Quanzhou Yuanyuan Cloud Technology Co., Ltd. |

|

Verified Suppliers

|

|

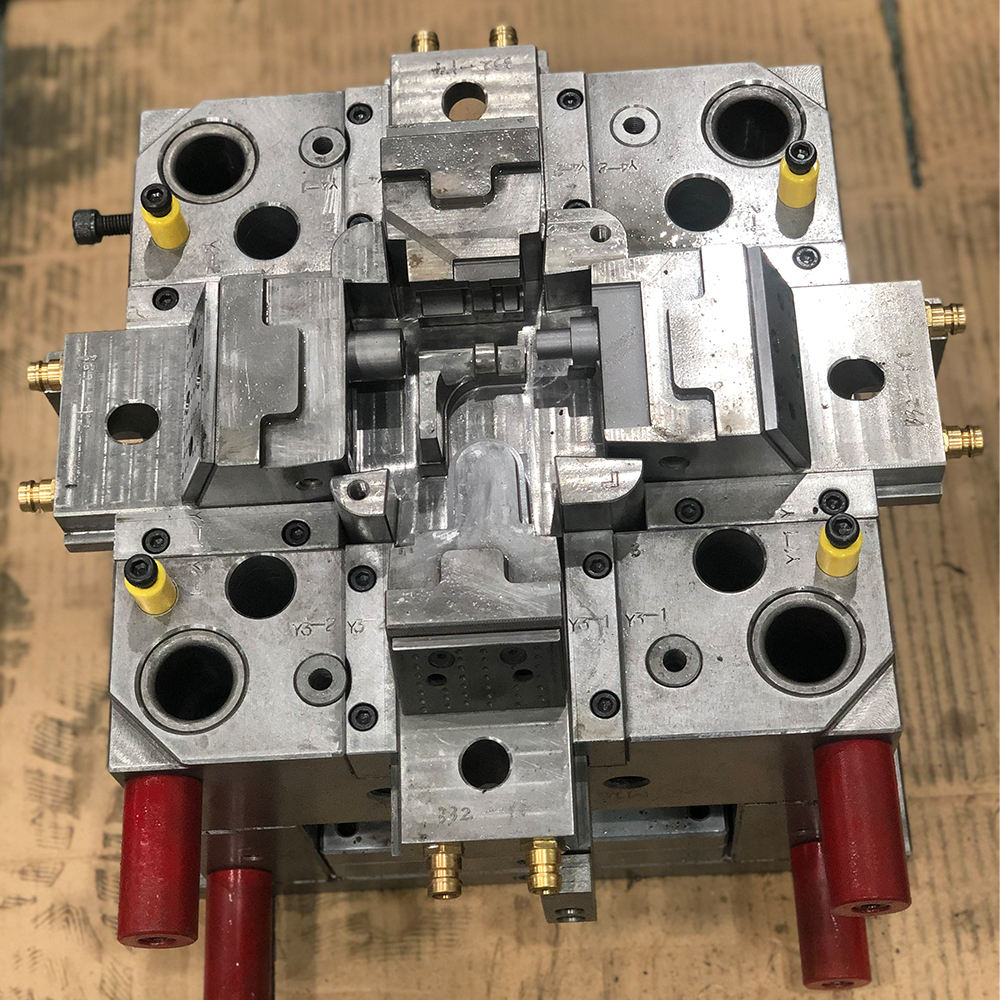

High Design Flexibility Mold Development High Precision Efficiency for Your Requirements Mold development

In the realm of industrial manufacturing, the development of precision moulds stands as a pivotal process that significantly impacts the efficiency, cost, and quality of production. Our Mold Development product is designed to cater to businesses seeking to enhance their production capabilities with speed, precision, and cost-effectiveness. Crafted with a strict quality control system, our moulds ensure that each unit produced meets the highest standards of excellence, a testament to the meticulous engineering and manufacturing processes that are a hallmark of our brand.

At the forefront of our Mold Development product is the promise of speed. Understanding the critical nature of time in market competitiveness, we have honed our processes to deliver fast turnaround times without compromising on quality. Our state-of-the-art facilities in China are equipped with the latest technology in mould manufacturing, enabling us to cut down production times and respond promptly to the dynamic needs of our clients. This expedited process allows businesses to accelerate their product development cycle and achieve faster time-to-market for their offerings.

Quality is the cornerstone of our operations, and our Mold Development product is no exception. Every mould undergoes stringent quality control procedures to ensure that it meets our rigorous standards. Our team of skilled professionals in China meticulously oversees each stage of the mould-making process, from design to final inspection. This strict quality control ensures that each mould produced is free of defects and capable of producing high-quality parts consistently, reinforcing our commitment to excellence.

While quality and speed are critical, we understand that cost is a pivotal factor for many businesses. Our Mold Development product is designed to be cost-effective, providing an optimal balance between price and performance. By optimizing our manufacturing processes and leveraging the efficiencies inherent in China's industrial ecosystem, we can offer moulds at competitive prices without sacrificing quality or precision. This cost-effectiveness ensures that businesses of all sizes can access top-tier moulding solutions without incurring prohibitive expenses.

Precision is paramount in the world of moulds, and our product delivers high precision to ensure that the final parts produced are accurate to the original design specifications. Utilizing advanced CNC machining and other precision engineering technologies, our moulds are crafted with tight tolerances and exacting dimensions. This high level of precision minimizes waste and reduces the need for post-production finishing, ultimately leading to more efficient production processes and better overall product quality.

Our Mold Development product boasts wide compatibility with a range of materials, making it a versatile solution for various industries. Whether it is plastics, metals, or composite materials, our moulds are engineered to handle the specific requirements of each substrate. This compatibility with a broad spectrum of materials opens up a myriad of possibilities for product design and innovation, enabling businesses to explore new markets and applications with confidence.

