Weifang Guote Mining Equipment Co., Ltd. |

|

Verified Suppliers

|

|

mineral grinding machine GMF Ball Mill Classifying silica flour Production Line

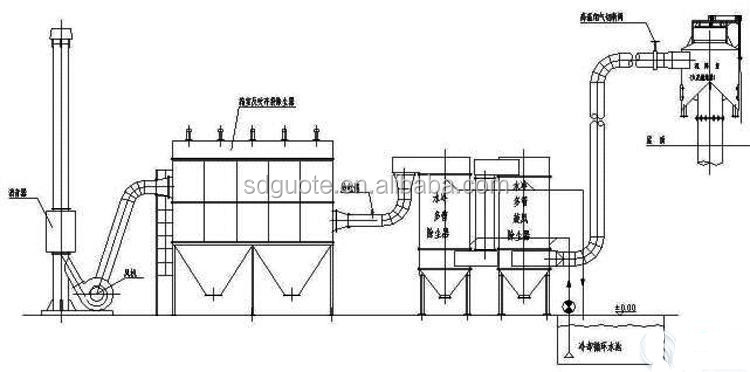

Principle of operation

Ball mills are giant drums that are filled to between 30 and 40% of their volume with freely moving grinding media - in this case balls. The diameter of the balls is between one and several centimetres to suit the application - smaller balls for fine milling results and larger ones for coarser milling tasks.

The drive sets the milling drum into slow rotation and the bed of milling media is thus activated, i.e. the balls are lifted and then impact back against the bed. Ball mills are usually operated at 75% of the critical speed. The critical speed is the speed where, mathematically calculated, the grinding media would centrifuge out. Mills of 2 m in diameter therefore rotate in operation at about 23 revolutions per minute, which corresponds to a peripheral speed of 2.4 m/s.

A mill of this size equipped with steel grinding media converts approx. 50 kW per m³ of feedstock. The feed product is fed continuously through the trunnion and is discharged through slots on the opposite side. The discharge rate can be adjusted as a function of the number of open slots. The ground product is transported - often pneumatically - and is charged to a downstream classifier. The coarse material is returned to the mill together with the feed product.

Features

The classic standard design which has proved itself in operation throughout the world for decades. Both the design and efficiency are continually improved to pay tribute to new technology and market requirements.

*Cast side plates bolted to a rolled-steel drum with integrated manhole.

*Drive via ring-and-pinion gear with automatically controlled tooth lubrication, back gearing with couplings and high-performance gear unit.

*Bearing unit: journal bearing designed as a friction bearing with permanent oil-recirculation lubrication and

temperature control.

*Option: self-aligning roller bearings.

*Product discharge via adjustable slots located around the periphery of the drum. Two-part discharge housing

*with top venting connection and inspection cover.

Variable-speed drive

Ball mills are usually operated at 75% of the critical speed, i.e. in the fringe area between cascading and free-fall. With a specially designed frequency converter, it is even possible to operate a heavy ball mill at variable speed. And if the GF is to be used for grinding ultrafine products or if it is planned to change the product frequently, operation with a frequency converter is particularly advantageous.

Load cell technology results in precision product level control

A high consistency of the product quality demands exact measurement of the amount of product in the mill. Because of this, an optional accessory offered for our ball mills is the load cell system which permits precision control of the product level. The complete ball mill is bedded on a steel or concrete frame designed to rest on a defined number of load cells. The load cells are integrated into a control unit and determine the total weight of mill, grinding media and product. The addition of virgin feed can be controlled with such precision that the mill always operates at optimum load. This means reliable prevention of no-load operation or overfilling, and mill operation is exceedingly cost-effective.

CE Superfine Ball Mill Classifying Production Line for silica powder,Gypsum, Glass, Cement Clinker, Ceramic, etc for quartz , felspar ,calcite , marble , carborundum , ,sand etc. (For details, please contact me:Annie Chang,Mob:0086-18678029069(whatsapp),E-mail: Annieflower.chang dot sdguote.com)

