Quanzhou Yuanyuan Cloud Technology Co., Ltd. |

|

Verified Suppliers

|

|

Mold maker Oem Metal Stamping Manufacturer Aluminum Stainless Steel Stamping Bending Sheet Metal Parts Customized Sheet

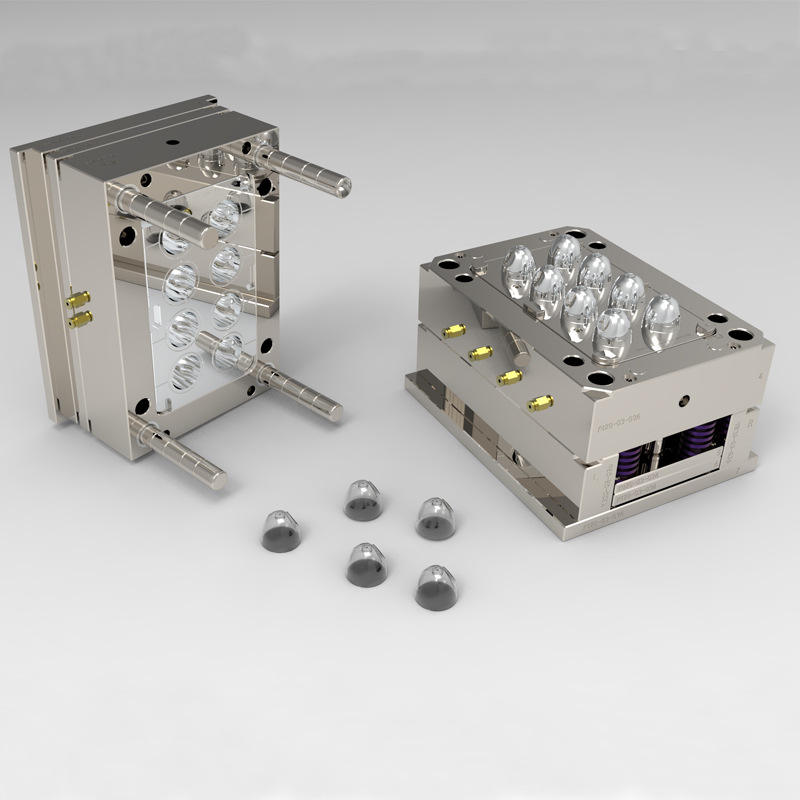

The epitome of precision and durability in mold design is encapsulated within our state-of-the-art product tailored for industries that demand the highest level of accuracy and reliability. Our mold design product, originating from the industrially advanced region of China Fujian, is a cutting-edge solution crafted for the creation of custom mold parts, as well as for plastic injection mold parts used in various sectors, including but not limited to automotive, consumer electronics, and medical devices.

With a remarkable tolerance of 0.01mm, our mold design product ensures that the minutest discrepancies are eliminated, resulting in parts that meet the most stringent of specifications. This level of precision is critical in industries where the difference of a micrometer can determine the success or failure of a product. Our clients can trust in our commitment to delivering molds that uphold the highest standards of accuracy.

Understanding that the cost is a pivotal factor for our clients, the mold cost associated with our product varies depending on the complexity of the design. We work closely with our clients to provide a cost-effective solution without compromising on quality. Whether you require a simple mold for low volume production or a more sophisticated mold for large-scale manufacturing, we offer scalable solutions that cater to your specific needs.

Our product is designed to accommodate production volumes ranging from small to large scale, providing our clients with the flexibility to ramp up their manufacturing processes as needed. The versatility of our mold design product allows for a seamless transition from prototype development to full-scale production, ensuring that our clients can meet market demands without delay.

Quality control is a cornerstone of our operation, and we enforce strict inspection and testing protocols to guarantee that every mold exiting our facility meets our high-quality standards. Our quality assurance team utilizes advanced inspection equipment and rigorous testing methods to ensure that every mold is free from defects and performs consistently under operational stresses. This meticulous approach to quality control results in a product that our clients can depend on for long-term performance.

The material used in the construction of our molds is of paramount importance, and that's why we employ steel in the crafting of our products. Steel is renowned for its strength, durability, and resistance to wear, making it the ideal choice for mold design. The use of high-quality steel not only extends the life of the molds but also ensures that they can withstand the rigorous conditions of repeated use, particularly in the case of plastic injection mold parts.

