Shenzhen Bwin Precision Tools Co., Ltd. |

|

HRC45 Solid Carbide Corner Radius End Mill 4 Flutes Rounded Corners Milling Cutter

Characteristic:

Description:

Milling parameters:

| HRC45 Carbide End Mill | Tool length | fz&v | |||||

| Short | 1 | ||||||

| Long1 | 0.9 | ||||||

| Overlength | 0.8 | ||||||

| Speciality | 0.6 | ||||||

| Type | Material | Strength N/mm²

Hardness HRC | Cooling | ||||

| Air | Dry cutting | Lubricating fluid | |||||

| P | PI | P1.1 | Non alloy structural steel, free cutting structural steel, carburized steel and quenched and tempered steel | <700 | √ | √ | √ |

| P1.2 | quenched and tempered steel | <1200 | √ | √ | √ | ||

| P2 | P2.1 | Alloyed nitrided steel, carburized steel and quenched and tempered steel | <900 | √ | √ | √ | |

| P2.2 | Tool steel, bearing steel, spring steel and high-speed steel | <1400 | √ | √ | |||

| P3 | P3.1 | Tool steel, bearing steel, spring steel and high-speed steel | <900 | √ | √ | √ | |

| P3.2 | Tool steel, bearing steel, spring steel and high-speed steel | <1500 | √ | √ | |||

| Sloting | |||||||||||

| Vc (m/min) | fz(mm/Tooth) | |||||||||||

| Diameter | ||||||||||||

| 2 | 4 | 6 | 8 | 10 | 12 | 16 | 20 | |||||

| 112 | 0.01 | 0.018 | 0.026 | 0.034 | 0.041 | 0.048 | 0.06 | 0.069 | ||||

| 92 | 0.01 | 0.017 | 0.025 | 0.032 | 0.038 | 0.045 | 0.056 | 0.065 | ||||

| 100 | 0.01 | 0.018 | 0.026 | 0.034 | 0.041 | 0.048 | 0.06 | 0.069 | ||||

| 72 | 0.009 | 0.015 | 0.022 | 0.028 | 0.034 | 0.04 | 0.05 | 0.058 | ||||

| 64 | 0.01 | 0.018 | 0.025 | 0.032 | 0.039 | 0.045 | 0.057 | 0.066 | ||||

| 56 | 0.009 | 0.016 | 0.023 | 0.029 | 0.036 | 0.041 | 0.052 | 0.06 | ||||

| Roughing | |||||||||||

| Vc (m/min) | fz(mm/Tooth) | |||||||||||

| Diameter | ||||||||||||

| 2 | 4 | 6 | 8 | 10 | 12 | 16 | 20 | |||||

| 228 | 0.018 | 0.031 | 0.045 | 0.057 | 0.070 | 0.081 | 0.101 | 0.118 | ||||

| 208 | 0.017 | 0.029 | 0.042 | 0.054 | 0.065 | 0.071 | 0.095 | 0.11 | ||||

| 184 | 0.018 | 0.031 | 0.045 | 0.057 | 0.070 | 0.081 | 0.101 | 0.118 | ||||

| 144 | 0.015 | 0.026 | 0.037 | 0.048 | 0.058 | 0.068 | 0.085 | 0.098 | ||||

| 132 | 0.017 | 0.03 | 0.042 | 0.054 | 0.066 | 0.077 | 0.096 | 0.112 | ||||

| 112 | 0.015 | 0.027 | 0.039 | 0.05 | 0.060 | 0.07 | 0.088 | 0.102 | ||||

| Finish | ||||||||||

| Vc m/min | fz(mm/Tooth) | ||||||||||

| Diameter | |||||||||||

| 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | ||

| 332 | 0.028 | 0.05 | 0.07 | 0.091 | 0.11 | 0.128 | 0.144 | 0.16 | 0.173 | 0.186 | |

| 272 | 0.026 | 0.046 | 0.066 | 0.085 | 0.103 | 0.12 | 0.135 | 0.15 | 0.162 | 0.173 | |

| 304 | 0.028 | 0.05 | 0.07 | 0.091 | 0.11 | 0.128 | 0.144 | 0.16 | 0.173 | 0.186 | |

| 212 | 0.023 | 0.041 | 0.059 | 0.076 | 0.092 | 0.107 | 0.121 | 0.134 | 0.145 | 0.155 | |

| 196 | 0.027 | 0.047 | 0.067 | 0.086 | 0.104 | 0.122 | 0.137 | 0.152 | 0.165 | 0.177 | |

| 168 | 0.024 | 0.043 | 0.061 | 0.079 | 0.095 | 0.111 | 0.125 | 0.139 | 0.150 | 0.161 | |

| Specification | Flute Dia(D) | R angle | Flute Length (C) | Shank Dia(D) | Overall Length(L) |

