Jiangsu LCD Technology Co., Ltd |

|

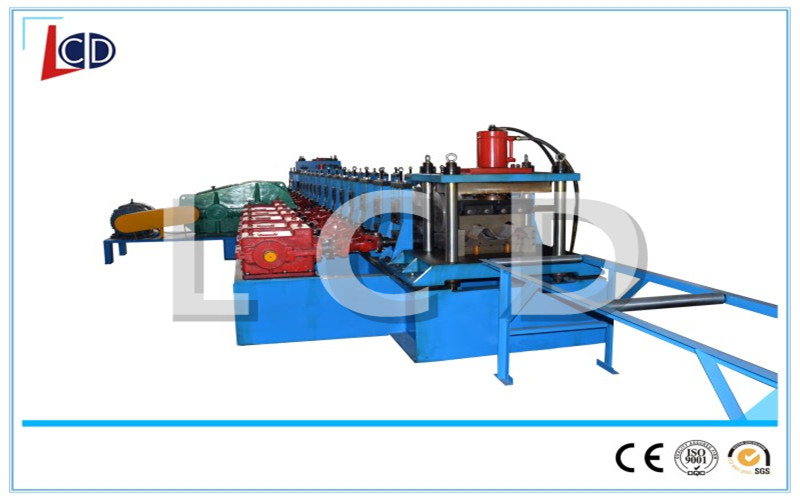

Characters of the machine

1) The structure is very strong and the appearance of the machine is beautiful because we adopt the H beam base with cast iron station for roll forming system

2) All the components of machine are from brand-famous enterprise so that they ensure the machine normal function very effectively.

3) We adopt the automatic length-fixed forming and cutting to guarantee the length to be precise and the finished product clear without deforming .

4) It is very easy to install the equipment and suitable for producing in the factory.

5) Low noise with high efficiency

Components of the machine

Hydraulic uncoiler------------------------------------------1 set

Leveling------------------------------------------------------1 set

Servo feeding-----------------------------------------------1 set

Hydraulic punching-----------------------------------------1 set

Roll former---------------------------------------------------1 set

Hydraulic cutting--------------------------------------------1 set

Output table-------------------------------------------------1 set

Introductions of the machine

This two waves guardrail panel roll forming machine is used for producing two waves highway guardrail, which can meet European standard, with 0.1mm length tolerence, which is high accurancy. Normally speed can reach 15 meters per minute, if you want high speed, we can also make it speed up. This is machine is driven by gear box.

Main Specifications

After sale services

1). Engineer will give free training lessons to labors in buyer’s factory.

2). The Buyer will buy the round-trip air ticket for Engineer if visa application is approved. The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance of USD80 for engineer.

3). During this guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by your incorrect operations, we will provide the buyer spare parts at cost price.

We will charge the buyer cost price of spare parts beyond one year and provide long-term technical guide.

Machine pictures