Suzhou Lingyao Pharmaceutical Equipment Co., Ltd. |

|

Verified Suppliers

|

|

High-speed ampoule filler, Ampoule sealing and filling equipment,washing,sterlizing, filling and sealing-LYAPL1-20

The integrated production line features a sleek and attractive design, occupying minimal space and offering convenient cleaning. It is well-suited for the production of small-volume injection vials ranging from 1 to 20ml, and is capable of completing a series of process steps for pharmaceutical production, including water rinsing, ultrasonic cleaning, flushing, air flushing, drying sterilization, cooling, filling, and sealing of ampoules. The design concept of the integrated line is advanced, with a rational structure and stable performance, providing technical assurance for sterile drug manufacturing and meeting the relevant requirements of the current Good Manufacturing Practice (cGMP) for pharmaceutical production.

The streamlined appearance of the integrated production line not only enhances its visual appeal but also ensures efficient space utilization, making it suitable for pharmaceutical facilities with limited space. Its user-friendly design facilitates easy cleaning and maintenance, contributing to a hygienic production environment.

Furthermore, the line's capability to handle the entire process of water rinsing, ultrasonic cleaning, drying sterilization, and filling and sealing of ampoules in a coordinated manner underscores its efficiency and suitability for aseptic pharmaceutical production. The advanced design principles, rational structure, and stable performance of the integrated line provide essential equipment technology support for sterile drug manufacturing, aligning with the stringent quality standards mandated by cGMP.

In summary, the integrated production line not only embodies a modern and space-efficient design but also delivers reliable and efficient performance, making it an essential asset for pharmaceutical production facilities seeking to uphold the highest standards of sterile drug manufacturing.

| technical parameters | ||||

| product model | LYQCL120+LYASMR 620/43+LYAGF10 | |||

| size range | 1-20ml national standard ampoules | |||

| Output(1-2ml) | 22000-28000pcs/h | |||

| Output(5-10ml) | 12000-18000pcs/h | |||

| Output(20ml) | 6000-9000pcs/h | |||

| Clarity | >99% | |||

| Breakage rate | ≤1%(whole line) | |||

| Filling Precision | ±0.5-2%(according to pharmacopoeia standard) | |||

| Water Consumption and Pressure | 0.2-0.4Mpa / 0.6-1.0m³/h | |||

| Cleaning CA Consumption and Pressure | 0.3-0.6Mpa / 35-80m³/h 0.3-1.0Mpa / 35-80m³/h | |||

| Sealed gas | Gas(liquefied gas)+oxygen, oxyhydrogen generation gas, natural gas | |||

| Oxygen consumption | 0.2-0.3Mpa,1.2-1.5m³/h | |||

| Gas consumption | 0.1-0.3Mpa,1.5-2.5m³/h | |||

| Exhaust volume | 3500-4100m³/h | |||

| Net weight | 7800(kg) | |||

| Total power | around 91kw 380V 50HZ | |||

| Outline size | around 10100x2260x2445mm | |||

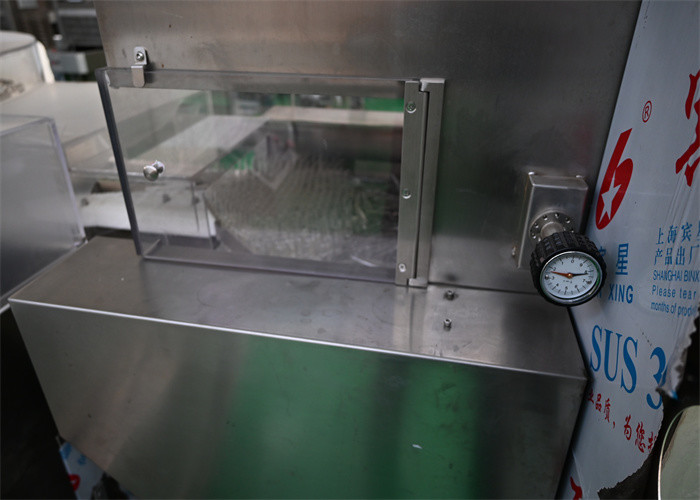

This vertical ultrasonic bottle washer adopts a combination of ultrasonic online cleaning and separate alternating water and air jet cleaning, making it the most popular and effective cleaning equipment internationally with excellent visible foreign matter detection. It has a wide adaptability and low bottle breakage rate. Throughout the entire cleaning process, water and air are sprayed independently through separate nozzles, with each nozzle fixed for a specific cleaning medium to complete a rinsing or cleaning process, thus avoiding cross-contamination and dead corners, in compliance with the requirements of the new version of GMP.

The innovative design of the vertical ultrasonic bottle washer ensures thorough and efficient cleaning by integrating ultrasonic online cleaning with separate water and air jet cleaning. This approach not only enhances the cleaning effectiveness but also enables superior detection of visible foreign matter, meeting the highest industry standards. The equipment's wide adaptability and low bottle breakage rate make it suitable for a diverse range of applications, contributing to its versatility in pharmaceutical and other industries.

Moreover, the independent spraying of water and air through dedicated nozzles for specific cleaning media ensures a meticulous and contamination-free cleaning process, eliminating the risk of cross-contamination and ensuring comprehensive coverage without any blind spots. This meticulous approach aligns perfectly with the stringent requirements of the latest version of GMP, underscoring the equipment's compliance with the highest standards of pharmaceutical manufacturing.

In summary, the vertical ultrasonic bottle washer's advanced cleaning technology, wide adaptability, low bottle breakage rate, and meticulous cleaning process make it an indispensable asset for pharmaceutical and other industries, ensuring superior cleaning efficacy and compliance with the latest GMP standards.