Our product is synonymous with excellence and innovation. The combination of high tolerance levels, variable mold costs, flexibility in production volume, strict quality control, and the use of robust materials positions our mold design product as a premier choice for businesses seeking custom mold parts. Whether you are based in China Fujian or any other part of the globe, our commitment to precision and quality remains unwavering. Choose our mold design product for an investment that delivers precision, efficiency, and reliability in your manufacturing process.

| Attribute | Detail |

|---|---|

| Mold Life | 100,000-1,000,000 Shots |

| Design Process | Injection Molding |

| Surface Finish | Polishing |

| Quality Control | Strict Inspection And Testing |

| Lead Time | 2-4 Weeks |

| Tolerance | 0.01mm |

| Material | Steel |

| Mold Size | Customized |

| Production Volume | Small To Large Scale |

| Mold Cost | Varies Depending On Complexity |

The intricacies of modern manufacturing demand precision and efficiency, where the use of high-quality mold designs plays a crucial role. Specifically, plastic injection mold parts are essential in various production scenarios, serving as a backbone for the creation of countless plastic components. These molds, designed and manufactured with meticulous attention to detail, originate from China Fujian, a hub known for its advanced industrial capabilities.

Our mold design product comes with a prestigious ISO certification, ensuring that each mold meets international standards for quality and reliability. The minimum order quantity for our molds is set at 100, catering to both medium and large-scale production needs. With a competitive price point of 1, we strive to offer our clients cost-effective solutions without compromising on quality.

Understanding the dynamic nature of manufacturing, we offer neutral packing for all mold shipments, ensuring that they arrive at their destination in pristine condition. Our delivery time is set at 30, showcasing our commitment to prompt service and the ability to meet tight production schedules. When it comes to financial transactions, we offer payment terms that rely on TT (Telegraphic Transfer), which is a secure and efficient method of payment.

The supply ability of our mold design product is robust, with a capacity to produce over 10,000 pieces every 7 days. This impressive output ensures that we can handle even the most demanding orders with ease. The application of our molds is primarily in the manufacturing sector, where they are used to create a vast array of plastic products through the process of injection molding.

Costs for our molds vary depending on their complexity. We offer both single and multiple cavity molds, which allows for versatility in production and the ability to meet diverse client requirements. The mold size is customized to fit the specific needs of each project, ensuring that every mold is perfectly tailored to the task at hand. Our design process is centered around injection molding, a technique known for its precision and ability to produce high volumes of plastic parts quickly and efficiently.

In summary, whether you are involved in the manufacturing of consumer goods, automotive components, or any other products requiring plastic parts, our molds from China Fujian are the ideal choice. With rigorous standards, flexible order quantities, and a robust supply chain, we are equipped to support your production needs and contribute to your success in the manufacturing landscape.

Place of Origin: China Fujian

Certification: ISO

Minimum Order Quantity: 100

Price: Negotiable

Packaging Details: Neutral Packing

Delivery Time: 30 days

Payment Terms: TT (Telegraphic Transfer)

Supply Ability: 10000+ pcs per week

Product Type: Industrial Design - Custom Mold Parts

Plastic Molding Type: Injection - Plastic Injection Mold Parts

Mold Cost: Varies Depending On Complexity

Quality Control: Strict Inspection And Testing

Surface Finish: Polishing to ensure high-quality custom mold parts

Our Mold Design Product comes with comprehensive technical support and services to ensure you can maximize its potential and efficiency. This includes extensive documentation, a library of tutorials, and a community forum where you can share insights and ask questions. Our support also includes regular updates and patches to improve functionality and security. Please note that active maintenance and support contracts provide access to our dedicated technical assistance team for more personalized support. We're committed to helping you resolve any issues quickly and effectively so that you can continue to deliver exceptional results with our Mold Design Product.

Product Packaging:

Our mold design product is carefully packaged in a durable, reinforced box to ensure it arrives in perfect condition. Each mold is encased in a protective foam insert that prevents movement and damage during transit. The packaging also includes a tamper-evident seal, guaranteeing that your product is brand new and has not been interfered with.

Shipping Details:

Once your order is confirmed, the product will be shipped within 2-3 business days. We use a trusted courier service to ensure that your product is delivered promptly and safely to your doorstep. Tracking information will be provided via email so you can monitor your package's progress. Please inspect the package upon arrival for any signs of damage during shipping and report it to us immediately for assistance.

Q1: What is the origin of the Mold design product?

A1: The Mold design product originates from China.

Q2: Does the Mold design product have any certifications?

A2: Yes, the product has ISO certification, ensuring international quality standards.

Q3: What is the minimum order quantity for the Mold design product?

A3: The minimum order quantity for the product is 100 pieces.

Q4: How is the Mold design product packaged?

A4: The product comes in Neutral Packing to ensure safety during transportation.

Q5: What are the payment terms for purchasing the Mold design product?

A5: The payment terms are TT (Telegraphic Transfer).

Q6: How long does it take to deliver the Mold design product?

A6: The delivery time for the product is approximately 30 days after order confirmation.

Q7: What is the price of the Mold design product?

A7: The price for the Mold design product is currently set at 1 unit of your currency.

Q8: What is the supply ability of the Mold design product?

A8: The supply ability for the Mold design product is over 10,000 pieces every 7 days.