Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

China zhengzhou refractory manufacturer LG 0.6 LG0.8 LG1.0 High alumina insulating fire bricks for thermal insulation

The purpose of high alumina insulating bricks used in kiln construction is to insulate the body, also known as light bricks. Correspondingly, there is another kind of heavy brick, which is used for laying kilns and belongs to firebrick series.

Light weight high alumina insulating bricks, often called thermal refractory bricks, also called thermal refractory bricks. First of all, literally, the weight of a light and heavy high aluminium brick is a very different product. Light weight high aluminium insulating brick, also called heat insulation high aluminium brick, its essential purpose is heat insulation and heat preservation function. In normal use without direct contact with furnace temperature, is a kind of close to the furnace wall, with heat insulation and heat preservation effect of firebrick products.

High alumina insulating brick usually are used high alumina clinker

plus a small amount of clay, after grinding with gas generation

method or foam method in the form of mud pouring shape, through

1300 ~

1500℃ fired. Sometimes industrial alumina can be used in place of

some bauxite clinkers. It can also be used for lining and

insulating layer of kiln, and parts without strong erosion and

scouring effect of high temperature melting material. Direct

contact with the flame, the surface contact temperature should not

be higher than 1350℃.

With high porosity, good heat insulation performance, high temperature resistance, Light weight and high aluminium bricks are suitable for masonry industrial furnaces of heat insulation layer, insulation layer, can reduce the weight of the furnace, shorten the furnace time, reduce heat diffusion, protect uniform furnace temperature and other characteristics.

Because of its chemical structure, High Alumina insulating brick has the following six characteristics:

1. Low thermal conductivity, good heat insulation effect;

2. low impurity content has a very low iron box alkali metal oxide content, therefore, high refractoriness; The high aluminum content makes it maintain good performance in reducing atmosphere.

3. High thermal compressive strength;

4.the appearance of accurate size, speed up the building speed, reduce the amount of refractory mud, ensure the strength and stability of the masonry, thereby extending the life of the lining;

5. can be processed into special shape, to reduce the number of brickwork and joints.

China refractory manufacturer LG 0.6 LG0.8 LG1.0 High alumina insulating fire bricks for thermal insulation

High alumina insulating brick technical data:

High alumina insulating brick technical data:

Items | LG-1.0 | LG-0.9 | LG-0.8 | LG-0.7 | LG-0.6 |

Al2O3 ≥ | 48 | ||||

Fe2O3 ≤ |

| 2.0 | |||

Bulk density g/cm3≤ | 1.0 | 0.9 | 0.8 | 0.7 | 0.6 |

Cold crushing strength Mpa ≥ | 4.0 | 3.5 | 3.0 | 2.5 | 2.0 |

Permanent linear change temperature≥ | 1400 | 1400 | 1400 | 1350 | 1350 |

Thermal conductivity W/m.k 350±25 ≤ | 0.50 | 0.45 | 0.35 | 0.35 | 0.30 |

China refractory manufacturer LG 0.6 LG0.8 LG1.0 High alumina insulating fire bricks for thermal insulation

