Hebei Oulite Import&Export Trading Co.,Ltd |

|

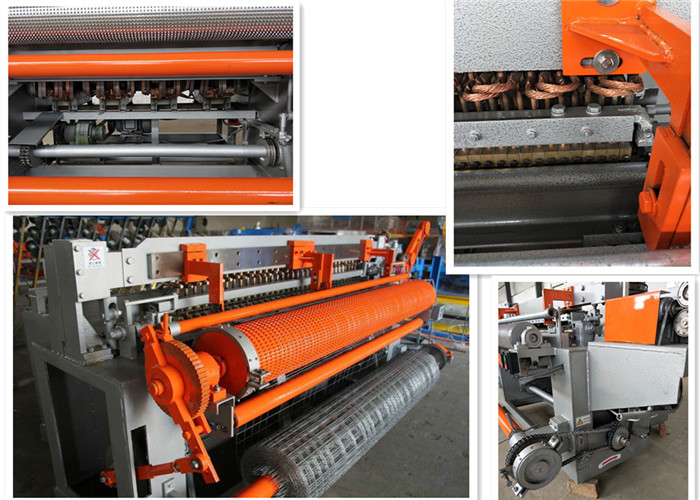

High producing roll mesh welding machine with hole size 10-100mm

Full automatic welded wire mesh machine in roll: the horizontal wire and vertical wire feeding automaticly,mesh coiling automaticly,the machine will stop automaticly when it reaches the setting length.It adpots separate times welding,reduced the load of the power source,making energy efficient.

Machine details:

| Size of mesh (mm) | 12.7-101.6 (1/2"-4") |

| Width (mm) | 914.4-1219.2 ( 12"-48")

|

| Diameter of wire (mm) | Dia.0.63-Dia.2 ( BWG23-BWG14) |

| Max. rolled net size (mm) | 120 (400') |

| Welding speed ( mesh/minute) | 65 ( radia) |

| Power | 380/220V 50-60HZ 50KWAx4 |

| Outside size(mm) |

|

Peculiarity: Big box-style support, high stability, lower noise, E-Machine in one, straighten & send wire automatically. Used for welded wire mesh of big width & wire dia.

Roll fence mesh welded wire emsh machine advantage :

Full automation, welding speed (90 or even 120 times per minute) is almost twice the industry, simple operation, good after-sales service and so on.

Our service:

Guarantee time: 18 months.

Spare parts: If non-quick wear part is broken, we can change for

free.

Installation&training:

Complete installation instructions&circuit diagram.

Send best engineer to your fatory for installation&training.

After-sales:24 hours support service.

Work theory:

The hopper will be running and takes the wire to the positioning device and positioning frame angle place. The upper electrodes press to bottom electrodes , the warp wire and weft wire are welded together. When the upper electrodes raise, stepping mechanism (gear shaft) pull mesh to be the next welded position according to pre-set size . Running back and forth, mesh winding mechanism pull mesh to reel shaft at the same time. It can set the length according to the request of the mesh and shutdown automatically to be pre-set length.

Advantage:

Full automation, welding speed (90 or even 120 times per minute) is almost twice the industry, simple operation, good after-sales service and so on.

Company introduction:

Hebei OLT wire mesh machine company with 55 employees,9000 square meters workshop,more than 30 yesrs experience in metal wire mesh fence.All these help us to be the leading manufacture in Metla wire Mesh and wire mesh mahcinery fied,Dealers from all over country are welcome to visit and purchase .