| Φ3R0.5*8*d3*50L | 3 | 0.5 | 8 | 3 | 50 |

| Φ3R1.0*8*d3*50L | 3 | 1.0 | 8 | 3 | 50 |

| Φ2R0.5*5*d4*50L | 2 | 0.5 | 5 | 2 | 50 |

| Φ3R0.5*8*d4*50L | 3 | 0.5 | 8 | 3 | 50 |

| Φ4R0.5*10*d4*50L | 4 | 0.5 | 10 | 4 | 50 |

| Φ3R1.0*8*d4*50L | 3 | 1.0 | 8 | 3 | 50 |

| Φ4R1.0*10*d4*50L | 4 | 1.0 | 10 | 4 | 50 |

| Φ5R0.5*13*d5*50L | 5 | 0.5 | 13 | 5 | 50 |

| Φ5R1.0*25*d5*100L | 5 | 1.0 | 25 | 5 | 100 |

| Φ6R0.5*15*d6*50L | 6 | 0.5 | 15 | 6 | 50 |

| Φ8R0.5*20*d8*60L | 8 | 0.5 | 20 | 8 | 60 |

| Φ8R1.0*28*d8*75L | 8 | 1.0 | 28 | 8 | 75 |

| Φ8R2.0*20*d8*60L | 8 | 2.0 | 20 | 8 | 60 |

| Φ8R3.0*20*d8*60L | 8 | 3.0 | 20 | 8 | 60 |

| Φ10R0.5*25*d10*75L | 10 | 0.5 | 25 | 10 | 75 |

| Φ10R1.0*25*d10*75L | 10 | 1.0 | 25 | 10 | 75 |

| Φ10R1.5*25*d10*75L | 10 | 1.5 | 25 | 10 | 75 |

| Φ10R2.0*25*d10*75L | 10 | 2.0 | 25 | 10 | 75 |

| Φ10R3.0*25*d10*75L | 10 | 3.0 | 25 | 10 | 75 |

Instructions:

1. Before using the carbide corner radius end mill, please measure the tool deflection. If the tool deflection accuracy exceeds 0.01mm, please correct it before cutting.

2. The shorter the carbide e extends out of the collet, the better. If the tool extends out longer, reduce the speed, feed speed or cutting amount.

3. In case of abnormal vibration or sound during cutting, please reduce the speed and cutting amount until the situation is improved.

4. Spray type and air jet type are preferred for steel cooling, which can improve the use effect of carbide end mill.

5. Note: Not suitable for low speed machines such as rotary table and electric hand drill.

Applications:

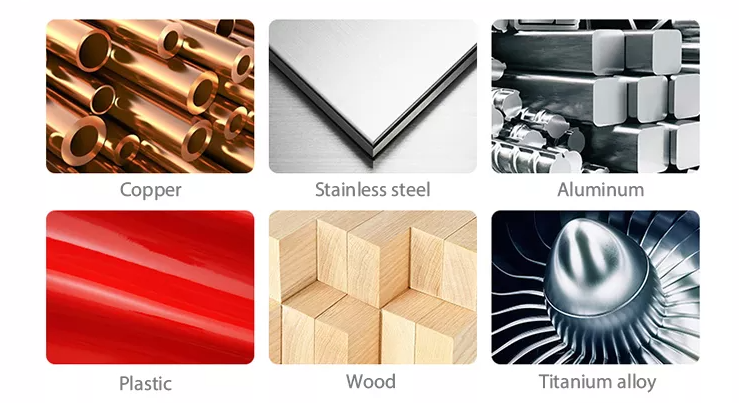

Pre-hardened Steel, stainless steel, Die steel, steel plate, Heat-resistant steel,pipe, copper and aluminum, cast iron, Nonferrous Metal, Wood, Plastic,FRP and sO on. General-purpose operation slotting, rilling, profiling.

Q1. The tool breaks when cutting in or pulling out the workpiece

The feed rate and cutting depth can be reduced, and the cutting edge length can be shortened to the minimum of the necessary length.

Q2. Tool breaks during normal machining

Reduce the feed rate and cutting depth.

The tool shall be passivated.

Replace the clamp or spring collet.

The tool with high cutting edge number changes the tool with low cutting edge number to improve chip removal and prevent chip blockage.

Replace dry milling with wet milling (using cutting fluid), and use it with vortex tube gun to reduce tool temperature and avoid tool overheating.

If the wet milling fluid supply direction is changed from the front to the oblique rear or transverse top, the coolant flow should be sufficient.

Q3. The tool breaks when the feed direction changes

(1) Use arc interpolation (NC machine tool), or temporarily stop (temporarily) feeding.

(2) Reduce (decrease) the feed before and after the direction change.

(3) Replace the clamp or spring collet.

Q4. Problem: Part of the blade tip breaks

Chamfer the corners with manual grinding.

Change down milling to up milling.