Zhengzhou The Right Time Import And Export Co., Ltd. |

|

MDF Plywood Woodworking CNC Machine Computer Panel Saw Wood Saw Machines OEM ODM

Features:

1. Automatically detect the sawing length of the board,

automatically adjust the sawing time according to the

specifications of the cutting board, shorten the running cycle of

the machine, and improve the work efficiency;

2. Import processing orders into the system to automatically

generate cutting requirements (multiple orders can also be imported

for mixed production), and automatically generate cutting

documents;

3. The board cutting optimization software automatically optimizes

the size of the cutting board, automatically generates a cutting

diagram, improves the utilization rate of the board, and

automatically imports the optimized data into the cutting saw

control system;

4. Automatically feed the board, automatically locate the cutting

size according to the cutting requirements, automatically push out

the board after cutting one piece and locate the next board size to

be cut, continuous cutting, and automatically print barcodes for

each cut board Labels, one plate and one label identification, not

easy to make mistakes;

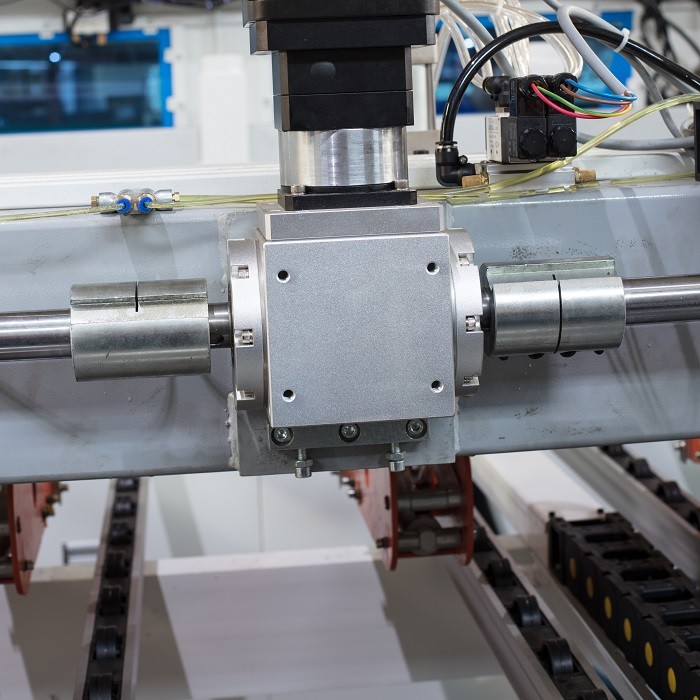

5. The feeding is equipped with imported CST planetary reducer and

grinding-grade rack and pinion to perform accurate positioning, no

need to use magnetic scale for secondary compensation, and the

accuracy is directly guaranteed by mechanical hardware;

6. The saw machine runs smoothly on the linear precision guide

rail, and automatically moves forward and backward for cutting. The

guide rail is installed close to the "U" shape of the body, and the

straightness is excellent without adjusting the machine. .

7. The thickness of the steel plate on the table top of the whole

machine is 25mm thick, and the body weight is 6 tons. It has been

annealed at high temperature by a large heat treatment equipment,

which is solid and durable, and then finished by a large CNC gantry

milling machine to ensure the quality.

| Name | MDF Plywood Woodworking CNC Machine Computer Panel Saw Wood Saw Machines |

| Model | ZDS-3850 |

| Maximum cutting length | 3850mm |

| Maximum cutting thickness | 120mm |

| Positioning method | Automatic |

| Positioning accuracy | ±0.02mm |

| Cutting accuracy | ±0.15mm |

| Main saw motor power | 18.5kw |

| Main saw blade diameter | 450mm |

| Main saw shaft diameter | 60mm |

| Main saw speed | 3800rpm |

| Saw car servo motor power | 1.5kw |

| Mechanical hand servo motor | 1.5kw |

| Vice saw motor power | 1.5kw |

| Vice saw blade diameter | 180mm |

| Vice saw shaft diameter | 30mm |

| Vice saw speed | 6100rpm |

| Feeding speed | 0~80m/min |

| Cutting speed | 0~80m/min |

| Return speed | 0~120m/min |

| Air pressure | 0.6~0.7mpa |

| Machine tool dimension | 6600*7000mm |

| Net weight | About 6800kg |

| Total power | 28kw |

Product advantages:

1) The speed of calculating the board is fast - just import the

bill of materials, and the number of pieces to be cut can be

automatically calculated according to the cutting size in the bill

of materials;

2) Saving plate --- According to the required size of the

calculation plate, optimize the combination through the calculation

optimization software to improve the utilization rate of the plate;

3) Improve the utilization rate of the board---according to the

different board materials required by customers, first consider the

remaining materials of the same material board;

4) Reduce human errors - the optimized results are directly input

into the machine control system to avoid human input errors;

5) Reduce human error---the machine reminds workers how to put the

board to avoid human input errors;

6) Reduce human error - print barcodes or labels as needed to

facilitate identification in the next process;

7) Reduce human error - complete set of material cutting, complete

set of production, complete set of packaging;

8) Improve production efficiency---workers in the back-end process

carry out edge sealing and drilling work according to the label

information;