Quanzhou Yuanyuan Cloud Technology Co., Ltd. |

|

Verified Suppliers

|

|

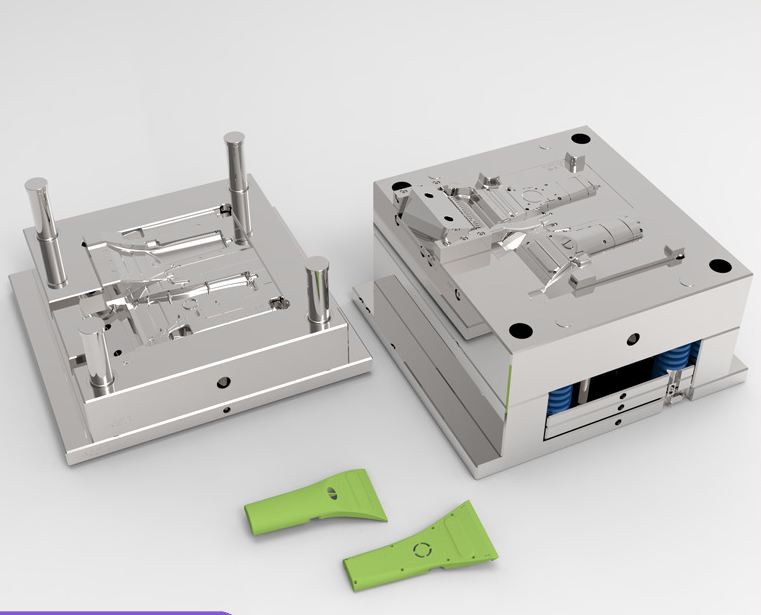

Precision injection mold plastic injection mold / aluminum mould making china manufacturer plastic mould die maker

The advent of modern industrial manufacturing has brought about an era where precision, efficiency, and durability are not just desired but required for any successful operation. Our Mold Development Product is at the forefront of this industrial revolution, particularly within the realm of plastic injection molding. Manufactured in China, a hub for high-quality industrial advancements, our product is specifically designed to meet the rigorous demands of today's fast-paced production environments.

Our Mold Development Product stands out due to its customizable size. Recognizing that no one-size-fits-all solution exists in the industrial sector, we provide our clients with the flexibility to tailor the mold to their specific needs. Whether the requirement is for small intricate components or large robust parts, our molds are designed to be scalable and adaptable, ensuring that they fit seamlessly into any manufacturing process.

When it comes to application, our product is versatile and can be utilized across various sectors within industrial manufacturing. This product is particularly adept at serving the plastic injection mould industry where precise and robust mold development is crucial. The molds are engineered to handle a wide range of plastic materials and are capable of producing complex shapes with fine details, making them the perfect tool for manufacturers who require high-quality plastic parts.