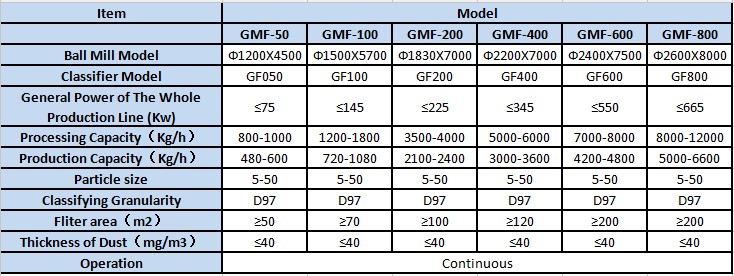

2. Specifications

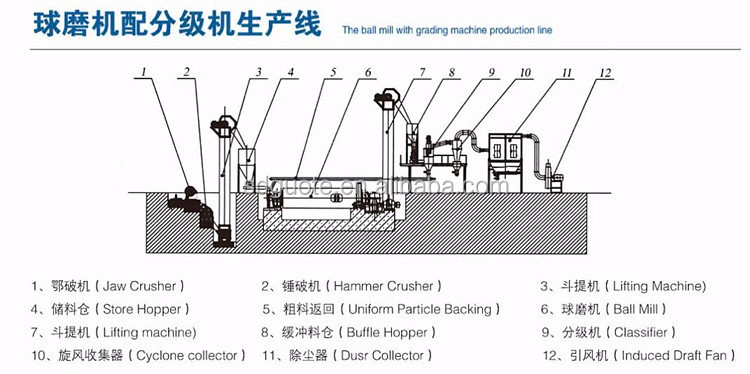

3. Working principle

Working Principle of Superfine Ball Mill Grinding Production Line GMF:

4. Technical Parameter

5. Features of GMF Superfine Ball Mill classifying Production

Line :

1. Low energy consumption: GMF superfine ball mill production line

adopted high advanced energy-saving technology and classification

technique; as a result, our production line can save over 40%

energy for producing same quantity materials.

2. Several times of classification could be obtained:

Finished product fineness after classification: 120-200mesh,or

200-325mesh,or 325-2500mesh,or 2500- 6,250mesh (d97≤2um).According

to customer requirements.

3. Adopted highly advanced self-diffluent classification system:

4. Scientific grinding medium enable us to produce large quantity

superfine particles.

5. Different lining boards and grinding mediums are available for

milling different materials, so as to guarantee the purity and

whiteness of finished products.

6. Scientific machine structure enables a lower investment cost;

7. Low failure rate and stale operation: because our ball mills and

classifiers in the production lines are PLC controlled and have

high automation;

8. Negative pressure production condition gives a good production

environment;

9. High annual production capacity: 5-500 thousand tons.

6.Product Details

7. Customer Case

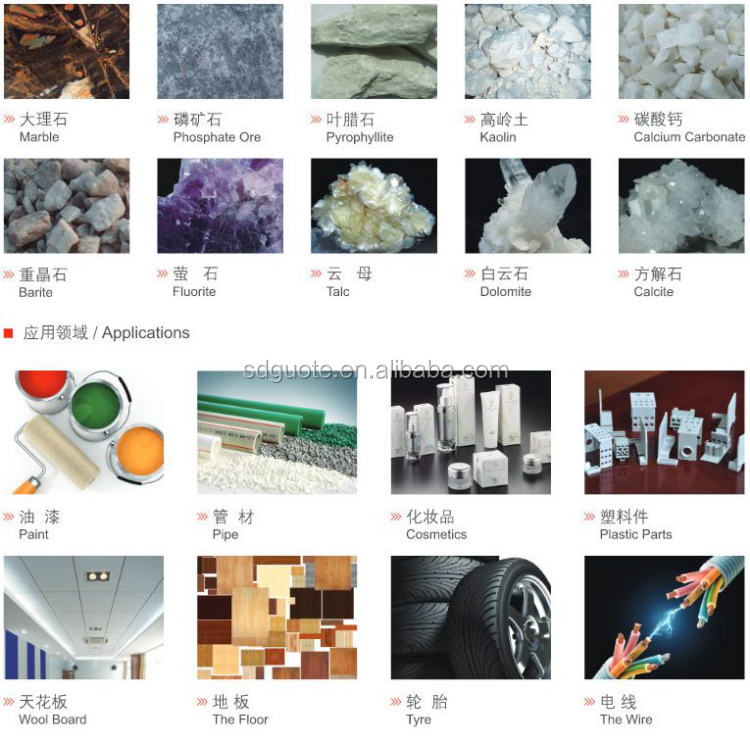

8. Application

(For details, please contact me:Annie Chang,Mob:0086-18678029069(whatsapp),E-mail: Annieflower.chang dot sdguote.com)

=

=

1.Equipment painting completed before shipment, With Stretch film to avoid rub off the surface paint, It can used wooden cases packaging according to users requirements.(Key parts such as electric cabinet with shockproof packaging material and then packed in wooden cases. )

2. We have 15 experienced engineers, With 108 skilled workers insure good quality of our machines and prompt delivery.

3.Meanwhile our company has a long-term cooperation with ACL, CSCL, CCNI,CNC, COSCO etc insure the goods to the port on time.

