Suzhou Beite Smart Instrument Co., Ltd |

|

Verified Suppliers

|

|

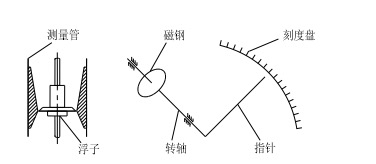

BTMF series micro-metal tube float flowmeter consists of the following parts:

1. Ontology

2. Measuring tube

3. Float

4. Header

5. Secondary coupling system

6. Electrical cables

Structure and principle

BTLZ series intelligent metal tube float flowmeter consists of two

Part composition:

1. Sensor -- Measuring tube and float;

2. signal transmitter ---- indicator;

There are four kinds of liquid connection materials for the sensor:

stainless steel and Hastelloy

Gold, titanium, stainless steel lining FEP; Users can vary

according to

Process pressure and corrosive medium requirements, choose

different contact liquid

Material to meet the needs of pressure resistance and media

anticorrosion of the process. According to different measurement

requirements, users can choose different types when selecting

Combination of indicators to achieve different measurement

requirements. The specific indicator form and its corresponding

function are shown in the indicator type chart.

The flow rate is measured by the transmitter in the indicator to

sense the change of float position through the coupling magnetic

steel to complete the flow indication and signal

Far out of the transmission. When the measured medium flows through

the measuring tube from bottom to bottom, the float is affected by

gravity, buoyancy and fluid velocity

When the three driving forces are balanced, the float is relatively

stationary at a certain position, which changes with the annular

gap area between the float and the cone and the fluid flow rate

The position of the float corresponds to the size of the measured

medium flow

Features

1. Strong all-metal structure design.

2. Suitable for gas and liquid measurement in various industries.

3. The new case structure design can be used in high temperature

environment without adding parts.

4. Specially designed cone measuring tube, wider measuring range,

better measuring linearity.

5. Can provide flange, clamp, thread and other process connection

methods, suitable for most factory application needs.

6. Measurement part of the material optional: stainless steel,

titanium, Hastelloy, PTFE, FEP and other materials.

7. The specially designed magnetic coupling system can

significantly improve the measurement accuracy and stability.

Specification

| Measuring range | Water (20℃) 16~150000 l/h | LCD | Instantaneous flow rate display value range : 0.000~99999 |

| Gas(0.1013MPa 20℃) 0.5~4000 m3/h | Cumulative flow display value range: 0.00~99999999 | ||

| Jacket pressure rating | 1.6MPa | Electrical Interface | M20×1.5,PG11,1/2”NPT Or user provides specifications |

| Medium temperature | Standard type -80℃~+220℃ | overall height | Standard type:250mm(For other installation methods, see the relevant table) |

| High temperature type | 300℃ | Protection level | IP65/IP67 |

| Lined FEP type | ≤85℃ | Explosion-proof signs | Intrinsically safe:ExiaIICT3~6 |

| Explosionproof type:ExdIICT4~6 | |||

| ambient temperature | -40℃~+120℃(C9≤85℃) (Remote transmission type with LCD display≤70℃) | Medium viscosity | DN15: ≤5mPa.s |

| ≤30mPa.s) | |||

| DN25: ≤250mPa.s | |||

| DN50~DN150:≤300mPa.s | |||

Range ratio | 10:1(Special type20:1) | output | Standard signal: two-wire system 4~20mA (can be equipped with HART communication) |

| Standard signal: three-wire system 0~10mA | |||

| Alarm signal: 1. Two relay outputs (limit value 125VAC/0.25A) | |||

| 2. One or two proximity switches (switch requirements are based on customer requirements) | |||

| Pulse signal output: 0-1KHz isolated output (output level Vpp>4.5V) | |||

| Accuracy level | 2.5(Special type1.5%or 1.0%) | powered by | Standard type: 24VDC±20% |

| AC type: 220VAC (85~265VAC) (need to be customized) | |||

| Battery type: 3.7@4.4-5.2AH lithium battery. According to different usage conditions, each group can be used (3 to 12 months), and the two groups can be used interchangeably. | |||

| work pressure | DN15~DN50 PN16MPa (Special type 25MPa) | Connection method | Standard type: HG20592 flange |

| DN80~DN150 PN10MPa (Special type 16MPa) | Special type: user provides flange standard | ||

| Threaded connection type: user specified |

How to use (installation)

There are 12 steps required to install the sanitary metal tube

rotameter.