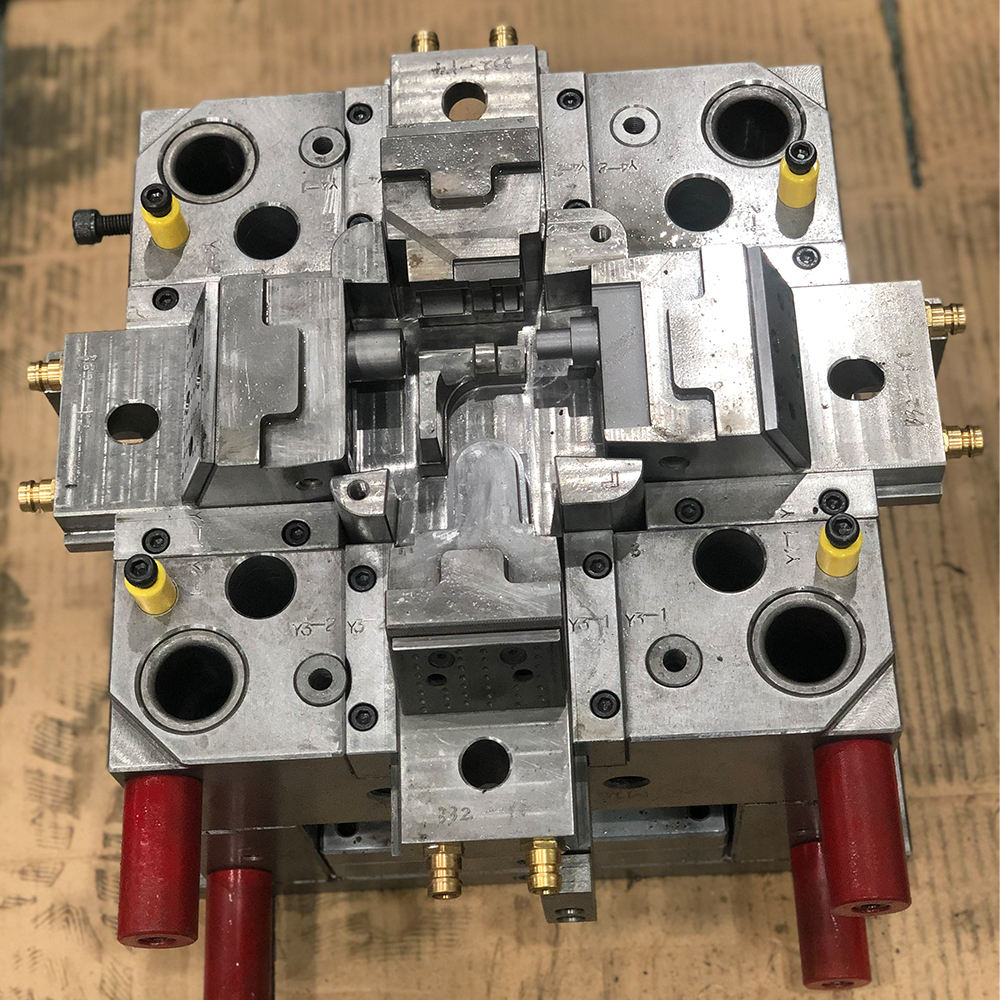

Maintenance of our molds is designed to be as low as possible. We understand that time spent on maintenance is time not spent on production, which is why our molds are manufactured using high-grade materials and advanced techniques to ensure that they withstand the test of time with minimal upkeep. Our customers can expect a product that operates at peak performance with infrequent maintenance interventions, thereby maximizing production uptime.

Efficiency is another cornerstone of our Mold Development Product. In the high-stakes world of industrial manufacturing, every second counts, and our molds are engineered to reduce cycle times. The high-efficiency design ensures that the molding process is streamlined, leading to faster production rates without compromising on the quality of the end product. This means that manufacturers can achieve higher output, meet deadlines more comfortably, and maintain a competitive edge in the market.

The durability of our Mold Development Product is also of paramount importance. Constructed with robust materials that are resistant to wear and tear, these molds can withstand the rigors of continuous use in harsh industrial environments. The high durability translates into a longer lifespan for the mold, providing an excellent return on investment as the need for replacements is greatly reduced. This durability also ensures that the molds maintain their precision over time, thus ensuring consistent product quality.

Our Mold Development Product is a testament to the innovation and quality that has become synonymous with China's industrial manufacturing prowess. As a leader in the plastic injection mould industry, we are committed to providing our clients with molds that are not just tools but a vital component of their success. With a focus on customizable size, application versatility, low maintenance, high efficiency, and durability, our molds are designed to elevate your manufacturing capabilities to the next level.

| Attribute | Details |

|---|---|

| Customization Options | Available |

| Application | Industrial Manufacturing |

| Precision | High |

| Cost | Cost-effective |

| Compatibility | Wide Range Of Materials |

| Speed | Fast |

| Design Flexibility | High |

| Efficiency | High |

| Quality Control | Strict |

| Size | Customizable |

The Model Number 001 mold development product, with its genesis rooted in China, is a stellar example of the craftsmanship and precision that the region's manufacturing sector is renowned for. This product comes with a robust ISO certification, ensuring that it meets international standards for quality and reliability. Designed with the needs of various industries in mind, this mold development tool boasts a wide array of applications and scenarios.

Whether for small-scale boutique operations or large industrial projects, the Model Number 001 is the selected product among discerning manufacturers. The Minimum Order Quantity is set at 100, making it accessible for businesses of varying sizes. Furthermore, the cost is incredibly competitive, with a price point of 1, catering to budget-conscious clients without compromising on quality. Packaging details are meticulously addressed, with a Neutral Packing that guarantees the product's integrity upon delivery.

