Guangdong Blue Whale Ultrasonic Equipment Co;Ltd |

|

Verified Suppliers

|

|

Blue Whale Industrial Ultrasonic Cleaner 264L to Remove Rust Grease Oil Dust

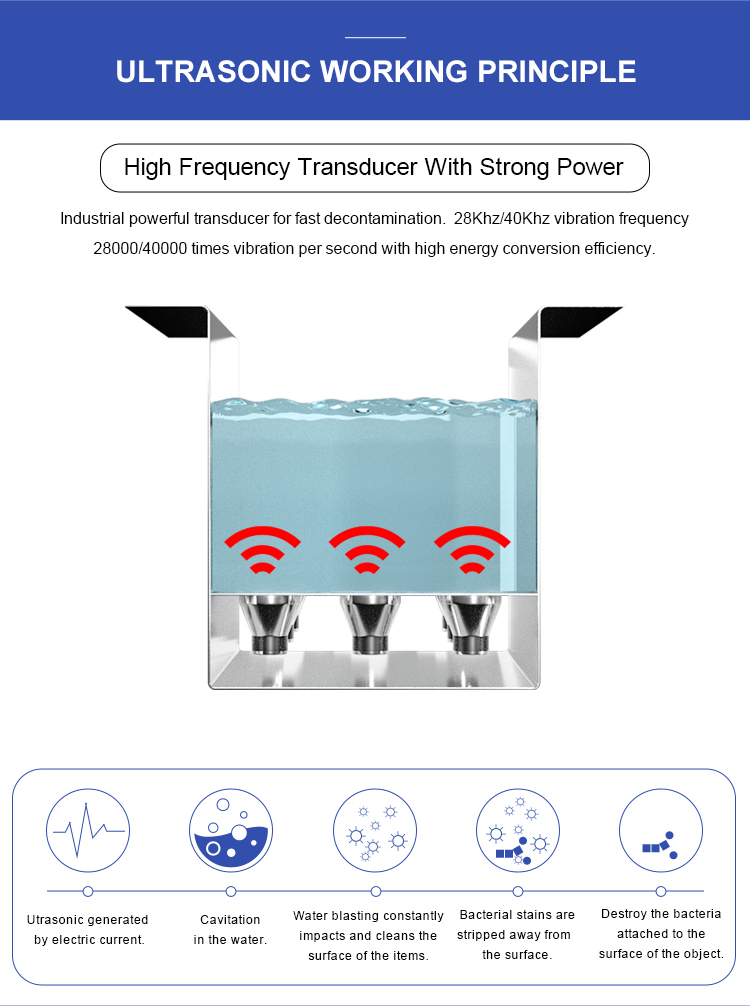

1. What is the working principle of ultrasonic cleaning?

Cavitation is the key mechanism behind the cleaning action in ultrasonic cleaning. When the high-frequency sound waves pass through the cleaning solution, they create alternating pressure waves that cause the formation and collapse of microscopic bubbles. This process generates a tremendous amount of energy, which creates shock waves that dislodge and remove contaminants from the surface of the object.

The bubbles created by ultrasonic cleaning are extremely small and highly energetic, and they can penetrate even the smallest crevices and cavities on the surface of an object. This makes ultrasonic cleaning highly effective at removing contaminants that are difficult or impossible to remove with traditional cleaning methods.

The cleaning solution used in ultrasonic cleaning is also an important factor in the cleaning process. The solution must be carefully chosen to ensure that it is compatible with the object being cleaned and that it can effectively dissolve or disperse the contaminants. The temperature of the solution can also be adjusted to optimize the cleaning process for different types of contaminants.

Ultrasonic cleaning is a highly versatile cleaning method that can be used for a wide range of applications, including cleaning anilox rollers, removing rust and corrosion from metal parts, cleaning medical and dental instruments, and cleaning jewelry and other delicate objects. It is a fast, efficient, and safe cleaning method that can help to improve the performance and lifespan of industrial and commercial equipment.

2. What is the advantages of ultrasonic cleaning?

Increased cleaning efficiency: Ultrasonic cleaning is highly efficient at removing contaminants from surfaces. Because the microscopic bubbles created by ultrasonic cleaning can penetrate even the smallest crevices and cavities, they can effectively remove dirt, grease, oil, and other types of contaminants that may be difficult to remove with traditional cleaning methods. This can result in a more thorough and effective cleaning process.

Reduced cleaning time: Ultrasonic cleaning can significantly reduce the cleaning time required for many applications. Because ultrasonic cleaning is a highly efficient cleaning method, it can reduce the need for manual scrubbing and other time-consuming cleaning methods. This can result in a faster and more efficient cleaning process, which can help to improve productivity and reduce costs.

