Shenzhen Bwin Precision Tools Co., Ltd. |

|

Quick Detail:

Description:

Specifications:

| Brand | BWIN |

| Model | 16ER/16IR 14NPT |

| Color | Black/Yellow |

| Workpiece | Cast iron/Stainless steel/Steel |

| Type | Metal CNC Carbide Lathe Turning Tool |

| Material | Tungsten Carbide Threading Inserts |

| Processing Type | Medium Cutting |

| Feature | Good thermal hardness |

| Excellent wear resistance | |

| Low coefficient of thermal expansion | |

| Good thermal conductivity | |

| Smooth chip breaking | |

| Standard | ISO |

| Quantity | 10pcs/box |

| Weight | 0.015kg |

| Package | Plastic Box |

| Customized Support | OEM, ODM |

Lead Time:

| antity(pieces) | 1 - 3000 | >3000 |

| Lead time (days) | 7 | To be negotiated |

Notice:

Applications:

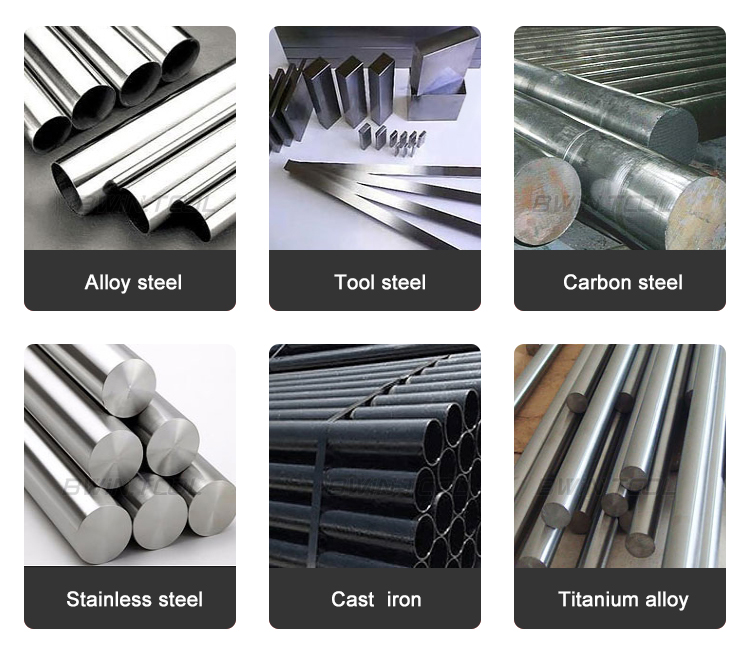

Our carbide threading insert could to be processed Alloy steel, Tool steel, carbon steel, stainless steel, Cast iron and Titanium alloy. Working material as following:

Advantages:

1. Honest merchants, reasonable price and quality assurance

2. Large inventory, sufficient supply and high cost performance

3. Customer service responds in time and delivers goods quickly

4. Provide after-sale guarantee to make your after-sale service free

1. Rear cutter face wear: (This is a common practical form)

Influence: the workpiece size gradually changes or the surface light intensity decreases

Cause: The linear speed is too high, reaching the service life of the tool

Measures: Adjust the processing parameters, such as reducing the linear speed and using a blade with higher wear resistance

2. Blade breakage: (bad actual effect form)

Effect: sudden change of workpiece size or surface smoothness, resulting in burrs on the spark surface

Cause: Improper parameter setting, improper tool face material selection, poor workpiece rigidity, unstable blade clamping Measures: check whether the parameter setting is reasonable, and select the corresponding tool according to the workpiece material

3. Serious fracture: (very bad actual effect form)

Effect: sudden and unexpected occurrence, resulting in scrapping of tool handle materials or defective and scrapped workpieces

Cause: The processing parameters are set incorrectly, and the vibrating tool workpiece or blade is not installed in place

Measures: set reasonable parameters, reduce the feed rate and chip, select the corresponding processing blade, and strengthen the rigidity of the workpiece and blade

4. Chips:

Effect: the size of the workpiece is inconsistent, the surface finish is poor, and the workpiece surface is attached with fluff or burrs. Cause: the cutting speed is too low, the feed is too low, and the blade is not sharp enough

Measures: improve the cutting speed, and use blades with higher sharpness for feed rate