1. Clean the welding slag and debris in the pipeline before

installing the flow meter;

2. The installation inclination of the upright part of the

calibration flowmeter perpendicular to the ground shall not exceed

5°. Otherwise, the measurement accuracy will be affected.

3. Position In order to ensure the measurement accuracy of the flow

meter, a straight pipe section of no less than 10xDN should be

added to the inlet end of the flow meter, and a straight pipe

section of no less than 5xDN should be added to the outlet end. The

regulating control valve should be installed at the flow meter

during measurement. downstream.

4. Model If the measured medium is a large pulsating flow or

two-phase flow, a buffer should be installed upstream of the flow

meter to reduce or weaken the pulsation to ensure that the flow of

the medium is single-phase stable. At the same time, it is

recommended to use a damping type flow meter. .

5. Measuring medium When the measuring medium is dirty or contains

magnetically conductive particles, it is recommended to install a

filter or magnetic filter upstream of the flow meter.

6. The installation of the support flow meter should be able to

properly support the vibration of the pipeline or reduce the axial

load of the flow meter. Otherwise, the support of the fixed flow

meter should be added.

7. Maintenance In order to facilitate the maintenance and repair of

the flow meter, the cleaning of the magnetic filter and the regular

maintenance of the user's pipelines, it is recommended to use the

bypass pipeline as shown in the figure.

8. Stability When the flow meter is used for gas measurement, it

should be ensured that the working pressure in the pipeline is not

less than 5 times the pressure loss of the flow meter, so that the

flow meter can operate stably and normally.

9. Before using the electric remote transmission and the flow meter

with alarm limit switch, open the instrument cover and connect the

wires correctly according to the wiring diagram.

10. According to the warning plate on the indicator of the meter,

take out the damping piece that prevents the float from vibrating

during transportation, and then use the meter after restoring it.

11. If the flow meter is turned on, because there is no pressure in

the pipeline or the system has not reached the normal working

pressure of the instrument, slowly open the control valve until the

system is normal before the instrument can be used. Otherwise, it

is easy to cause the pointer to jump or the float to suddenly move.

A rose damaged by impact.

12. User use: When the user uses it, if the density of the measured

fluid is different from that of water, or the parameters and

working status of the measured gas are different from the

manufacturer's regulations, the flow meter indication reading

should be converted. The conversion method is shown in the

appendix.

Precautions

Precautions when using the sanitary metal tube rotor flowmeter.

1. Metal rotor flowmeter, metal tube float flowmeter, and Verabar

flowmeter with high temperature resistance up to 450°C.

2. Suitable for measuring small diameter and low flow rate gas,

liquid and steam flow.

3. High-voltage resistant magnetic coupling principle, no leakage

and high pressure resistance.

4. Measure the flow rate. When the flow rate exceeds 100m3/h water

flow rate, the pressure loss will be large. .

5. The measuring range is mostly used for process control

instruments, with an accuracy of 1%, usually 1.5%, and a range

ratio of 10:1.

6. Suitable for occasions, including intrinsically safe

explosion-proof and explosion-proof types, suitable for dangerous

occasions.

7. Installation method The appropriate installation method is

vertical installation with bottom in and top out.

Manufacturer strength

Smart instrument direct supply manufacturer

The company has complete production and processing equipment. The

electronics workshop has a modern SMT assembly line and a complete

electronic design and development laboratory. The machinery

workshop has multiple precision CNC lathes, ordinary lathes,

processing, fully automatic circumferential seam welding machines,

drilling machines and other equipment. The calibration workshop has

two liquid calibration test lines and a small and medium flow gas

calibration test line to ensure that each product is tested

according to actual conditions. Calibration and verification to

ensure product quality.

