Hubei Heqiang Machinery Development Limited by Share Ltd |

|

Verified Suppliers

|

|

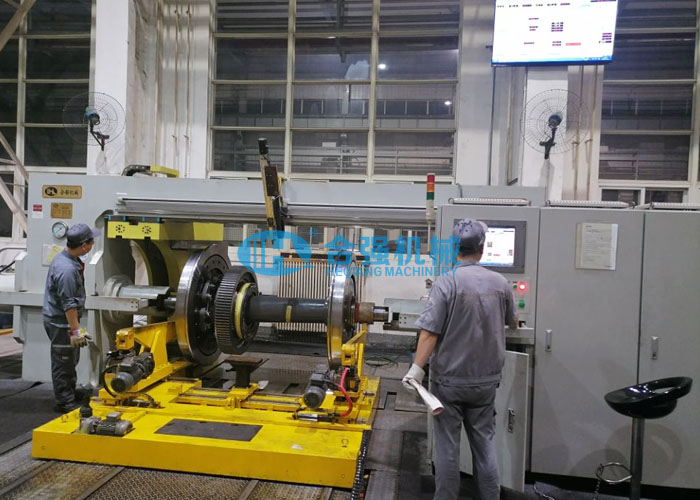

3150kN Double Cylinder Horizontal Wheel Mounting And Dismounting Press

Application scope:

This double cylinder horizontal hydraulic wheel press is a fully automatic design. It's used to mount and dismount the railway wheels and gears safely and effectively for railway rolling stocks. It has two operation mode - Automatic and Manual. It can generate, record, save and print the pressing curves in the required format. Only required one operator to operate the wheel press.

Technical parameters:

| Maximu pressing force | 3150 kN |

| Press ram quantity | 2 pcs |

| Ram cylinder quantity | Double cylinders |

| Maximum cylinder stroke | 800 mm |

| Ram rapid approach speed | 0~25 mm/s, variable |

| Ram pressing speed | 0~4 mm/s, variable |

| Max load of the centring devices | 10000 kg |

| Wheelset support trolley | 1 set |

| Max trolley load | 8000 kg |

Maximum Hydraulic pressure | 31.5 MPa |

| Noise level during working | ≤ 75 dB |

| Main power supply | 3 phase, AC, 380V/50HZ |

| Total installed power | ≤ 30kW |

| Installation space required | Approx. 8000x3500 mm |

| Pressing cycle time | ≤ 12 minutes/axle |

| Pressure sensor accuracy | 0.25% FS |

| Displacement sensor accuracy | 0.01 mm |

| Inner distance control accuracy | ≤ ±0.5 mm |

| Wheel position difference control accuracy | ≤ ±0.3 mm |

| Ram positioning accuracy | ≤ ±0.04 mm |

| Maximum Wheelset weight | 8000 kg |

| Maximum axle length | 2500 mm |

| Maximum wheel diameter | Φ1250 mm |

(*Above parameters are indicative, and can be modified as per customer's actual requirements.)

Machine features:

Overview of Hubei Heqiang:

Hubei Heqiang Machinery is the leading manufacturer of wheel set press machines and Bearing presses in China. Now it covers more than 80% of the China market on Wheelset Presses. We offer the most advanced wheel set pressing equipment available in the railway and other relevant industry. The wheelset presses are used to mount and dismount all of the elements on the axle (wheel discs, brake discs, gears and bearings). With both single and double cylinder version available for option and capacity range from 200 to 800 tons. Our vast range of machines can satisfy all customer requirements in both maintenance and mass production applications.