Quanzhou Yuanyuan Cloud Technology Co., Ltd. |

|

Verified Suppliers

|

|

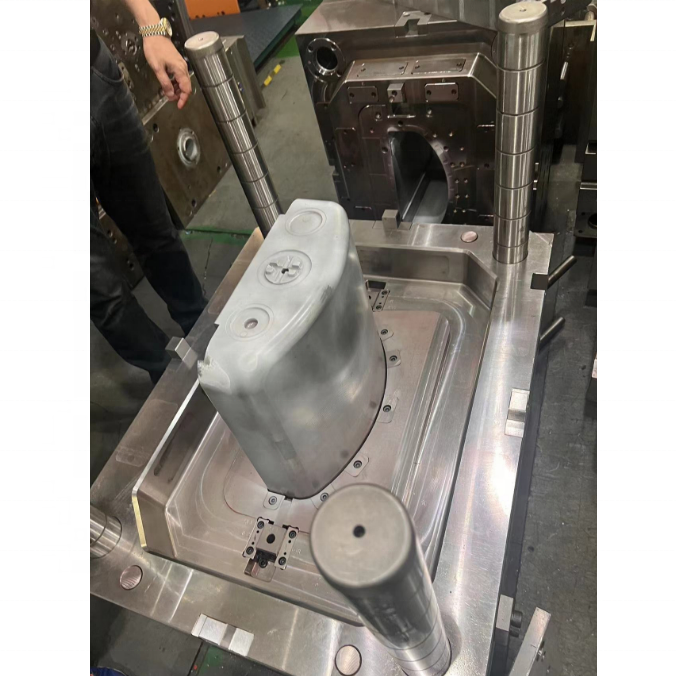

High Quality Bucket Mould Different Sizes Plastic Injection Mmold Making Mould Mold design

Our state-of-the-art industrial design product specializes in the meticulous creation of plastic injection mold parts, suitable for small to large scale production volumes. Crafted with precision, our product caters to a diverse range of industrial requirements, ensuring that each mold is designed to meet the highest standards of quality and efficiency. The mold design product we offer bridges the gap between innovation and functionality, providing customers with a reliable solution for their molding needs.

The versatility of our mold design is evident in its adaptability to both single and multiple cavity configurations. This flexibility allows for the customization of the mold to fit the specific production requirements of our clients, whether they are creating a unique prototype or mass-producing parts. With cavity numbers tailored to the task at hand, our clients can optimize their production processes, reduce waste, and increase overall productivity.

One of the paramount features of our mold design product is its impressive mold life. Engineered to withstand anywhere from 100,000 to 1,000,000 shots, our molds boast longevity and durability. This extended mold life not only ensures a consistent quality of plastic injection mold parts over time but also provides significant cost savings by reducing the need for frequent replacements.

The heart of our product lies in the design process, which utilizes the advanced technique of injection molding. This process involves the precise injection of molten plastic material into a custom-designed mold cavity, where it cools and solidifies to form the desired part. Our meticulous approach to the design process ensures that every detail of the mold is optimized for the highest quality of the end product. The result is a mold that delivers precision, accuracy, and repeatability in the production of plastic injection mold parts.

Injection molding as a design process offers numerous advantages. It allows for the production of complex and intricate parts, high levels of repeatability, and the efficient use of materials. Our product harnesses these strengths to provide a seamless and cost-effective molding solution.

Moreover, our commitment to excellence is evident in the rigorous testing and quality assurance procedures that every mold undergoes. From the initial design phase to the final production run, our team of experts ensures that every mold meets our stringent standards. We use state-of-the-art technology and the latest advancements in mold design to deliver a product that not only meets but exceeds the expectations of our clients.

In conclusion, our industrial design product for plastic injection mold parts stands as a beacon of innovation in the field of mold design. Suited for a wide range of production volumes, capable of enduring extensive use, and designed with the utmost precision and expertise, our molds are synonymous with quality and efficiency. Whether you require a single cavity for specialized productions or multiple cavities for high-volume runs, our product is designed to deliver unparalleled performance and longevity. Choose our mold design product for your industrial needs and experience the difference that comes with a meticulously crafted tool that is built to last.

| Attribute | Details |

|---|---|

| Product Type | Industrial Design |

| Material | Steel |

| Design Process | Injection Molding |

| Surface Finish | Polishing |

| Cavity Number | Single Or Multiple |

| Application | Manufacturing |

| Design Software | CAD |

| Production Volume | Small To Large Scale |

| Mold Size | Customized |

| Lead Time | 2-4 Weeks |

The design and application of molds, specifically tailored for industrial purposes, find their place of origin in China, a hub for manufacturing excellence. These molds, often used in the creation of plastic injection mold parts, are crafted with precision and adhere to the highest quality standards as evidenced by their ISO certification. The versatility and precision of these molds make them ideal for a wide range of applications and scenarios.

