WANGDA Machinery Factory |

|

Electric Motor Automatic Setting Brick Machine With Exclusive Wheel Gear

Production Introduce

Electric Motor Automatic Setting Brick Machine with exclusive wheel gear,New design automatic brick setting system cost of hydroform slab making machine 4-20 with great price produces all types of ecological blocks: hollow, solid, paving blocks and curbstones etc.

The machine adopts hydraulic power, strong and stable pressure make bricks compactness and high strength. Automatic feeding box, automatic feeder, automatic material scraping, automatic demolding, production efficiency has been improved greatly. We can produce various types of clay bricks,lego blocks,soil block etc by changing moulds.

Technical Parameters

| Condition | New |

| Type | Hollow Block Making Machine |

| Brick Raw Material | Clay |

| Processing | Brick Production Line |

| Method | Hydraulic Pressure |

| Automatic | Yes |

| Capacity | 30.000.000 pcs/year |

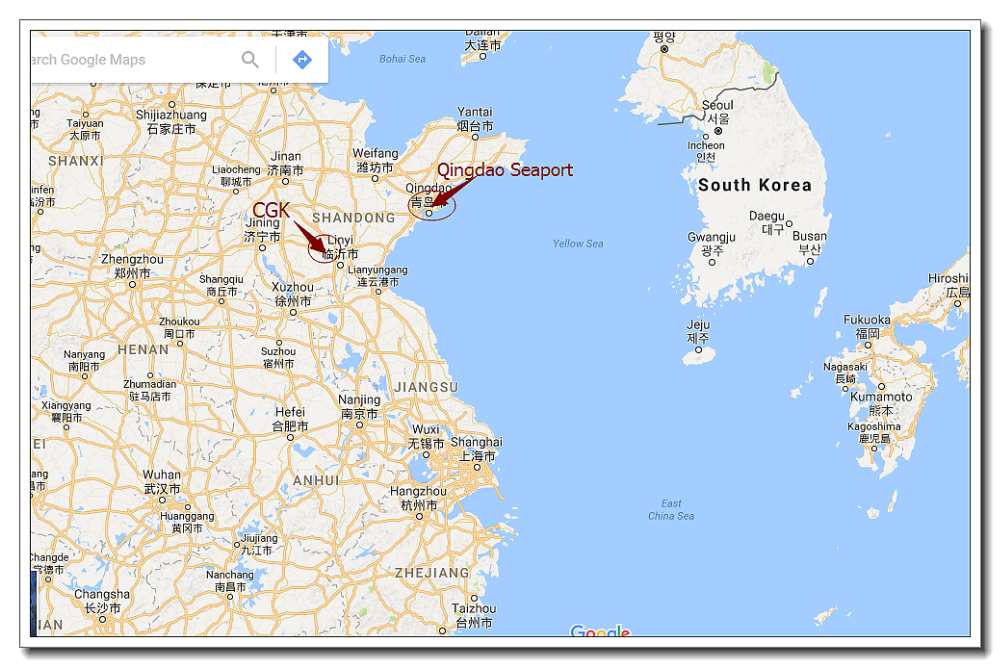

| Place of Origin | Henan, China (Mainland) |

| Brand Name | WANGDA |

| Model Number | ZMP |

| Voltage | 380V |

| Power | 26.6kw |

| Dimension(L*W*H) | as you need |

| Certification | ISO9001-2008 |

| Warranty | one year |

| After-sales Service Provided | Engineers available to service machinery overseas |

