Suzhou Vanforge Metals Co., Ltd. |

|

52100 cold drawn bearing alloy steel round bar

52100 is a high carbon, chromium containing low alloy steel that is through hardening and noted in particular for use as bearings.

Applications

Principal applications are those for bearings in rotating machinery.

Machinability

Machinability of 52100 alloy is good by conventional methods. A spherodizing anneal at 1200 F before machining will improve the overall machinability of the alloy.

Forming

52100 may be formed by all conventional methods, including cold forging or stamping and hot or cold upset forming.

Welding

This is a high carbon alloy typically used in bearing applications where welding is not applicable or appropriate.

Heat Treatment

Heat treatment consists of heating to 1500 F followed by an oil quench for through hardening of the alloy. A normalizing heat treatment at 1600 F and slow cooling, to relieve machining stress, may be employed prior to the 1500 F and quench treatment.

Forging

The alloy may be supplied as forgings and also may be subsequently forged at 2200 F down to 1700 F

Hot Working

Hot working, such as upsetting, may be done in the range of 400 to 1000 F.

Cold Working

The alloy has good ductility and may be cold worked in the annealed or normalized conditions by conventional methods.

Annealing

Anneal at 1600 F and slow cool to relieve machining or cold working strains.

Aging

Not applicable to this alloy.

Tempering

Temper at 400 F.

Hardening

The alloy hardens from cold working or by heating and quenching - see "Heat Treatment". It also may be carburized at 1675 F and quenched after sufficient time for carburization. A second heating to 1450 F and second quench from that temperature should be used.

Bar size: dia. 40-150mm

Ordering Information

Orders for material under this specification should include the following information:

1 Quantity,

2 Grade identification,

3 Specification designation and year of issue,

4 Dimensions, and

5 Supplementary requirements, if included.

Grain Size

The steels covered by this specification shall have the capability of showing a fine fracture grain size (approximately ASTM No. 8 in accordance with Test Methods E112) when quenched from normal austenitizing temperatures not exceeding 1550°F [840°C].

Decarburization and Surface Imperfections

Decarburization and surface imperfections shall not exceed the limits specified in Tables 4 and 5. Decarburization shall be measured using the microscopical methods described in Test Methods E1077.

Microstructure

When annealing is specified in the order, the structure shall be rated and reported in accordance with Guide A892 as follows:

Carbide Size (CS)—As the appropriate carbide size is dependent on application, the limits shall be as agreed upon between manufacturer and purchaser.

Carbide Network (CN)—As the network is influenced by section size, the limits shall be as agreed upon between manufacturer and purchaser.

Lamellar Content (LC)—52100 steels shall have a lamellar content not to exceed LC1. Lamellar content of other compositions shall be as agreed upon between manufacturer and purchaser.

The material shall be free from excessive carbide segregation.

Hardness

When annealing is specified in the order, the steel shall have a completely spheroidized microstructure and a hardness as specified in Table as below.

| Product | Condition | Hardness, Brinell, max. |

| Bars | Hot rolled, annealed | 207 |

| bars | Annealed, cold drawn | 248 |

Small sizes where Rockwell B scale hardness readings are impractical shall have a maximum tensile strength of 110 000 psi [760 MPa].

Hardness and tensile tests shall be in accordance with test methods described in Test Methods and Definitions A370.

Product size range

Diameter: 40mm - 150mm

Length: on request

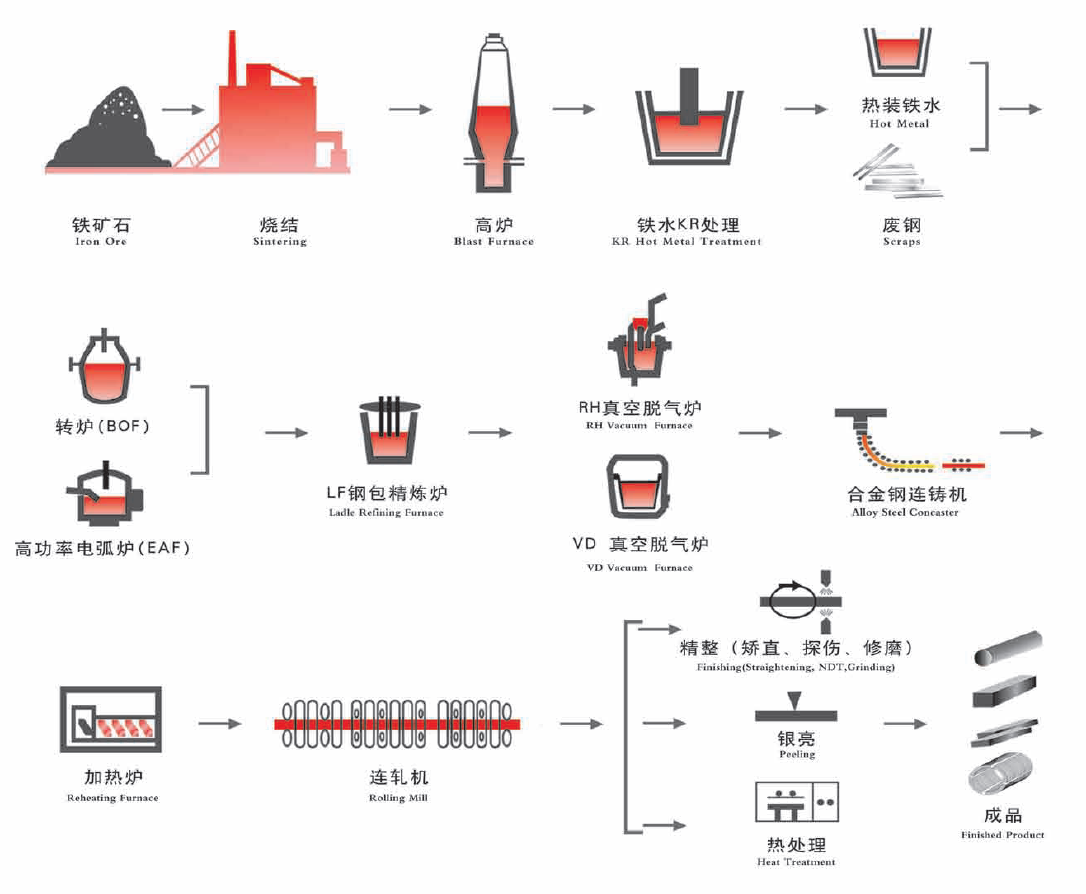

Production Process

Key clients