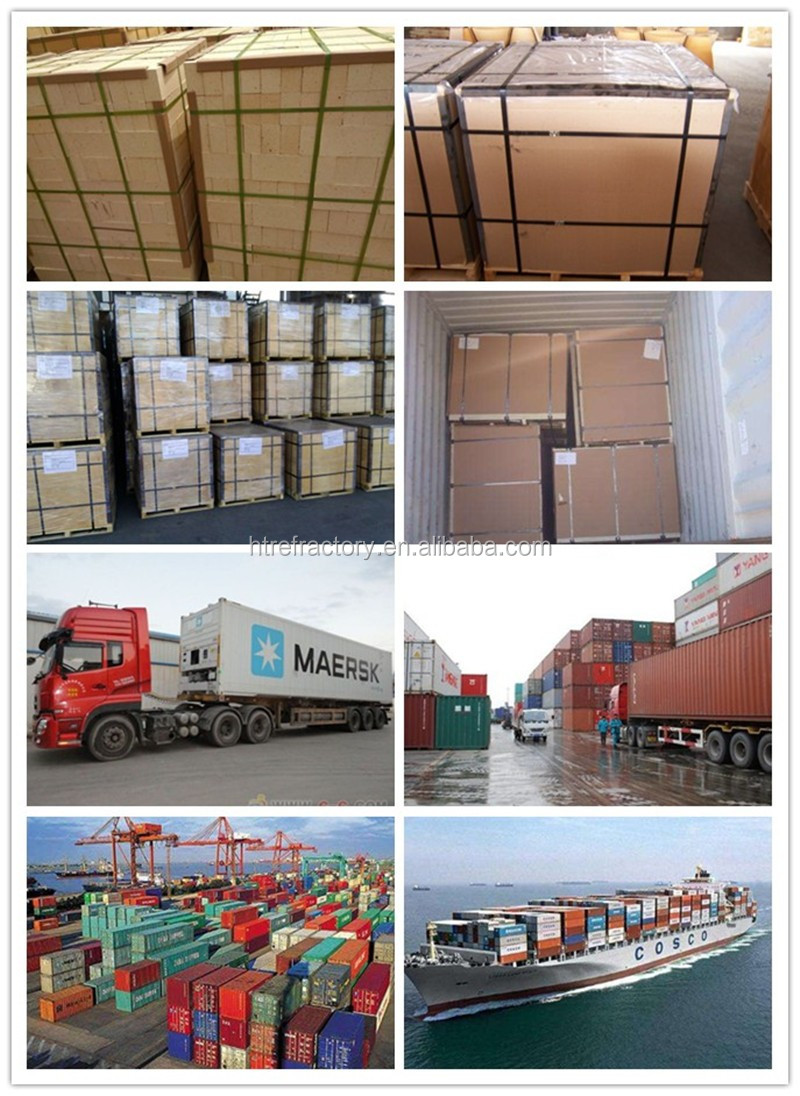

Packaging of Light Weight High Alumina Insulating Bricks

1.on wooden pallets with plastic cover: wooden pallet size :930*930

or 1000*1000mm,

2.Load weight of each pallet: 1.5-2.0 tons,

Shipping of Light Weight High Alumina Insulating Bricks

1.Our packaging is as per customer’s request

2.Normal goods delivered by sea transport

3.Sample shipping by express

4.We will shipping and delivery goods timely, quality and quantity

guaranteed, and also in accordance with the contract and customer's

requirement completely.

Delivery of high alumina insulating brick:

15-30 days working day for large quantity. The shipment we will

arrange as soon as possible. Of course, if it is a custom products,

the shipping time will delay.

Sample:

Usually by EMS, DHL, UPS, TNT, FedEx. Anyway you like. Bulk order: Usually by sea.

Payment:

It can be through T/T, L/C at sight. The specific terms determined

according to the quantity of the goods.

Your inquiry related to our product & price will be replied

within 24 hours.

Export:

Our products have been exported to many countries: Australia,

Chile, USA, Russia, UK, Indonesia, etc., good quality have be

approved by our clients.

High alumina insulating bricks for furnace best price

Henan hongtai kiln refractory co., LTD. Is well aware that there

are thousands of demands from customers, which can be summarized in

four aspects: reliable quality, timely delivery, reasonable price

and considerate service.The company will continue to adhere to the corporate spirit of

"contributing to society and serving customers" and the business

philosophy of "mutual benefit, win-win, integrity, efficiency,

preciseness and responsibility".Our company is willing to develop a wide range of technical

exchanges with colleges and universities and colleagues from all

walks of life at home and abroad in a flexible and diversified way.

Henan hongtai kiln refractory co., LTD. Is well aware that there

are thousands of demands from customers, which can be summarized in

four aspects: reliable quality, timely delivery, reasonable price

and considerate service.The company will continue to adhere to the corporate spirit of

"contributing to society and serving customers" and the business

philosophy of "mutual benefit, win-win, integrity, efficiency,

preciseness and responsibility".Our company is willing to develop a wide range of technical

exchanges with colleges and universities and colleagues from all

walks of life at home and abroad in a flexible and diversified way.

Henan hongtai kiln refractory co., LTD. Main products are high alumina brick, clay brick, fused zirconium corundum brick, fireproof ball lightweight insulation brick, wear-resistant pouring material, corundum pouring material, low cement high strength pouring material, impermeable material, self-flowing material, plastic material, and various types of refractory materials.For different industries, the cement industry with anti-flaking high-alumina bricks, alkali resistant bricks, phosphate bricks;Boiler industry USES all kinds of brand wear-resisting brick, corundum brick, mullite brick and other finalizing materials.

Henan hongtai kiln refractory co., LTD. : "quality first, reputation first, customer first: it is our aim."Scientific management, strong technical force, perfect testing means, advanced technological equipment and stable product quality are the guarantee of quality service.Henan hongtai kiln refractories co., LTD sincerely hopes to cooperate with you hand in hand and in good faith.

High alumina insulating bricks for furnace best price

Q1:Are you a manufacturer or trader?

Q1:Are you a manufacturer or trader?

A:Factory+trade(mainly factories,meanwhile,we operates other related products)

Q2:What's the MOQ of trial order?

A:No limit, We can offer the best suggestions and solutions according to your needs.

Q3:After an order is confirmed,when deliver?

A:15-25days after deposit; if customer sized, 35days.

Q4:Which payment terms can you accept?

A:T/T,L/C,Western Union,Moneygram,Paypal are available

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary

certification.

Q6:Can you offers samples?

A:Of course, samples are free but freight paid by the buyers.

Q7: What is the service life of your bricks?

A:Depend on brick types, using conditions and methods.

Q8: Can we visit your factory?

A:Of course,welcome to visit at any time. Seeing is believing.

Q9:How to solve the quality problems?

A:If the products have quality problems, we will be responsible to offer compensation.

Hongtai Kiln Refractory has professional sales and after-sale service team who provide customers all-around service about product selection, transportation, installation and operation technology training etc. Now we have established cooperation relationship with many science and research units and our products have been sold to Vietnam, Thailand, Malaysia, South Korea, Pakistan, Kazakhstan, India, Japan, Indonesia, Germany, Italy, Mongolia, Russia, Argentina, colombia, Eygpt and etc.

We has over 20 years experience on producing High alumina insulating bricks.

Payment Guarantee: If couldn't trust us at first order, could use trade Assurance.

Jerry Li

Cell&WhatsApp: 0086-13373957739

Email: jerry(at)firebricks-supplies.com