| Color | As you need |

| Production | 30-120 million pcs/year |

| Quality | Reliable |

| Performance | Perfect |

| Technology | Advanced |

| Work range | Brick factory |

| After-sale service | Lifetime |

| Exported | Over 15 countries |

| Body of machine | 65Mn steel |

| Factory | Professional Manufacturer |

Specifications | |

Dimension | 2800*2000*3000mm |

Weight | 4000Kg |

Power/Source | 25.7Kw |

Rated Voltage | 220/380 Or as Customer Required |

Moulding Method | Hydraulic Pressing |

Hydraulic Pressure | 21Mpa |

Moulding Cycle | 20s |

Raw Material | Crushed stone, sand, cement, dust and coal fly ash, cinder,

slag,gangue, gravel, perlite, and other construction wastes. |

Productivity | 5760 Pcs/Shift(390*190*190mm) |

Warranty | One Year/Engineer Overseas Available |

Size(L*W*h)mm | Pcs/Molding | Pcs/Hour | Pcs/Shift(8 Hours) |

390*190*190 | 4 | 720 | 5760 |

400*150*200 | 6 | 1080 | 8640 |

390*90*190 | 9 | 1620 | 12960 |

390*240*190 | 3 | 540 | 4320 |

240*115*53 | 28 | 5040 | 40320 |

230*115*75 | 24 | 4320 | 34560 |

200*100*60 | 16 | 2880 | 23040 |

225-112.5*60 | 14 | 2520 | 20160 |

200*160*60 | 12 | 2160 | 17280 |

250*250*60 | 6 | 1080 | 8640 |

Specifications

1. saving 30% energy

2. easy maintenance

3. popular in oversea market

4. stable operation

5. professional training

The workflow of hydraullic brick setting machine:

a When the cutter pushes the green bricks to the separating board , the separator starts work , it drives the separating board stretch and separate the bricks .

bWhen the brick separating is finished , the lift cylinder turns down .

c When the clamp plate reaches the pre-set location , the clamp plate fixture picks up the bricks ,and then it is lifted to a predetermined height by the lifting cylinder .

After all those progress , the separator opens the air duct and the moving evice drives brick stacking machine to the top of the kiln car , the kiln car rotates 90° and then lift cylinder drops down to a predetermined height for setting bricks , the clamp plate opens and lays the bricks on the kiln car , it completes stacking stacking process automatically .

With the periodical operation the whole stacking work is finished , all the functiongs are centralized controlled automatically.

Product Display

Project Design

Q1: Could this machine make my brick?

A1: We will design suitable moulds according to customers' drawings

or required size of blocks.

Q2 : What is the payment terms?

A2: T/T, 30% deposits for producing,70% balance before delivery;

L/C would be considered if the amount is big;

For small amount, Western Union, MoneyGram, PayPal is available.

Q3: What is the minimum order quantity?

A3: One set.

Q4: What about delivery time?

A4: Normally, deliver within 30days after receiving deposit.

Q5: What's the motor voltage?

A5: It will be customized to fit your local voltage.

Service

Pre-sale

1. Professional suggestions (raw material matching, machine selection, planning the

condition of building factory, feasibility analysis for brick machine producing line).

2. 24 hours on-line service

3. Welcome to our factory any time.

On-Sale

1. Update the production progress in time.

2. Qualified supervision.

3. Sending Finished product photos and videos for client confirmation.

4. Dispatching on time

After-sale

1. The engineer could go to customer's factory for guidance if needed.

2. Operator training.

3. Technology support for the whole using life.

4. Recall Clients regularly, following up product using and getting feedback.

5. 12 months warranty for all customers.

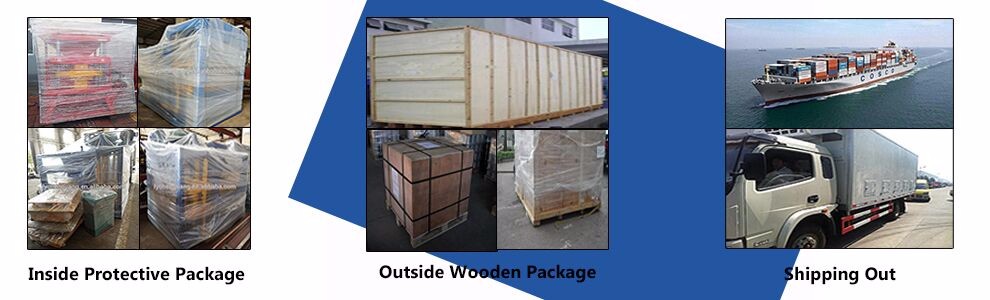

We have our own long time cooperating shipping company, they offer the best freight. And

we would use your shipping company to sent the machines, If you prefer.

The package will be arranged according to client's requirement. Wooden, steel or comtainer,

whichever you prefer.

Certtificate

Company Show

We Offer

1. We provide all kinds of brick making machine.

2. Brick machine accessories: Cement Silo, batching machines,

conveyors, mixers, color feeding system , Stacking machine, moulds,

pallets, Forklift etc the whole production line.

3. Provide PLC Controller, hydraulic station, Electric cabinet, etc

Core technology equipments.

4. Customized block machines as per client requirements.

5. Technical personnel training.

6. According to customer requirements, we can arrange engineer to

customer's factory for installation and commissioning related

services.

7. Provide customers with personalized service, provide solutions

to customer's technical problems.

8. Offer technical support for any block machines client has, even not buying from us.