Do you know how to choose graphite crucible? 1. Confirming your use, which metal you want to smelting. 2.

Confirming your working temperature and acid-base property. 3.

Confirming your thermal shock property, it is mean the time of your

heating from the 0 degree to the highest temperature. 4. Confirming

your working environment. When you melting, the crucible is in the

air of vacuum.

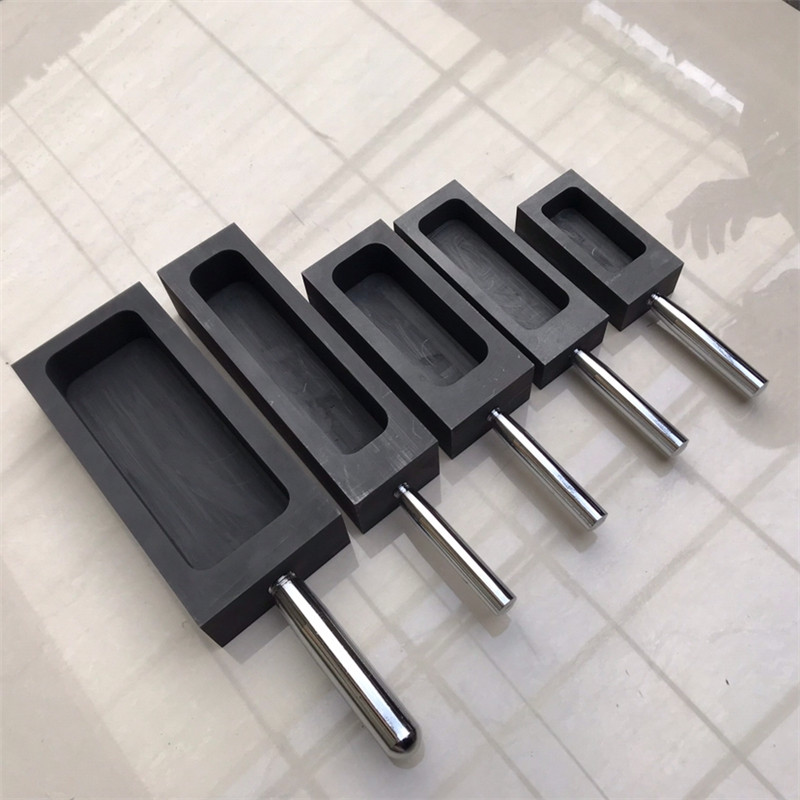

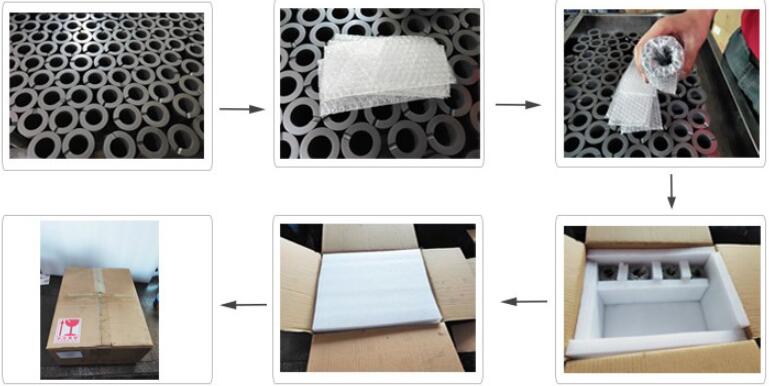

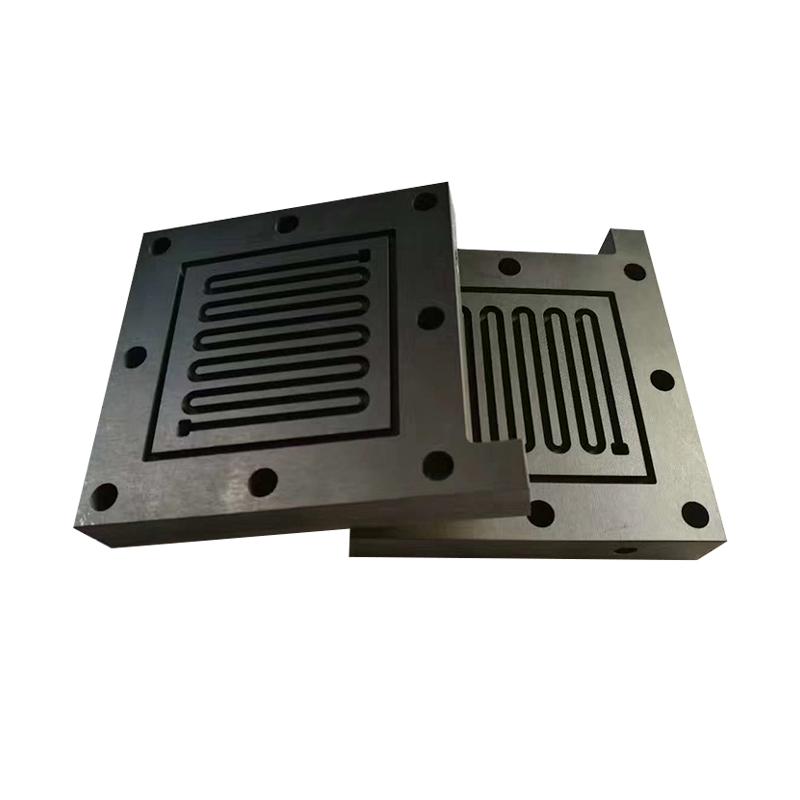

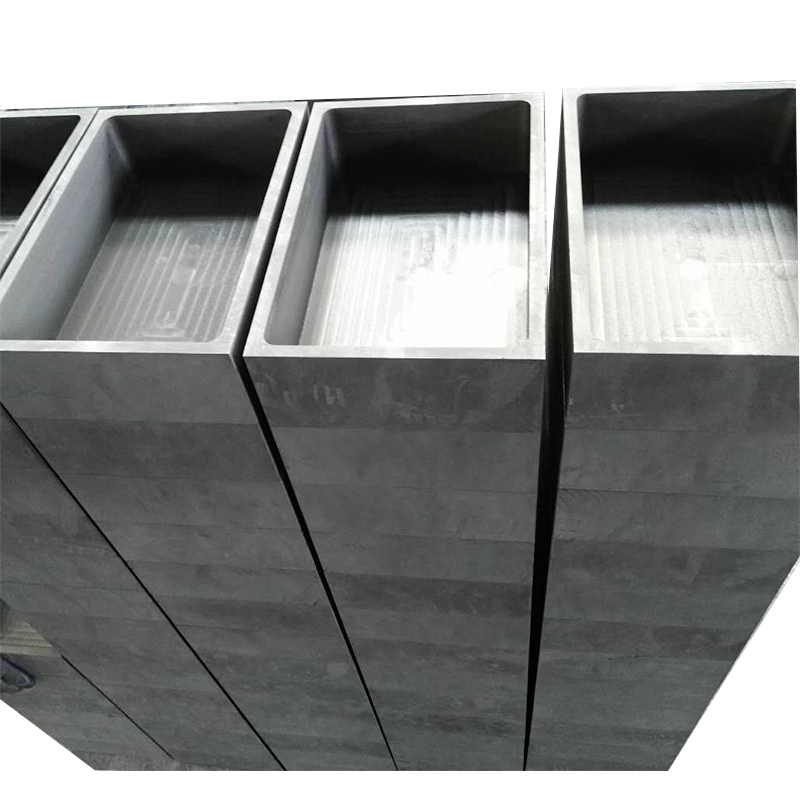

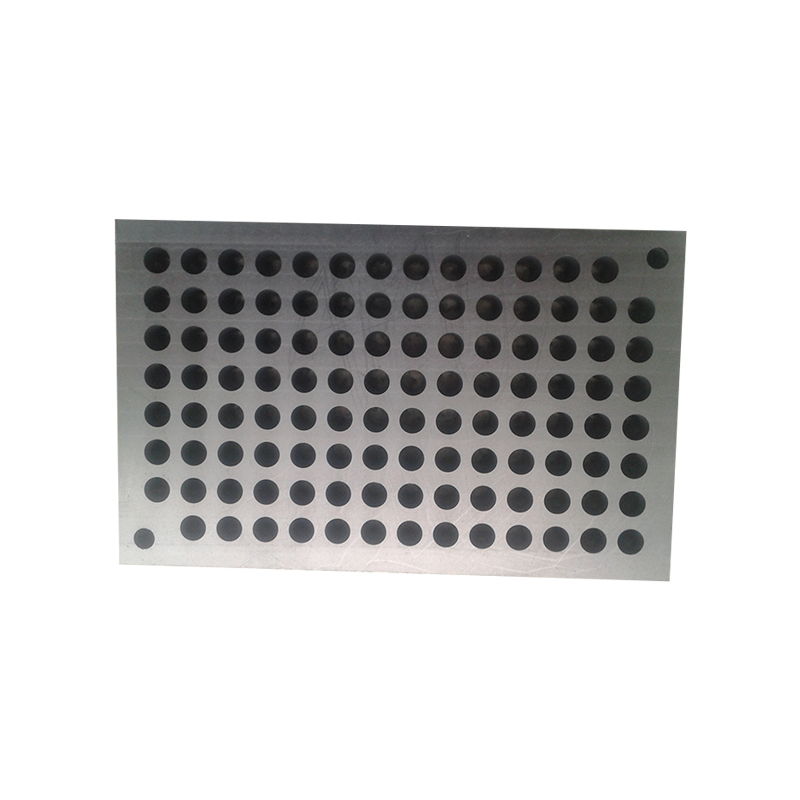

