Weifang Guote Mining Equipment Co., Ltd. |

|

Verified Suppliers

|

|

calcium carbonate machinery air classifier machine for Dry powder 2-150 micron classifying

1. Applications of Air Classifiers:

Series GF Air Classifier (Series GF Pneumatic Classifier)(For

details, please contact me:Annie

Chang,Mob:0086-18678029069(whatsapp),E-mail: Annieflower.chang dot

sdguote.com)

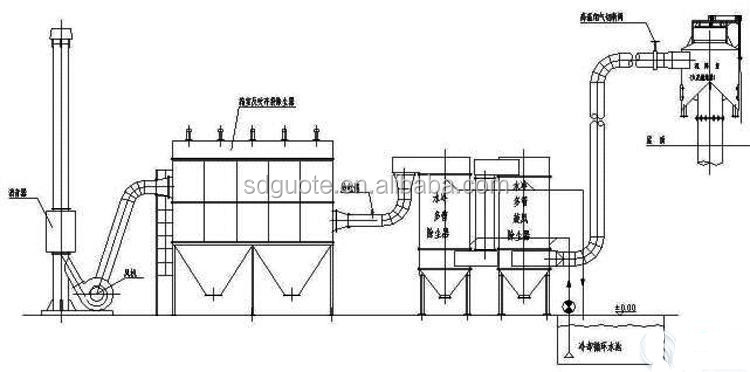

The classification device is composed of pneumatic classifier,

cyclone, collector , induced draft fan,conmtrol cabinet etc . Equiped with second air inlet and vertical impeller rotor ,the

materials are fed in visa the bottem roller under the force

generated from the induced draft fan and then mixed with first

input air to disperse particle and then brought to classifying zone

.

Owing to the high rotary speed of classifying rotor, the particles

are under the centrifugal force produced by the rotor and

centripetal force generated from induced draft fan . When the

centrifugal force is stronger than then centripetal force , the

coarse particles fall down along inside roller. the second air is

induced to sieve the coarse materials and seperate the fine powder

that stick on or mixed with coarse . after the coarse material is

discharged from classifier . the over -milled powder are collected

by the cyclone and pulse collector .

2. Work Principle:

As a forced centrifugal classifier with secondary air entry and

stand grading rotor, the classifier is composed of grading rotor,

guide vane rectifier and screw feeder. The materials are fed

through the upper cartridge and the grains will be sieved and well

distributed by the incoming air, which brings the grain to the

grading zone. The centrifugal force produced by the fast rotation

of gather in the centripetal force by the pneumatic atheism act on

the grading grains when the centrifugal force on the grain is

greater than the centripetal force. The coarse grains above the

grading range will be swirled down along the untrained wall, the

second air will be rectified to uniform cockney through the guide

wane and separate the thinner grains from the discharge port. The

thinner grains below the grading range will be blasted to cyclone

separator and collector whereas the purified air will be vented

outside.(For details, please contact me:Annie

Chang,Mob:0086-18678029069(whatsapp),E-mail: Annieflower.chang dot

sdguote.com)

3.Technical Parameter

4. Technical Features:

1,The classifier used within the ceramic protection, less equipment wear,no pollution,high purity.

2,classifier structure is designed,almost by all large particles, high grading precision,large granular control.

3,classification by grading impeller speed and fan free to adjust the air volume, in order to obtain the required product, grading range.

4,adopts low speed vertical single impeller hierarchical structure , material flow is stable, equipment processing capacity,high classification effciency.

5,using multi-stage structure,at the same time granularity

classification of several products,the particle size distribution

to obtain the ideal.(For details, please contact me:Annie

Chang,Mob:0086-18678029069(whatsapp),E-mail: Annieflower.chang dot

sdguote.com)

5. Product Details

1.Higher Capacity

Special designed for coarse final product with higher capacity.

Secondary air design improves the classifying efficiency.

2.Higher Hardness Material

Inside are easy for wear-resistant with kind of material, which can

be suitable for material with higher hardness.

3.Higher Flexible Design

According to customers' workshop height, the motor driven way can

be direct or belt. Inlet also can from top or from bottom.

4.(For details, please contact me:Annie Chang,Mob:0086-18678029069(whatsapp),E-mail: Annieflower.chang dot sdguote.com)

6. Customer Case

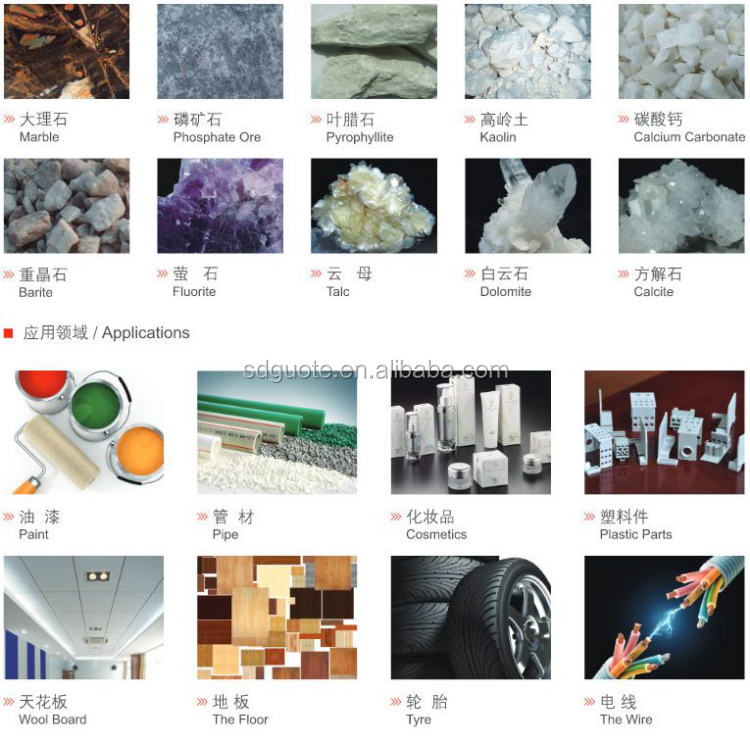

7. Application

standard export container,20GP,40GP ,40HQ,FR container,in bulk, the spare parts in wooden case

or according to the customer's requirements

COMPANY INFORMATION

Weifang GUOTE Mine Equipment co.ltd. is professional and modern enterprise including research and development, engineering design, production and installation, debugging services , automatic control equipment, non-metallic mineral production line test, design, consultation and the complete line of delivery.The scope of services related to mining, metallurgy, electric power, coal, glass, paper, chemical building materials, refractory materials, tiles,food, cement ,etc.Our product sell well in more than thirty provinces, autonomous region.

Our product have electromagnetic, permanent magnetic separator, dry wet magnetic separator,electromagnetic vibration feeder, quartz sand making machine, air classifier, dust collector, water separator, washing machine, flotation machine,metal detector, screw conveyor, timing quantitative feeding,weigher and centralized control system, etc.

Facing the new opportunities and challenges, the company in line with the spirit of "honesty-oriented, mutual benefit, cooperation and innovation" , dedicated to providing “dependable,simple and efficient” products and services to customers, make enterprises become domestic advanced mining equipment manufacturer.

Our company is willing to work together with people from all walks of life for a better future.

OEM Service

We could make whole production line or single equipment following different clients requirements.

For whole process as below:

Firstly Please offer detailed technical drawing in CAD or requirements.

Secondly we will offer different technical proposals follwing offered drawings or requirements for clients.

Thridly make decision for which proposal

At last manufacture whole equorements following techncial proposal and holding test in warehouse.

Finally finished equipment/prodcution line offered as turn-key project.