HESLY METAL MESH GROUP LIMITED |

|

|  |  |

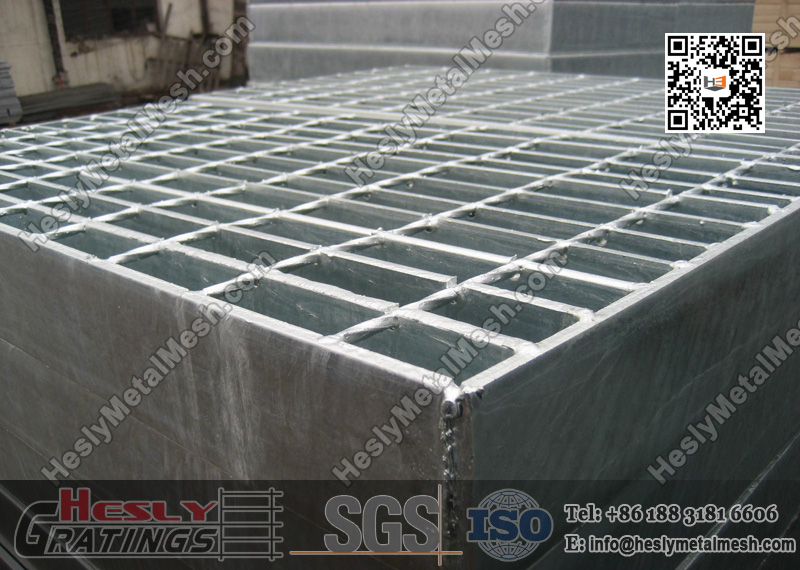

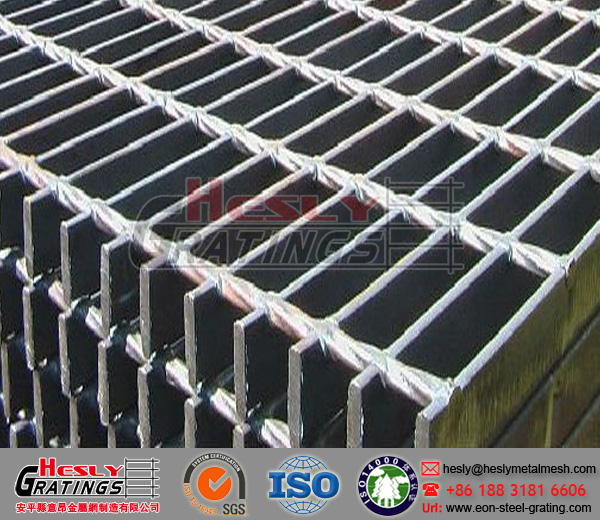

| Heavy Duty Steel Grating | Serrated Heavy Duty Steel Grating | Heavy Duty Steel Grating |

Steel Bar Grating with bearing bars thicker than 3/16" is considered to be "Heavy Duty" and carries the designation prefix "Type HD". Available bar thicknesses are 1/4" (6.4mm) , 5/16" (7.9mm) and 3/8" (9.5mm) in either plain or serrated surface. Standard depths range from 1" (25mm) up to 4" (102mm), although larger sizes are available upon request.

Heavy-Duty Steel Gratings uses thicker <1/4"(6.3mm), 5/16"(8mm), 3/8"(10mm)> and deeper bearing bars. Heavy-Duty Welded Grating has the strength for heavy-duty load areas such as airfields, highways, industrial plants, truck and bus terminals, parking lots and railroad yards. Common uses are flooring, driveways, subway and tunnel ventilation grilles, curb inlet grates, ramps, docks, etc.

Welded Heavy Duty Gratings are designed to service applications subject to heavy rolling and static loads such as highways, plant floors, loading docks, inlet covers and airports. Since these conditions can range from light-duty forklifts to heavy-duty truck or aircraft traffic, heavy duty gratings are manufactured in a wide range of bar sizes and spacings.

| Grating Standard | Material Standard | HDG standard |

China: YB/T 4001.1-2007 | China: GB 700-88 | CHINA: GB/T13912-2002 |

Heavy duty gratings are manufactured in carbon steel and 300 series stainless steels. Carbon steel products are available bare (no finish), painted with manufacturers standard paint, or hot dip galvanized. Stainless steel products are available mill finish, commercially cleaned or electro-polished.

| This is our project of steel grating ,it can be used to many aspects just like: | ||||

| platform | trestle | trend | fence | equipment walk way |

| pavement | channel over | manhole cover | trash rack | mentance platform |

| foot bridge | scaffold | ladder | storage shelf | marine platform |

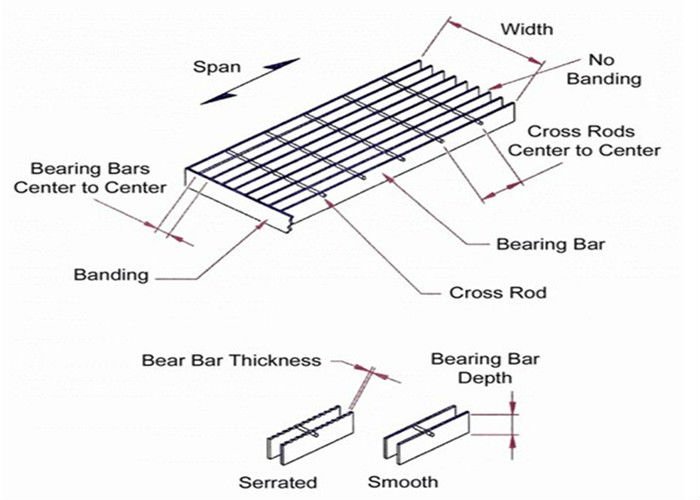

How to order 1.Bearing Bars center to center and cross bars

1.Bearing Bars center to center and cross bars

center to center

2.Depth & thickness of bearing bars

3.Surface:serrated or smooth

4.Dimensions of area

5.Span(direction of bearing bars)

6.Finish: mill,hot dip galvanized

7.banding or no banding

| Contact HESLY for more details or FREE quote... ... | |

| Tel: +86-318-7963989 Mob: +86 188 3181 6606 |

| A branch of HESLY METAL MESH GROUP LIMITED |