Quanzhou Yuanyuan Cloud Technology Co., Ltd. |

|

Verified Suppliers

|

|

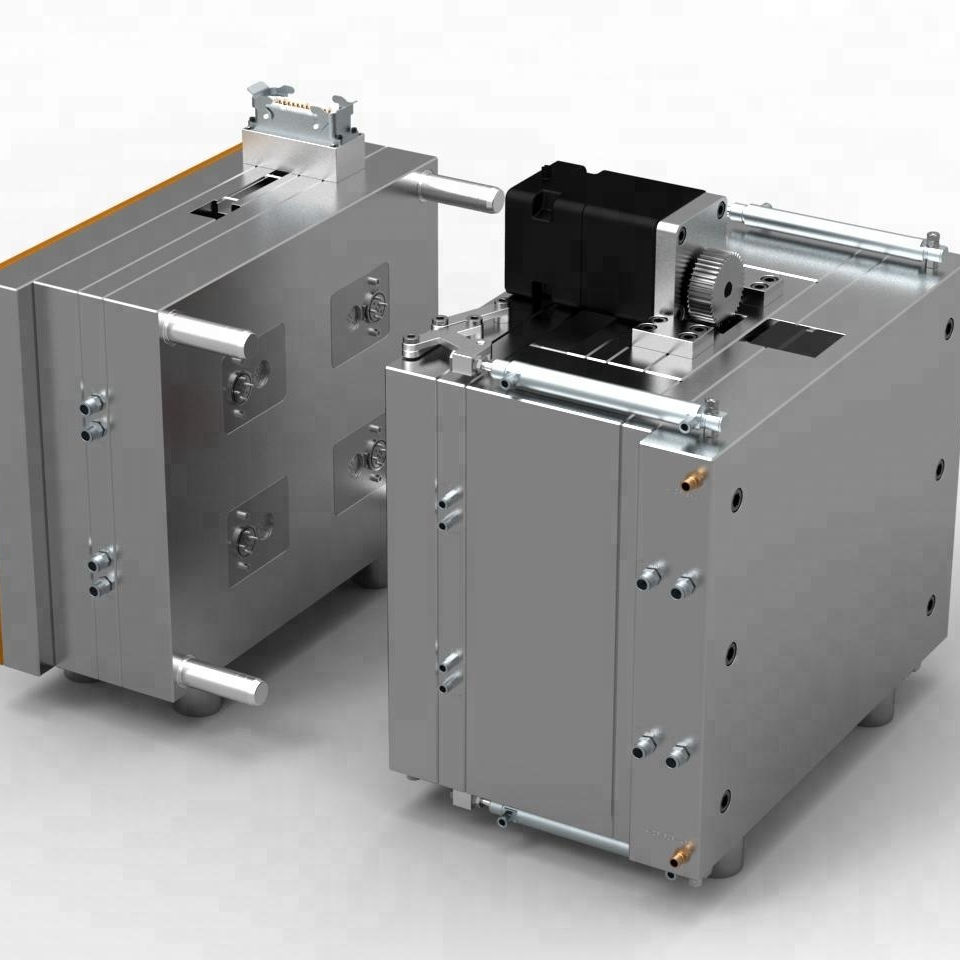

TPU material two shot plastic injection overmolded product plastic injection mold factory custom Mold manufacturer Mold

The advent of precision engineering has revolutionized the way industries approach manufacturing, particularly in the realm of plastic injection molding. Our state-of-the-art mold design product harnesses this innovation, providing a solution tailored to the needs of businesses looking to create high-quality plastic injection mold parts. Developed with the intricacies of custom mold parts in mind, this product stands as a testament to the fusion of advanced technology and industrial expertise.

At the core of our mold design product is the utilization of sophisticated Computer-Aided Design (CAD) software. This powerful tool enables our team to craft intricate and precise designs that meet the exact specifications of our clients. The CAD software not only ensures accuracy but also allows for a high degree of customization, making it possible to create custom mold parts that cater to unique applications and requirements. The precision afforded by our CAD technology is underscored by a remarkable tolerance of 0.01mm, ensuring that each mold produced is of the utmost quality and fits seamlessly within the intended assembly.

The material selection for our mold design product is equally as important as the design process itself. We employ premium-grade steel in the construction of our molds, prized for its durability and longevity. Steel's robustness makes it the ideal choice for molds that are intended for long-term use and high-volume production runs. Moreover, steel's capacity to withstand the high pressures and temperatures associated with plastic injection molding means that our molds maintain their integrity and dimensional accuracy over time, ensuring consistent production of plastic injection mold parts.

We recognize that time is of the essence in the fast-paced industrial world, which is why we offer a competitive lead time of 2-4 weeks. This expedited timeframe ensures that our clients can progress from design to production without significant delays, providing them with a significant edge in the market. Our team works diligently to ensure that each mold is designed, fabricated, and delivered within this window, all while maintaining the highest standards of quality and precision.

Our mold design product is versatile and scalable, catering to both small and large-scale production volumes. Whether a client requires a limited run of custom mold parts for specialized equipment or mass production of plastic injection mold parts for widespread distribution, our molds are engineered to perform consistently across varying volumes. This scalability is a key feature, ensuring that our clients can ramp up their production as demand grows without the need for additional investment in new molds.

