Fully Automatic Shuttleless Wire Mesh Weaving Machines for For

40-400 Mesh / Inch

Summary of Fully Automatic Shuttleless Wire Mesh Weaving Machines for For

40-400 Mesh / Inch

The light-duty metal wire net weaving machine is applicable for the

industry of metal wire net weaving, and it can be used to weave

mesh nets, microgroove nets and other nonmetal nets. The products

weaved are widely used in various industries including petroleum,

chemical industry, machinery, and aviation, etc.

Fully Automatic- The Shuttleless Wire Mesh Weaving machine adopts

technique of shuttle less and straightaway weft leading, automatic

warp feeding and winding. Shedding are small and surfaces of woven

screens are smooth. There is not any bright spot, bright trace and

other defects on fine screen. The machine can make light-grade in

the standard of GB/T5330-2003. Such as warp wire feeding , rolling

of mesh, braking and warning system when the wire is broken.

Main features of Fully Automatic Shuttleless Wire Mesh Weaving Machines

- It is highly adaptive to metal wires.

- It has a large range for adjustment and can weave in various

patterns including plain weave, tilted weave, bead pattern, and

tapered contrast microgroove.

- The weft wire is linearly led in without any shuttle, the warp line

feeding and take-up are carried out mechanically and automatically,

the opening size is small, and the net surface is flat and orderly

without any defects.

- It works automatic stopping and displaying functions at any warp

broken or weft broken.

- The whole machine works stably in a low center of gravity and a low

level of noise.

Main Parameters of Fully Automatic Shuttleless Wire Mesh Weaving Machines

:

| TYPE | ZWJ-1300B | ZWJ-1600B | ZWJ-2100B |

| MESH SIZE | 40-400mesh/inch | 40-400mesh/inch | 40-400mesh/inch |

| WIRE DIAMETER | 0.025-0.200mm | 0.025-0.200mm | 0.025-0.200mm |

| BEATING-UP FREQUENCY | 70 r/min | 70 r/min | 70 r/min |

| MESH WIDTH | 1300mm | 1600mm | 2100mm |

| MOTOR POWER | 2.2kw | 2.2kw | 2.2kw |

| OVERALL SIZE | 2.6m*2.8m*1.4m | 2.6m*3.1m*1.4m | 2.6m*3.6m*1.4m |

Main components and specification

In the direction of the technical flow for weaving, it mainly

consists of: take-up unit, weft beating-up unit, opening unit, and

warp feeding unit, etc.

Note-The light metal shuttle less wire mesh machine after setting

up can produce Plain Dutch Wire Mesh, Reverse Plain Dutch Wire Mesh

and Twill Dutch Wire Mesh. The Max. Mesh Size can up to 40 To 400

mesh

.

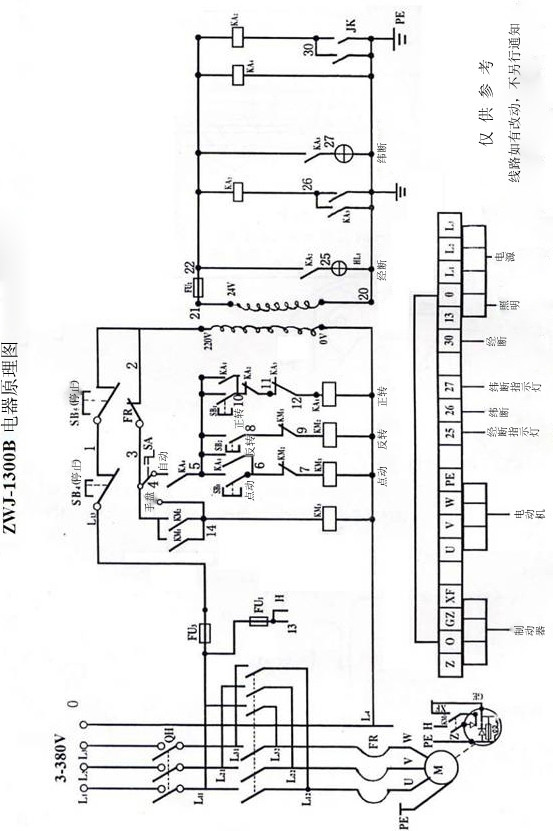

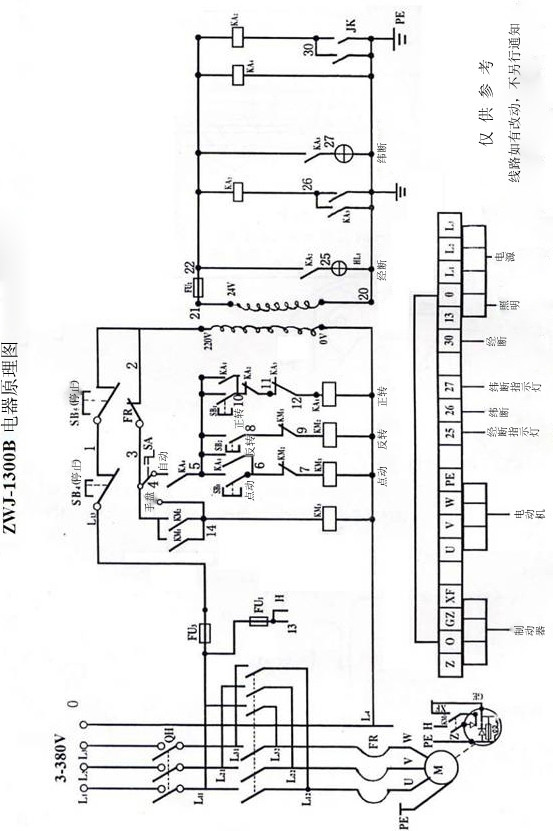

Operation

- The weaving machine can be operated through press buttons and turn

knobs, shown as Fig. 1.

Forward | Inch | Stop | Reverse | Manual | Automatic |

О | О | О | О | О |

- The weaving machine can be started up and stopped at any running

position.

-

- It has the function of automatic stop and red/green light

indication at weft or warp broken.

-

- Turn the knob to the MANUAL stage to release the motor brake for

manual trial running and adjusting.

-

- Turn the knob to the AUTOMATIC stage and then press the FORWARD

button to bring the weaving machine into normal operation.

-

- At a fault of weft broken or warp broken, the weaving machine will

be automatically stopped and the red/green light will give an

indication. The weaving machine can be brought back into normal

operation after the fault is removed, the STOP button is pressed

down, and the indicator is turned off. If the indicator does not

turn off when the STOP button is pressed down, and the weaving

machine can not be brought back into normal operation even by

pressing down the FORWARD button, it means the fault hasn't been

removed yet.

-

- When necessary, the weaving machine can be stopped at any running

position by pressing down the STOP button.

-

- The weaving machine will be brought into reverse running by

pressing down the REVERSE button. Usually reverse running is

required at any weft broken, but it is recommended not using this

function frequently otherwise the rapier will break off the warp

line or the motor will be damaged because of overheat.

-

- The weaving machine will be inching by pressing down the INCH

button, but it is recommended not using this function otherwise the

motor will be damaged.

-

- Installation and Tiral Operation