In summary, our Mold Development product represents the pinnacle of mould manufacturing, combining fast production speeds, strict quality control, cost-effectiveness, high precision, and wide material compatibility. As a leader in the mould industry in China, we are committed to providing our clients with solutions that not only meet but exceed their expectations. Our dedication to perfection in every aspect of our product ensures that businesses partnering with us are well-equipped to succeed in the competitive global marketplace.

| Attribute | Description |

|---|---|

| Quality Control | Strict |

| Precision | High |

| Maintenance | Low |

| Customization Options | Available |

| Efficiency | High |

| Size | Customizable |

| Speed | Fast |

| Durability | High |

| Application | Industrial Manufacturing |

| Design Flexibility | High |

The Mold development product with Model Number 001, originating from China, is a quintessential tool in industrial manufacturing, reflecting an amalgamation of design flexibility, efficiency, and durability. This mold is ISO certified, ensuring its conformation to international standards, and ready for deployment in a variety of application occasions and scenarios.

With a Minimum Order Quantity of 100 and an approachable price point of 1, this mold is an economical option for businesses looking to scale their production. The Neutral Packing packaging details ensure that the product arrives in pristine condition, while the 30-day delivery time frame demonstrates a commitment to prompt service. The Payment Terms, which accept TT, provide a convenient transactional method for clients, and the substantial Supply Ability of over 10000 pieces every 7 days underscores the capability to meet high demand volumes.

The Compatibility of the 001 mold with a Wide Range Of Materials makes it a versatile asset in various manufacturing environments. Whether dealing with plastics, metals, ceramics, or composites, this mold is designed to handle diverse materials with ease, ensuring that it can be applied to a multitude of mold development projects.

The Application of the 001 mold spans across Industrial Manufacturing sectors such as automotive, aerospace, consumer goods, and medical devices. Its High Design Flexibility allows for the creation of complex geometries and intricate designs that are essential in today's innovative market. The High Efficiency of the mold ensures that production cycles are swift, reducing downtime and increasing output rates. Furthermore, the High Durability of the product guarantees a long service life, reducing the need for frequent replacements and thus, cutting down on costs and waste.

In conclusion, the Mold development product model 001 is an indispensable tool for manufacturers seeking to boost their production capabilities. Its universal design, paired with robust construction and high performance, makes it a reliable and cost-effective solution for businesses aiming to excel in mold development and achieve excellence in their respective industries.

Model Number: 001

Place of Origin: China

Certification: ISO

Minimum Order Quantity: 100

Price: Negotiable

Packaging Details: Neutral Packing

Delivery Time: 30 days

Payment Terms: TT

Supply Ability: 10000+ pcs/month

Material: Plastic

Compatibility: Wide Range Of Materials

Cost: Cost-effective

Precision: High

Efficiency: High

Our Plastic Injection Mould services cater to a diverse range of customer requirements. Manufactured in China, our molds boast an ISO certification, ensuring high-quality standards in every product. Suitable for a wide range of materials, we guarantee a cost-effective and highly efficient mold development experience with precision engineering at the forefront. Trust China's expertise for all your plastic injection moulding needs.

Our Mold Development Product comes with comprehensive technical support and services designed to ensure that you can use our product effectively and efficiently. Our support includes access to a suite of online resources, including detailed documentation, FAQs, and troubleshooting guides that cover common issues and their resolutions. We provide regular updates and patches to enhance functionality and address any emerging technical matters.

In addition to online resources, we offer dedicated support through our team of experienced technical specialists who can assist with more complex or product-specific concerns. Our professional services include personalized consultations to optimize your mold design and production processes, as well as training sessions to help your team get the most out of our product.

To maintain the highest level of performance and reliability, we also offer maintenance services for our Mold Development Product. This includes regular check-ups, performance tuning, and preventive measures to ensure your mold development continues without interruption. We are committed to providing you with the support and services you need to achieve excellence in your molding projects.

Product Packaging:

All mold development products are securely packaged in high-quality, durable materials designed to protect the contents during transit. Each mold is encased in a protective foam insert, tailored to its unique contours, ensuring a snug fit and preventing movement inside the box. The outer packaging is a sturdy, corrugated cardboard box that is sealed with heavy-duty packing tape. A detailed packing list is included inside the box, along with care instructions to maintain the integrity of the mold.

Shipping:

We ship our mold development products worldwide using trusted courier services to ensure timely and safe delivery. Upon dispatch, customers will receive a tracking number to monitor their shipment's progress. Our products are typically shipped within 2-3 business days after order confirmation. Shipping times may vary depending on the destination but are generally between 5-10 business days. Please note that any customs fees or import duties are the responsibility of the recipient. We take every precaution to ensure that your product arrives in perfect condition and is ready for immediate use.

Q1: What is the model number of the mold development product?

A1: The model number of the mold development product is 001.

Q2: Where is the mold development product manufactured?

A2: The mold development product is manufactured in China.

Q3: Does the mold development product have any certifications?

A3: Yes, the mold development product is certified by ISO.

Q4: What is the minimum order quantity for the mold development product?

A4: The minimum order quantity for the mold development product is 100 units.

Q5: How is the mold development product packaged?

A5: The mold development product is packaged in neutral packing to ensure safety during transportation.

Q6: What is the price of the mold development product?

A6: The price of the mold development product is set at 1 unit of your local currency.

Q7: What is the delivery time for the mold development product?

A7: The delivery time for the mold development product is approximately 30 days after order confirmation.

Q8: What are the payment terms for purchasing the mold development product?

A8: The payment terms for purchasing the mold development product are TT (Telegraphic Transfer).

Q9: What is the supply ability of the mold development product?

A9: The supply ability of the mold development product is over 10,000 pieces every 7 days.