1. Packaging: Specially made wooden boxes and containers.Equipment

painting completed before shipment, With Stretch film to avoid rub

off the surface paint, It can used wooden cases packaging according

to users requirements.(Key parts such as electric cabinet

with shockproof packaging material and then packed in wooden cases.

)

2 Shipping: 5-45 days after receiving initial payment .Meanwhile

our company has a long-term cooperation with ACL, CSCL, CCNI,CNC,

COSCO etc insure the goods to the port on time.

3. We have 15 experienced engineers, With 108 skilled workers

insure good quality of our machines and prompt

delivery.(For details, please contact me:Annie

Chang,Mob:0086-18678029069(whatsapp),E-mail: Annieflower.chang dot

sdguote.com)

Pre-sales Service:

The wide product range enables us to provide our customers with

individual machines or complete processing plants. Based on our

customers’ request and budget, our experts make efficient, reliable

solutions, and we produce strictly follow customers’ order. What’s

more, every customer has the chance to visit the working machine in

the site before placing the order. (For details, please contact me:Annie

Chang,Mob:0086-18678029069(whatsapp),E-mail: Annieflower.chang dot

sdguote.com)

Most of the visiting foreign customers feel inconvenient for the

first time. Due to this condition, we help to arrange cars, hotels,

and translators for every visiting customer.

After-sales Service:

Experienced technicians guidance is available on the phone, and on

the internet. One or more engineers will be dispatched to the

quarry site to help install the customers’ plants. Necessary

training about machine daily maintenance to local workers is

provided also.

After-Sales department is made of well-trained employees, and

installation engineers. The installation technicians are special

and professional team of SBM; they are now strategically located

home and abroad, working for our customers

1.What main products do you supply?

2 . Are you a trading company or factory?

3 Delivery date for my order?

4 How about your payment methods?

5. How do you handle the shipment for my order?and Packing?

6. What is your company warranty policy?

7. Do you offer any replacement for my order?

8. How can I contact to you?

Weifang GUOTE Mine Equipment co.ltd. is professional and modern

enterprise including research and development, engineering design,

production and installation, debugging services , automatic control

equipment, non-metallic mineral production line test, design,

consultation and the complete line of delivery.The scope of

services related to mining, metallurgy, electric power, coal,

glass, paper, chemical building materials, refractory materials,

tiles,food, cement ,etc.Our product sell well in more than thirty

provinces, autonomous region.(For details, please contact me:Annie

Chang,Mob:0086-18678029069(whatsapp),E-mail: Annieflower.chang dot

sdguote.com)

Our product have electromagnetic, permanent magnetic separator, dry

wet magnetic separator,electromagnetic vibration feeder, quartz

sand making machine, air classifier, dust collector, water

separator, washing machine, flotation machine,metal detector, screw

conveyor, timing quantitative feeding,weigher and centralized

control system, etc.

Facing the new opportunities and challenges, the company in line

with the spirit of "honesty-oriented, mutual benefit, cooperation

and innovation" , dedicated to providing “dependable,simple and

efficient” products and services to customers, make enterprises

become domestic advanced mining equipment manufacturer.

Our company is willing to work together with people from all walks

of life for a better future.

We could make whole production line or single equipment following

different clients requirements.

For whole process as below:

Firstly, Please offer detailed technical drawing in CAD or

requirements. Secondly, we will offer different technical proposals

follwing offered drawings or requirements for clients. Thridly make

decision for which proposal.At last manufacture whole equirements

following techncial proposal and holding test in warehouse. Finally

finished equipment/prodcution line offered as turn-key project.

For details, please contact :

Annie Chang ,Mob: +8618678029069(WhatsApp/wechat)

Skype:anna1983cyj ,QQ:896247401

Email:annieflower.chang at sdguote.com

website: https://sdguote.cnen.alibaba.com/

If you have any questions, pls don't hesitated to contacting me

anytime.