Jiangsu LCD Technology Co., Ltd |

|

Technical parameters

| Technical Parameters of Highway Guardrail Roll Forming Machine | ||

| 1 | Material Width | 500-1000mm |

| 2 | Effective Width | 480-680mm |

| 3 | Thickness of Coil | 3-4mm |

| 4 | Application | Highway Guardrail |

| 5 | Estimated Dimension | 15000mmX1800mmX1200mm |

| 6 | Total Weight | 15 Tons |

| 7 | Main Power | 30 KW |

| 8 | Decoiler | Manual or Hydraulic Decoiler |

| 9 | Inner Diameter | 508mm |

| 10 | Outer Diameter | 1200mm |

| 11 | Loading Weight | 15T |

| 12 | Forming Speed | 6—10m/min |

| 13 | Forming Station | 12-15 |

| 14 | Bracket | Welded with 36 # I-steel |

| 15 | Material of Shaft | High Grade 45# Steel with 1st Rough Finished and then 2th Refined Finished |

| 16 | Diameter of the Roll | 100mm |

| 17 | Material of Roller | High Quality CGr15 Quenched HRC58-62 ° |

| 18 | Processing Technology | Rough Processing ---Refined Processing--Hard Chromium Plating. |

| 19 | Material of Rack | Complete Welded Structure of A3 Steel Plate 20 mm Thickness |

| 20 | Transmission | Chain or Gear Box |

| 21 | Material of cutting blade | Cr12 with Quenched Treatment 60-62 ° |

| 22 | Cutting system | Hydraulic Stop or Tracking Cutting |

| 23 | Voltage | 380V/50HZ/3 Phase or as Customer Require |

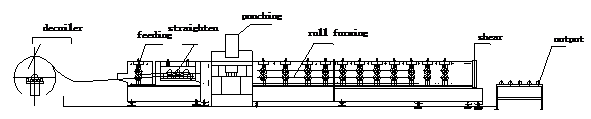

Working flow of the machine

Hydraulic uncoiler—Feeding—Leveling-- hydraulic punching—Roll forming—Hydraulic cutting—output table

Components of the machine

Hydraulic uncoiler------------------------------------------1 set

Leveling------------------------------------------------------1 set

Servo feeding-----------------------------------------------1 set

Hydraulic punching-----------------------------------------1 set

Roll former---------------------------------------------------1 set

Hydraulic cutting--------------------------------------------1 set

Output table-------------------------------------------------1 set

After sale services

1). Engineer will give free training lessons to labors in buyer’s factory.

2). The Buyer will buy the round-trip air ticket for Engineer if visa application is approved. The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance of USD80 for engineer.

3). During this guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by your incorrect operations, we will provide the buyer spare parts at cost price.

We will charge the buyer cost price of spare parts beyond one year and provide long-term technical guide.

Machine pictures