainless steel pump penetration for precise filling, incorporates automatic vibration cap sorting, and features pneumatic linear positioning for lower cap screwing (pressing). The filled and sealed products are automatically conveyed to the subsequent process by the conveyor belt.

2. The essential oil filling machine employs a peristaltic pump for accurate measurement, ensuring convenient operation and preventing dripping through the utilization of the suck-back function.

3. All electrical components in this system are sourced from reputable brands, ensuring ease of operation with a "no bottle, no filling" mechanism and highly accurate measurements.

4. Thanks to pneumatic control and mechanical positioning, this machine achieves high filling accuracy, keeping the error within 0.5 ‰.

5. The color touch screen interface facilitates user-friendly operation, supported by a PLC control system.

6. In addition to filling, this essential oil filling machine is capable of heating, stirring, and maintaining a constant temperature for both paste and liquid materials. It accommodates materials requiring specific heating, stirring, and temperature conditions to achieve the desired effect.

7. Equipped with a mechanical hand for screwing caps, the machine features an automatic sliding device to prevent cap damage.

8. The entire production line is compact, efficient, highly automated, leading to significant savings in labor costs.

9. Crafted from 304 stainless steel, the entire machine's shell is easy to clean and complies with GMP requirements.

Product Details

|  |

|  |

Committed to staying at the forefront of filling technology, we consistently invest in research and development to deliver the latest advancements. The Npack team is unwavering in its dedication to providing exceptional service and support throughout your association with us. Our reach extends globally, as we assist liquid processors and manufacturers in elevating their production capabilities.

2.Train:

For optimal performance of the filling machine, we offer on-site or factory training for dealers, machine operators, engineers, and technicians.

3.Guarantee:

When repairing the filling machine, expect efficient service, a one-year quality assurance period, parts supply, and swift feedback for troubleshooting.

4.Consulting Service:

Take advantage of our complimentary consultation service. Our professional sales team will guide you to the most suitable solution, complete with CAD drawing designs for the filling machine.

5.Technical Support:

Benefit from our all-weather, long-term technical support. Simply drop us an email or give us a call, and we'll provide quick feedback, ensuring you can be carefree.

6.Spare Part:

During transportation, we include a set of vulnerable spare parts for the filling machine at no additional cost. You can also order a comprehensive range of high-quality parts at any time.