WANGDA Machinery Factory |

|

Hoffman Kiln Automatic Clay Brick Setting Machine/3 Meters Tunnel Kiln Brick Setting Machine

Production Introduce

Hoffman Kiln Automatic Clay Brick Setting Machine/3 Meters Tunnel Kiln Brick Setting Machine,The setting machine is steady and requires less in space. It’s more flexible in fitting with different kiln types and different output, also more convenience for old factories to reform existing production line.

Technical Parameters

| Condition | New |

| Type | Hollow Block Making Machine |

| Brick Raw Material | Clay, clay, fly ash, coal gangue |

| Processing | Brick Molding Machine |

| Method | Vacuum Extruder |

| Automatic | Yes |

| Capacity | 11000-16000pcs/h |

| Brand Name | Baoshen |

| Model Number | ZMP |

| Voltage | 380V |

| Power | 55+132KW |

| Dimension(L*W*H) | 6750*1880*2540mm |

| Certification | ISO |

| Warranty | 1 year |

| After-sales Service Provided | Engineers available to service machinery overseas |

| Plasticity index of raw material | 7-15 |

| Loss on ignition(%) | 3-15 |

| Drying linear shrinkage rate(%) | 3-8 |

| Coefficient of drying sensitivity | <2 |

| Moisture water content(%) | 16-19 |

| Body of extruder | steel |

Features

Auto green brick setting system is mainly suitable for bricks stacking in the once or twice firing tunnel kiln. The machine adopts the dvanced PLC central control. Frequency conversion controls the rotating, hydraulic controls the lifting-falling clamps, and digital technique controls the brick separating. With the advantage of energy saving, efficiency maintence, low cost and stable operation, it keeps the developed standard in the front rank internationally.

The full-automatic brick setting machine(ZMP)mainly applies to brickstacking in the once or twice firing tunnel kiln. It is controlled by the electricity and hydraulic lift, it has the characters of energy saving, efficiency,easy maintenance, low cost and stable operation.The full-automatic brick setting machine is formed by moving trestle, clamp plate, separator, lifting guide pillar, rail, hydraulic system and electrical system, etc.

The workflow of hydraulic brick setting machine: when the cutter pushes the green bricks to the separating board, the separator starts work, it drives the separating board stretch and separate the bricks. When the brick separating is finished, the lift cylinder turns down. When the clamp plate reaches the pre-set location, the clamp plate fixture picks up the bricks, and then it is lifted to a predetermined height by the lifting cylinder. After all those progress,the separator opens the air duct and the moving device drives brick stacking machine to the top of the kiln car,the kiln car rotates 90oand then lift cylinder drops down to a predetermined height for setting bricks, the clamp plate opens and lays the bricks on the kiln car, itcompletes stacking process automatically. With the periodical operation the whole stacking work is finished, all these functions are centralized controlled automatically.

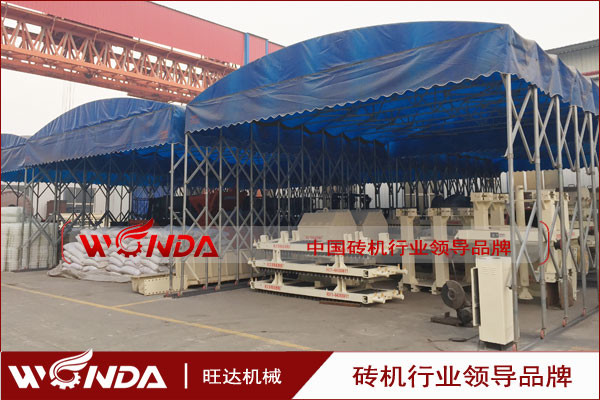

Product Display

Before-sale services:

(1) Tell customer how to build a brick plant, the complete plant including three parts, brick shaping machinery, drying and firing.(Confirm clay,power electricity,water,land area, fund)

(2) Guide customers to choose the best and economic plant, recover the investment within short time.

(3) Site inspection

(4) We are responsible for the offer, flow chart, and detail specification of each machinery.

In-Sale services:

(1) Quality control must be inspected strictly

(2) In accordance with the agreements stipulated in the contract

After-sale services:

(1) We will send the technicians to guide with device installation, debugging and training operators until customers are fully satisfied.

(2) Guarantee for machinery, materials and equipment supplied under this quotation are valid for a period of 12 months after commissioning or 16 months after delivery whichever is earlier. Warranty shall cover manufacturing defect in material and workmanship but exclude:1. Daily wear and tear

2.mishandling or improper operation3. Incoming power supply fluctuation 4. Consumable and spare parts.

(3) Regular visit customer, consult with the customer feedback, come true with the customer's two-way communication.

FAQ

1. what's the raw material for producing bricks?

Answer: clay,mud,gangue,shale etc.

2. how much land area for building a new brick plant?

Answer: it need above 20,000 square meters,the land area relate with capacity

3. when you need our proposal and quotation,what you have to mention in your inquiry.

Answer:please provide daily capacity,the brick size and you want to build a new brick plant or brick making machingery only. so we can give the proposal and offer accordingly.

4. what's the Trade terms?

Answer: it can be EXW,FOB,CIF,CNF,FCA,CPT, CIP

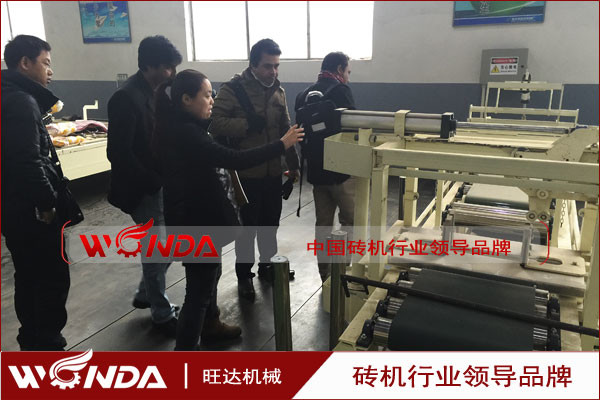

Customer Visit

Workshop $ Factory