In conclusion, our mold design product stands as a paragon of industrial craftsmanship. It embodies the convergence of advanced CAD technology, stringent tolerance standards, robust material selection, and flexible production volume capabilities. This product is a pivotal asset for any business seeking to produce high-quality plastic injection mold parts with efficiency and precision. We take pride in our ability to deliver custom mold parts that not only meet but exceed the expectations of our clients in both performance and reliability, cementing our reputation as a leader in the mold design industry.

| Parameter | Specification |

|---|---|

| Lead Time | 2-4 Weeks |

| Quality Control | Strict Inspection And Testing |

| Mold Size | Customized |

| Plastic Molding Type | Injection |

| Production Volume | Small To Large Scale |

| Design Software | CAD |

| Application | Manufacturing |

| Product Type | Industrial Design |

| Mold Life | 100,000-1,000,000 Shots |

| Tolerance | 0.01mm |

The art of precision in manufacturing custom mold parts is a critical aspect in a range of industries, where the demand for high-quality, intricately designed components is essential. Originating from China, a hub of manufacturing excellence, our mold design product stands out with an ISO certification that ensures adherence to international standards. Tailored to meet various application occasions and scenarios, our custom mold parts serve a multitude of purposes.

Our Plastic injection mold parts are particularly favored in the automotive, aerospace, medical, and consumer electronics sectors. These industries demand not just precision but also the reliability that comes with our mold parts. Considering the minimum order quantity of 100 pieces, our products are an excellent choice for medium to large-scale production runs. Priced competitively at 1 unit per price, we offer exceptional value for the level of craftsmanship involved.

Packaging details are a testament to our commitment to quality, with neutral packing that ensures the safety and integrity of each component during transit. Our delivery time is set at 30 days, striking a balance between meticulous production and timely supply. Payment terms are straightforward with TT (Telegraphic Transfer), providing a secure and efficient transaction process. With a robust supply ability of over 10000 pieces every 7 days, we can cater to both regular demands and bulk orders with ease.

The mold cost varies depending on the complexity of the design, allowing for customization that fits specific requirements while maintaining a high standard of surface finish through polishing. This customization extends to the rigorous quality control, where strict inspection and testing are the norms, ensuring that every part meets the stringent criteria that our customers expect. The tolerance of 0.01mm further speaks to the precision engineering that goes into every Mould component we produce.

Underpinning all these is our lead time of 2-4 weeks, which reflects our commitment to delivering quality in a timely manner. Whether it's for creating complex geometric components for automotive innovation, precision parts for life-saving medical devices, or robust and reliable elements for the latest consumer electronics, our custom mold parts are designed to perform. With our comprehensive services and dedication to quality, we empower industries to bring their most intricate designs to life, precisely and efficiently.

Place of Origin: China Fujian

Certification: ISO

Minimum Order Quantity: 100

Price: Negotiable

Packaging Details: Neutral Packing

Delivery Time: 30 days

Payment Terms: TT (Telegraphic Transfer)

Supply Ability: 10000+ pcs per month

Mold Size: Customized according to requirements

Cavity Number: Single Or Multiple options available

Application: Manufacturing, specifically for Plastic injection mold parts

Mold Life: 100,000 to 1,000,000 Shots

Production Volume: Capable of Small To Large Scale production

Note: We specialize in Mould design and can adjust specifications based on the unique needs of your project.

Our Mold Design product comes with comprehensive technical support and services to ensure that you can maximize the efficiency and productivity of your operations. We offer a range of services to support your needs, from software updates and maintenance to customized training sessions and professional consulting services.

Our team of experts is available to assist with any technical issues you may encounter, ensuring that your operations run smoothly. We provide detailed documentation and resources to help you troubleshoot problems, optimize your mold designs, and leverage the full potential of our product.

Additionally, we offer regular webinars and workshops to keep you up-to-date with the latest industry practices and software features. Our commitment to your success is reflected in our ongoing efforts to improve our services and provide you with the support you need to achieve your business objectives.

Our mold design products are packaged with utmost care to ensure that they reach you in perfect condition. Each mold is encased in a protective foam layer to guard against any impact during transit. The molds are then placed in sturdy cardboard boxes, which are sealed and reinforced to prevent any movement that could cause damage. We label each package with clear handling instructions to ensure that our shipping partners treat your product with the care it deserves.

Before dispatch, we conduct a final inspection to guarantee that the product meets our high-quality standards. We also include a detailed packing list that outlines the contents and provides handling instructions for safe and efficient unboxing. Our chosen courier services are reliable and offer tracking options so you can monitor your package's journey to your doorstep. Please inspect the package upon arrival and report any damage immediately so we can assist you with a prompt resolution.

Q1: What is the origin of your mold design products?

A1: All our mold design products originate from China, ensuring high-quality manufacturing standards.

Q2: Do your mold design products come with any certification?

A2: Yes, our products are ISO certified, which means they meet international standards for quality management and consistency.

Q3: What is the minimum order quantity for your mold design products?

A3: The minimum order quantity for our mold design products is 100 units, catering to both small and large-scale operations.

Q4: Can you provide the pricing details for your mold design products?

A4: Our mold design products are priced competitively at $1 per unit, providing cost-effective solutions for our customers.

Q5: How are the mold design products packaged and what are the delivery terms?

A5: Our mold design products are packaged using neutral packing to ensure safe transportation. The delivery time is approximately 30 days after order confirmation, depending on the order size and specific requirements.

Q6: What are the payment terms for purchasing your mold design products?

A6: We accept payment through TT (Telegraphic Transfer), providing a secure and efficient method of transaction.

Q7: How is the supply ability of your mold design products?

A7: We have a robust supply ability, capable of providing over 10,000 pieces per month to meet the demands of our clients.