The delivery time for this selected product is approximately 30 days, a testament to the efficiency and speed of the supply chain. Payment is streamlined through TT (Telegraphic Transfer), ensuring a smooth transaction process. With a formidable supply ability of over 10,000 pieces every 7 days, the Model Number 001 stands ready to meet the demands of a rapidly moving market.

Maintenance is another area where Model Number 001 shines, as it requires low upkeep, allowing businesses to focus on productivity rather than maintenance. Customization options are readily available, ensuring that the product can be tailored to the specific needs and requirements of any operation. This level of customization, coupled with the product's compatibility with a wide range of materials, makes it a versatile solution for numerous applications.

The design flexibility of the Model Number 001 is high, which is critical for businesses looking to innovate and adapt in dynamic market conditions. Moreover, the speed of production when using this mold development product is fast, enabling swift turnaround times and the ability to meet tight deadlines. In conclusion, the Model Number 001 from China represents a selected product that delivers excellence in mold development, with a range of attributes and benefits that make it indispensable for modern manufacturing.

Model Number: 001

Place of Origin: China

Certification: ISO

Minimum Order Quantity: 100

Price: 1

Packaging Details: Neutral Packing

Delivery Time: 30

Payment Terms: TT

Supply Ability: 10000+pc+7

Compatibility: Wide Range Of Materials

Material: Plastic

Design Flexibility: High

Application: Industrial Manufacturing

Customization Options: Available

Our selected products, including the Plastic Injection Mould for Mold development, are designed to meet the highest standards of quality and performance. With a model number of 001 and origins in China, each mold comes with ISO certification to ensure reliability and excellence in industrial manufacturing applications. With a minimum order quantity of 100 and a competitive price, our molds are presented in neutral packing with a delivery time of 30 days. Payment is facilitated via TT, and we boast a supply ability of 10000+pc+7, ensuring we can meet your demands promptly. Our molds are compatible with a wide range of materials, made from high-quality plastic, and offer high design flexibility. Customization options are also available to tailor the Plastic Injection Mould to your specific Mold development needs.

Our Mold Development Product comes with comprehensive technical support and services to ensure the best experience for our customers. Our dedicated team of experts is available to provide guidance on product features, usage, and troubleshooting to help you optimize your mold design and manufacturing processes. We offer a range of support services including:

- Detailed product documentation: Access our extensive library of user manuals, technical specifications, and setup guides to help you get started with your Mold Development Product.

- Online resources: Visit our website for a wealth of information, including FAQs, how-to articles, video tutorials, and best practices for mold development.

- Software updates: Keep your product up-to-date with the latest features and improvements by downloading the most recent software updates from our support portal.

- Community forums: Join the discussion with other mold development professionals in our community forums. Share your experiences, ask questions, and get advice from peers and our support team.

- Training and workshops: Enhance your skills and knowledge by enrolling in our training programs and workshops, designed to cover various aspects of mold development and product utilization.

Please note that our technical support services do not include on-site assistance. However, we are committed to providing you with the necessary tools and information to address any issues remotely. For any further assistance or inquiries, please refer to our customer service section (contact information excluded).

Thank you for choosing our Mold Development Product. We ensure that every item is packaged with the utmost care to guarantee its safe arrival. Our product is encased in high-quality, durable materials designed to protect it from any damage during transit. For shipping, we use trusted carriers to provide efficient and reliable delivery, so you can start your mold development projects without delay. Please inspect the package upon arrival and contact us immediately if any issues arise. Your satisfaction is our top priority.

Q1: What is the model number of the mold development product?

A1: The model number of the mold development product is 001.

Q2: Where is this mold development product made?

A2: This product is made in China.

Q3: Does the mold development product have any certifications?

A3: Yes, the product is ISO certified.

Q4: What is the minimum order quantity for the mold development product?

A4: The minimum order quantity for this product is 100 units.

Q5: How is the mold development product packaged?

A5: The product is packaged using Neutral Packing details for safe transportation.

Q6: What is the price of each unit of the mold development product?

A6: The price per unit is $1.

Q7: What is the estimated delivery time for the mold development product?

A7: The estimated delivery time is 30 days after order confirmation.

Q8: What are the payment terms for purchasing this mold development product?

A8: The payment terms are TT (Telegraphic Transfer).

Q9: What is the supply ability of the mold development product?

A9: The supply ability is over 10,000 pieces every 7 days.