Manufacturers seeking to procure such high-quality mold designs must note the minimum order quantity of 100, with each unit priced competitively at 1. The molds are carefully packaged in neutral packing to ensure their integrity during transit. With a reasonable mold cost that varies depending on the complexity of the design, clients are assured that they are investing in a product where quality is uncompromised. The delivery time is set at 30 days, striking a balance between speed and precision in production.

The payment terms for these molds are straightforward, with transactions carried out through TT (Telegraphic Transfer), ensuring a secure and reliable process. Companies can plan their production schedules confidently, knowing that the supply ability stands at an impressive 10000+ pieces every 7 days. This remarkable output is achieved without sacrificing the material quality, as the molds are constructed from robust steel, guaranteeing longevity and durability.

These industrial design molds are integral to various occasions where plastic injection mold parts are required. They serve an essential role in the automotive industry, consumer electronics, home appliances, medical equipment, and many other sectors that demand precision-engineered components. The strict inspection and testing protocols underpinning the quality control measures ensure that each mold performs to its expected standards. The lead time for these molds ranges from 2-4 weeks, allowing for meticulous attention to detail while maintaining efficiency.

In summary, the application scenarios for these mold designs are extensive, catering to industries that require high-quality, precise plastic injection mold parts. With reliable delivery, solid material construction, and strict quality control, these molds represent a smart choice for businesses looking to optimize their production processes and enhance the quality of their products.

Place of Origin: China Fujian

Certification: ISO

Minimum Order Quantity: 100

Price: Negotiable

Packaging Details: Neutral Packing

Delivery Time: 30 days

Payment Terms: TT (Telegraphic Transfer)

Supply Ability: 10000+ pcs per month

Cavity Number: Single Or Multiple

Design Software: CAD

Mold Cost: Varies Depending On Complexity

Material: Steel

Tolerance: ±0.01mm

Our product customization services cater to your specific needs for Plastic injection mold parts , ensuring precision and quality. Every Mould is designed and manufactured in China Fujian under strict ISO certification standards. With a robust supply ability, we promise timely delivery and flexible payment terms for your convenience.

Our Mold Design Product comes with comprehensive technical support and services to ensure you get the most out of your investment. Our team is dedicated to providing you with expert assistance throughout the lifecycle of your product. From installation and configuration to optimization and troubleshooting, we are here to help.

Our technical support includes detailed documentation, online resources, and a knowledge base that is regularly updated with the latest information on product use and best practices. We also offer virtual training sessions to help your team become proficient in using our Mold Design Product.

If you encounter any issues or have any questions, our technical support team is available to provide you with timely and efficient service. We are committed to resolving any technical challenges you may face, ensuring minimal disruption to your design and manufacturing processes.

In addition to our standard support services, we offer advanced services such as custom mold design consulting, performance analysis, and enhancement recommendations to help you achieve optimal results. Our goal is to support your success by providing a full suite of services tailored to your specific needs.

Product Packaging for Mold Design:

Our mold design products are securely packaged to ensure they reach you in perfect condition. Each mold is encased in a protective foam layer that conforms to its unique contours, providing cushioning and preventing movement during transit. The foam is then placed inside a sturdy, corrugated cardboard box that is sealed with heavy-duty packing tape. Clear labeling on the outside of the box identifies the contents as fragile, ensuring careful handling by all carriers.

Shipping for Mold Design:

We take great care in the shipping of our mold design products to guarantee their safe delivery. Our standard shipping method includes tracking and insurance for the full value of the product. Upon dispatch, you will receive a tracking number to monitor the progress of your shipment. Packages are typically delivered within 5-7 business days, depending on your location. Expedited shipping options are available upon request for an additional fee. Please note that we cannot ship to P.O. Boxes and a signature may be required upon delivery to ensure the security of your high-value item.

Q1: What is the place of origin for your mold design products?

A1: The place of origin for our mold design products is China.

Q2: Do your mold design products have any certification?

A2: Yes, our mold design products are ISO certified, ensuring compliance with industry standards.

Q3: What is the minimum order quantity for your mold design products?

A3: The minimum order quantity for our mold design products is 100 units.

Q4: Can you provide the pricing details for your mold design products?

A4: The price for our mold design products is set at 1 unit per price point. For larger quantities, please inquire for a detailed quotation.

Q5: What are the packaging details for your mold design products?

A5: Our mold design products come with neutral packing to ensure safe transportation and handling.

Q6: How long does it take to deliver mold design products?

A6: The delivery time for our mold design products is approximately 30 days after order confirmation.

Q7: What are the payment terms for purchasing your mold design products?

A7: The payment terms for our mold design products are TT (Telegraphic Transfer).

Q8: What is the supply ability for your mold design products?

A8: We have a supply ability of over 10,000 pieces every 7 days for our mold design products.