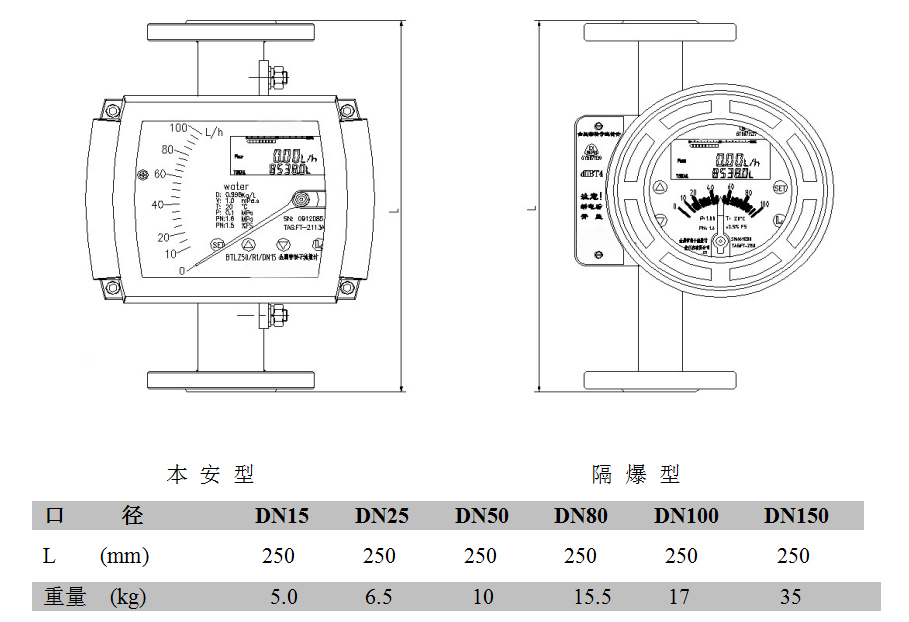

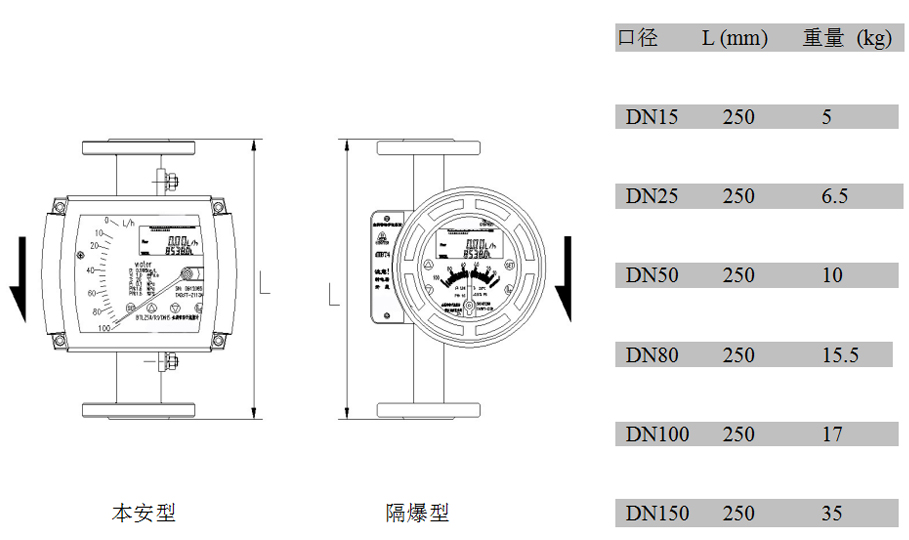

Standard dimensions and weight

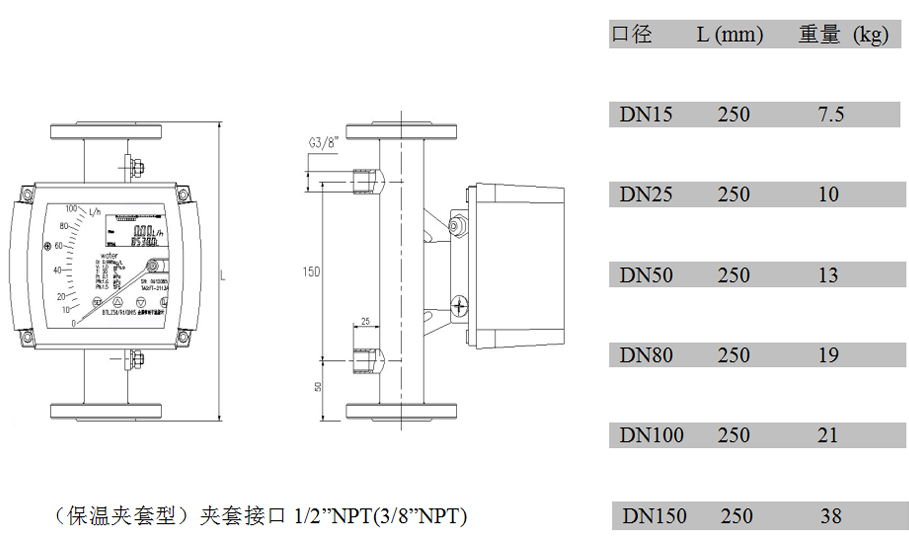

Jacket type overall dimensions and weight

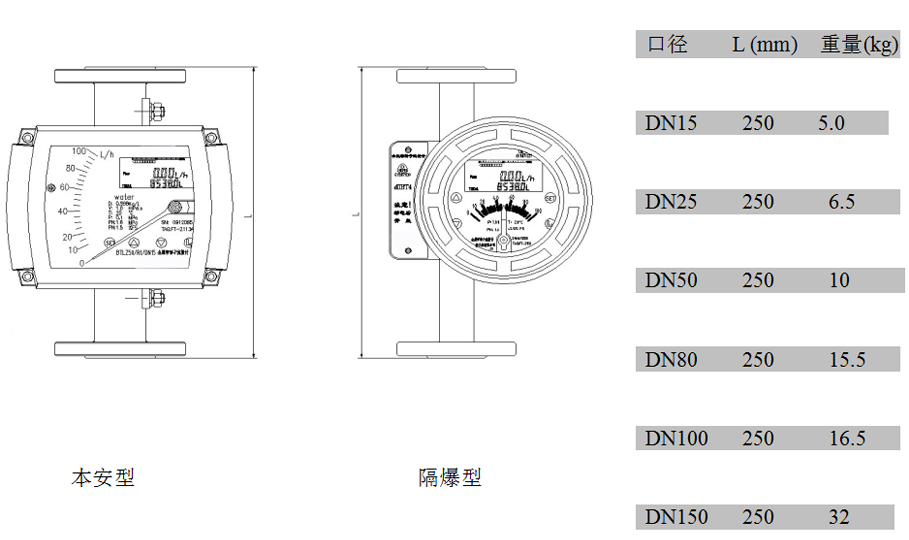

Lined FEP type overall dimensions and weight

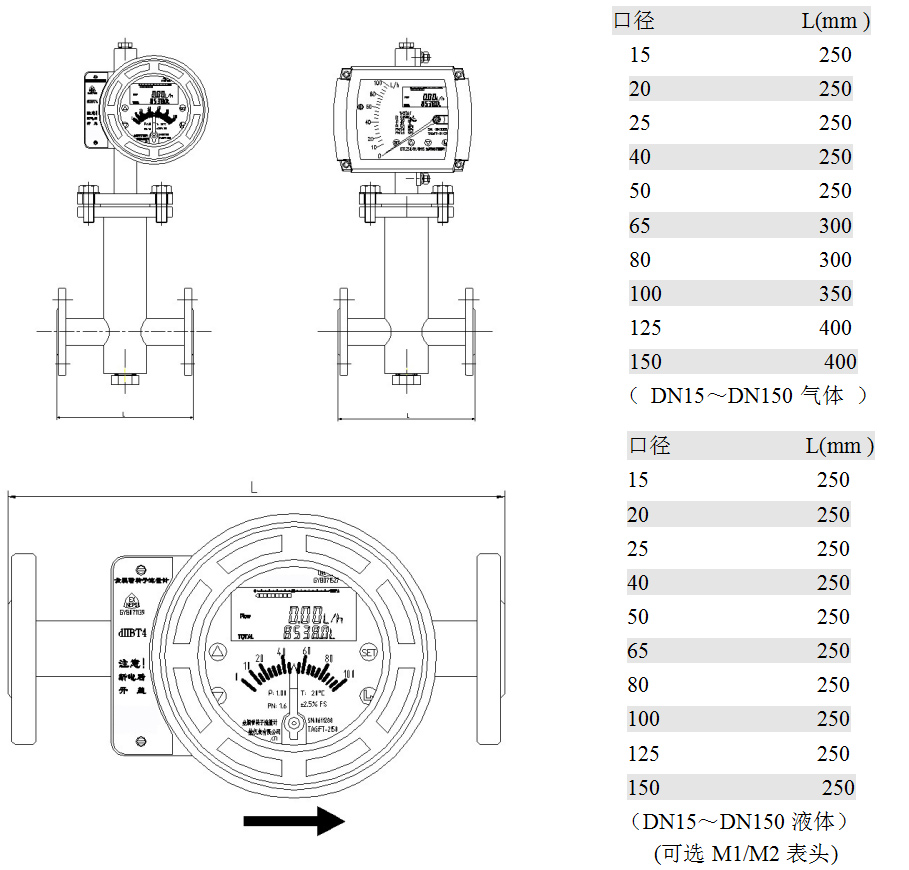

Dimensions and weight of top-in and bottom-out type

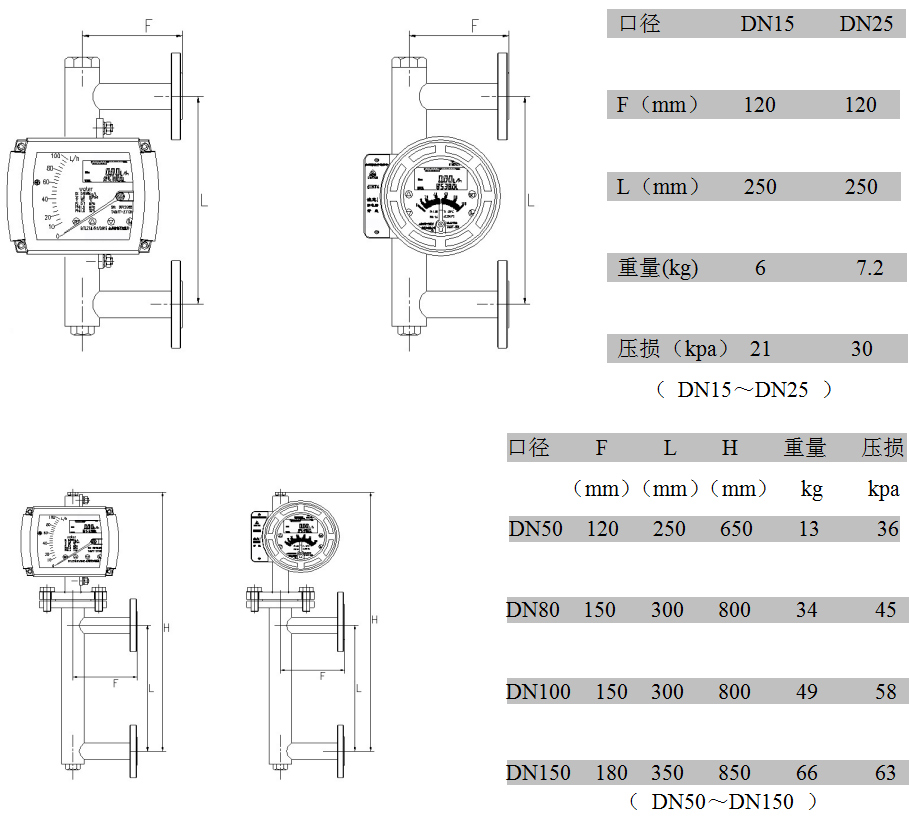

