Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

Please provide more information as you can, we'll try to advice you detailed solutions according the furnace!

China refractory manufacturer factory price high alumina anchor brick for furnace or kiln ceiling insulating usage

The alumina content of high alumina anchor bricks is more than 55%,

and the alumina content of high-quality anchor bricks can reach

85%. But in general, the alumina content is 55%, because the anchor

brick with 55% content is more flexible.

The alumina content of high alumina anchor bricks is more than 55%,

and the alumina content of high-quality anchor bricks can reach

85%. But in general, the alumina content is 55%, because the anchor

brick with 55% content is more flexible.

In addition, it should be noted that the anchor brick is used to anchor the refractory castable. The properties of the anchor brick should be consistent with the castable material, and the expansion and contraction should be consistent, so that it can form a close combination with the castable and prolong the life of the furnace lining.

The layout and masonry of anchor bricks during use should follow the following principles:

1. The arrangement of anchoring bricks should be determined according to the range and frequency of temperature changes and the size of the area facing the wall, usually not less than 6 blocks/m2.

2. The anchoring bricks must be carefully checked before masonry. If the anchoring bricks have cracks at the anchoring holes that affect the overall strength of the anchoring bricks, they cannot be used and should be resolutely discarded.

3. When the masonry is close to the position of the anchoring brick, the bricks should be pre-arranged to determine the exact position of the anchoring brick. The welding part of the metal shell should be thoroughly cleaned with a wire brush, and the welding rod suitable for the welding parts should be used for firm welding. Good anchor tube.

4. Insert the anchoring hook after the anchoring brick is built, and fill the air strike with refractory fiber felt and plug it tightly to form a certain protection for the anchor.

| Item | Clay brick | High alumina brick | ||||||

| SK-30 | SK32 | sk34 | sk35 | sk36 | sk37 | sk38 | sk40 | |

| AL2O3 % min | 30 | 35 | 38 | 45 | 55 | 65 | 70 | 82 |

| Fe2O3 % max | 2.5 | 2.5 | 2 | 2 | 2 | 2 | 2 | 2 |

| Refractoriness℃(SK) | 30 | 32 | 34 | 35 | 36 | 37 | 38 | 40 |

| Refractoriness 0.2 MPa ℃ | 1250 | 1350 | 1370 | 1420 | 1450 | 1480 | 1530 | 1600 |

| Apparent Porosity(%) | 22-26 | 20-24 | 20-22 | 18-20 | 20-23 | 20-23 | 20-22 | 18-20 |

| Bulk Density(g/cm³) | 1.9-2.0 | 1.95-2.1 | 2.1-2.2 | 2.15-2.22 | 2.25-2.4 | 2.3-2.5 | 2.4-2.6 | 2.5-2.7 |

| ColdCrush Strength Mpa | 20 | 25 | 30 | 40 | 45 | 50 | 60 | 70 |

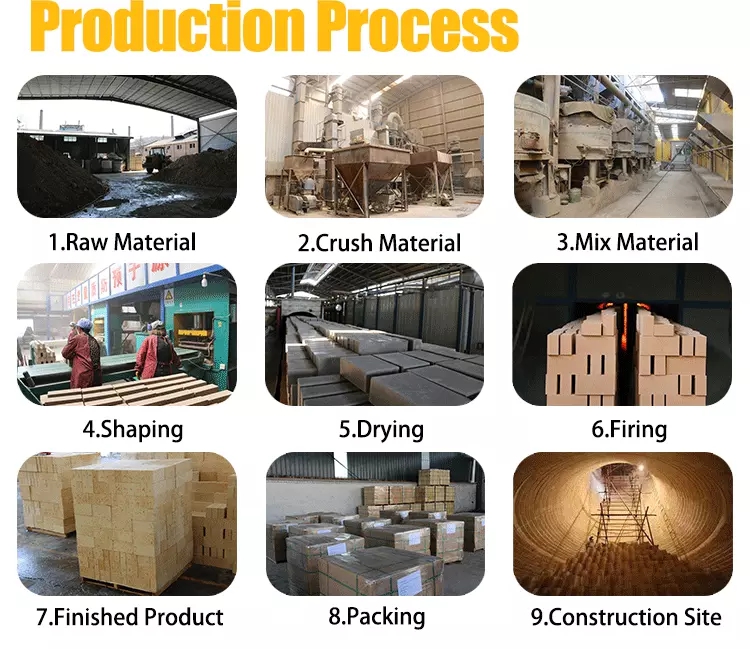

1. high alumina anchor brick Production Process

Crushing→Mixing→Shaping→Drying→Firing→Inspection→Packaging and

Shipment

2. high alumina anchor brick Quality Assurance

HongTai Refractory is committed to high quality standards for all

its products and services. With its thirst on State of the art

technology at every level and a wide range of products, HongTai

Refractory can provide ideal solutions for the stringent

requirement of the customer. Backed by decade of experience in

different industries, and close association with customers,HongTai

Refractory will always bring new products which will give better

life and value to the user.