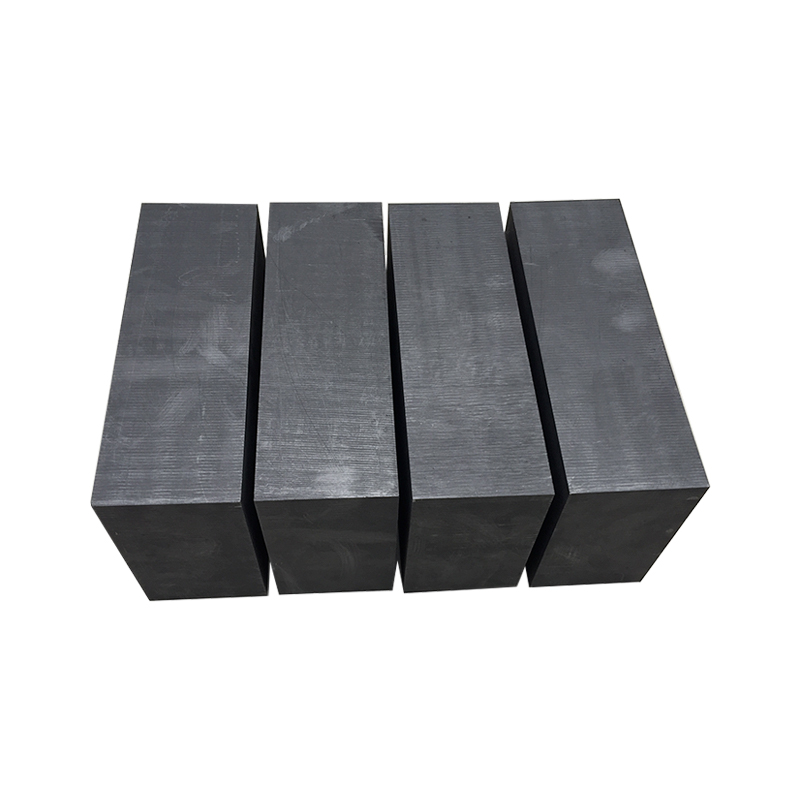

Below are the common using graphite crucibles display(we have them in stock), if you want special shape crucible, just contact us , we can accept customize any shape crucible , ODM OEM is available !!

Just provide the detail size or drawings for us ,we can quote you

!!!