Side-in and side-out type: overall dimensions, weight and pressure loss

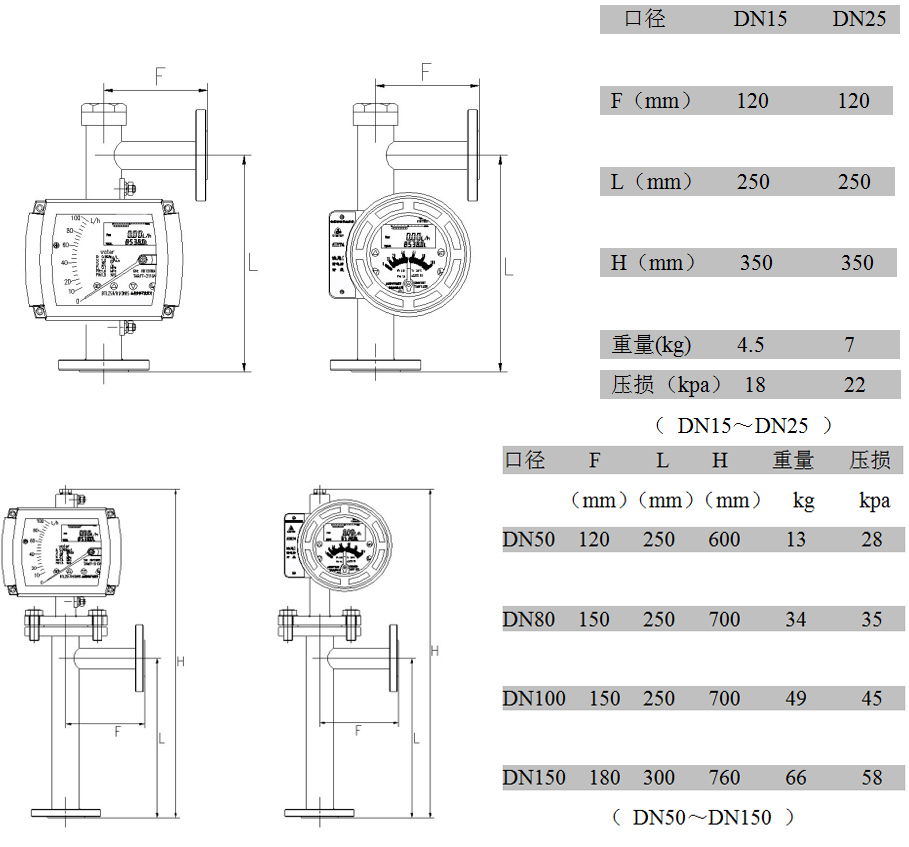

Bottom entry and side exit type: overall dimensions, weight and pressure loss

Horizontal installation type: overall dimensions, weight and pressure loss

FAQ

1. Q: What information need to be provided to choose the suitable

model?

A: Application field, Nominal pressure ,Medium & medium

temperture , Power supply , Output,

Flow range, Accuracy, Connection and other parameters.

2. Q: Are you a trade company or a manufacturer?

A: We are an ISO approved manufacturer specialized in level and

flow measuring instruments.

OEM & ODM service are available. Welcome to visit us in China.

3. Q: What is your MOQ?

A: To start our cooperation, sample order is acceptable.

4. Q: What is your delivery date for the Intelligent Mini Micro

Turbine Fuel Oil Diesel Flow Meter?

A: The delivery date is about 3-15 working days after receipt of

payment.

5. Q: What is your payment terms?

A: We support T/T, PayPal ,Western Union.

For mass production order, it is 30% deposit in advance and 70%

balance before shipment.

6. Q: Do you have a warranty for the Flow Meter?

A: Yes, we have the warranty of 12 months.