The quality assurance system of high alumina anchor brick consists of the following steps:

The quality assurance system of high alumina anchor brick consists of the following steps:

1. Inspection and Control of incoming raw materials:According to the

chemical content,raw materials are classified into different levels

to ensure quality of brick first.

2. Inspection and process control:During the production, each brick

weight twice to reduce weight error.

3. Inspection of product Standardization of quality of each product by

process control and experimentation.

4. Taking corrective measures whenever deviations are noted.

Usage for High alumina anchor brick:

Iron & steel making industry: Blast furnace,hot blast furnace(stove),pellet shaft furnace,hot metal ladle,steel ladle,tundish,eating furnace,soaking pit furnace,heat treatment furnace,refining furnace,reheating furnace,metal mixter furnace,cupola furnace etc thermal technology equipment

Non-ferrous Metal industry: Smelting furnace, reverberatory furnace etc

Building materials industry: Cement kiln,glass kiln,ceramic kiln,lime kins,kiln car,tunnel kiln,rotary kiln

Energy&Incineration: Coke oven,general boiler,power generation boiler,circulating fluidized bed boiler,electric furnace,carbon roasting furnace,waste incinerators

Others: Petrochemical industry furnace

Henan Hongtai Kiln Refractory Co., Ltd. is established in 2012 and located in Xinmi city, 40 kilometers southwest of Zhengzhou city. Rich resources of refractory materials, adequate and qualified fuel in this area, provide unique conditions for refractory production.

Main products are high alumina brick, clay brick, silica brick, fused zirconium corundum brick, magnesia brick, carbon brick, fireproof ball lightweight insulation brick, wear-resistant pouring material, corundum pouring material, low cement highigh alu strength pouring material, impermeable material, self-flowing material, plastic material, and various types of refractory materials.

Quality first, reputation first, customer first is our aim;Scientific management, strong technical force, perfect testing means, advanced technological equipment and stable product quality are the guarantee of quality service.Henan hongtai kiln refractories co., LTD sincerely hopes to cooperate with you hand in hand and in good faith.

Packaging high alumina anchor brick

1.Pallet+Paper or Steel angle bead+Paper board +Plastic or Steel belt +Plastic film

(1)Wooden pallet size:Usually0.92*0.92m(standard high alumina brick),but 1*1m (special shape high alumina brick) at most,

(2)Load weight of each pallet:Usually 1.5-1.7Tons, max 2.0 Tons.

(3)20 Foot Container can be loaded max 25-26Tons, about 13-16Pallets.

2.Can make the high alumina brick package according to customer's

requirements.

Shipping for high alumina anchor brick

1.FEDEX/DHL/UPS/TNT for samples.

2.By Sea for batch goods.

3.Customers specifying freight forwarders or negotiable shipping methods!

4.Delivery Time for high alumina brick:

(1)High alumina brick samples:3 days for common shape samples;15 days for special shape samples.

(2)Batch goods:Within 7-10days for in stock high alumina bricks from ordering shipping space to deliver goods and within20-30 days for NO in stock high alumina bricks.

Payment Terms for high alumina anchor brick

(1)T/T, Western Union,LC;

(2)Usually 30% deposits,70% balance to be paid before delivery or against copy of BL or negotiations

Others

High alumina brick MOQ: Usually 1 container, MOQ 1Tons, Customers can order certain PCS for special high alumina brick.

Q1:Are you a manufacturer or trader?

A:Factory+trade(mainly factories,meanwhile,we operates other related products)

Q2:What's the MOQ of trial order?

A:No limit, We can offer the best suggestions and solutions according to your needs.

Q3:After an order is confirmed,when deliver?

A:15-25days after deposit; if customer sized, 35days.

Q4:Which payment terms can you accept?

A:T/T,L/C,Western Union,Moneygram,Paypal are available

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary

certification.

Q6:Can you offers samples?

A:Of course, samples are free but freight paid by the buyers.

Q7: What is the service life of your bricks?

A:Depend on brick types, using conditions and methods.

Q8: Can we visit your factory?

A:Of course,welcome to visit at any time. Seeing is believing.

Hongtai Kiln Refractory has professional sales and after-sale

service team who provide customers all-around service about high

alumina brick product selection, transportation, installation and

operation technology training etc. Now we have established

cooperation relationship with many science and research units and

our high alumina products have been sold to Vietnam, Thailand, Malaysia, South Korea, Pakistan, Kazakhstan, India, Japan, Indonesia, Germany, Italy, Mongolia, Russia, Argentina,

Eygpt, South Africa and etc.

We has 10 years experience on producing high alumina anchor brick.

Payment Guarantee: If couldn't trust us at first order, could use trade Assurance.

Jerry Li

Cell&WhatsApp: 0086-13373957739

Email: jerry(at)ht-refractory.com