Reduced labor costs: Ultrasonic cleaning can reduce the amount of labor required for cleaning many types of objects. Because ultrasonic cleaning is a highly efficient cleaning method, it can reduce the need for manual scrubbing and other labor-intensive cleaning methods. This can result in significant cost savings for industrial and commercial applications that require frequent cleaning of multiple objects.

Improved safety: Ultrasonic cleaning is a safe cleaning method that does not require the use of harsh chemicals or solvents, which can be hazardous to workers and the environment. Because ultrasonic cleaning uses sound waves to clean objects, it can help to improve workplace safety by reducing the need for manual scrubbing and handling of contaminated objects. Additionally, ultrasonic cleaning can help to reduce the risk of injury or damage to delicate or sensitive objects.

Improved cleaning quality: Ultrasonic cleaning can improve the quality of cleaning by removing contaminants that may affect the performance or appearance of objects. Because ultrasonic cleaning is a highly efficient cleaning method, it can effectively remove dirt, grease, oil, and other types of contaminants that may be difficult to remove with traditional cleaning methods. This can result in a more thorough and effective cleaning process, which can help to improve the performance, lifespan, and appearance of equipment and components.

Versatile cleaning capabilities: Ultrasonic cleaning can be used for a wide range of applications, including cleaning anilox rollers, removing rust and corrosion from metal parts, cleaning medical and dental instruments, and cleaning jewelry and other delicate objects. This makes it a highly versatile cleaning method that can be used in many industries and applications.

Overall, ultrasonic cleaning offers several advantages over traditional cleaning methods, including increased cleaning efficiency, reduced cleaning time and labor costs, improved safety, improved cleaning quality, versatile cleaning capabilities, and more. These advantages make ultrasonic cleaning a highly effective and efficient cleaning method for many industries and applications.

3. Product Features:

1). Working process: the 1st tank ultrasonic cleaning with heating,

remove the rust, grease and dust from the cleaning items. The 2nd

tank high pressure spraying to provide deep cleaning service. The

alarm buzzes once complete the spraying process.

2). The inner tank material: the use of 304 stainless steel,

thickened to 2mm, manual argon welding, strong and durable;

3). Adjustable time: 1-99 minutes/hour adjustable, can be opened

often;

4). Memory function: the device has an independent memory chip, and

there is no need to reset over and over after the time is set;

5). Equipment power cord: the use of industrial thickened power

cord, safe and durable;

6). Industrial grade transducer: the use of industrial shock head,

strong force and good effect, can work 24 hours uninterrupted;

7). Generator control system: independent generator control system,

flexible control, can be set according to the user's cleaning needs

to adjust the ultrasonic power;

8). Heating automatic constant temperature system: 20-95 degrees

adjustable, equipped with stainless steel heating tube, fast

heating speed.

4. Double Tanks Industrial Ultrasonic Cleaner CHS Series:

Ultrasonic Cleaning, Heating, High Pressure Spraying

5. Customer's Cleaning Feedback:

6. What is the application of ultrasonic cleaning machine?

Industrial cleaning: Ultrasonic cleaning machines are commonly used in industrial settings to clean a wide range of parts and components. These parts can include bearings, gears, valves, nozzles, molds, and many others. Ultrasonic cleaning is highly effective at removing contaminants such as oils, greases, rust, and other debris from these parts before they are assembled or used in manufacturing processes. Ultrasonic cleaning can also be used for precision cleaning of small parts that are difficult to clean using traditional methods.

Medical and dental cleaning: Ultrasonic cleaning machines are used in medical and dental settings to clean a variety of instruments, such as surgical tools, dental instruments, and prosthetic devices. Ultrasonic cleaning is highly effective at removing contaminants such as blood, tissue, and other biological debris from these instruments, which is essential for maintaining a sterile environment. Ultrasonic cleaning machines used in medical and dental settings are often designed to meet specific standards for cleanliness and safety.

Jewelry cleaning: Ultrasonic cleaning machines are commonly used in jewelry stores and workshops to clean jewelry, including rings, necklaces, bracelets, and more. Ultrasonic cleaning is highly effective at removing dirt, grime, and other contaminants from jewelry, restoring their shine and luster. Ultrasonic cleaning machines used for jewelry cleaning are often designed with specific settings and solutions to ensure that delicate and valuable jewelry is not damaged during the cleaning process.

Automotive cleaning: Ultrasonic cleaning machines are used in the automotive industry to clean a variety of engine parts, transmission parts, and other components. Ultrasonic cleaning is highly effective at removing contaminants such as carbon buildup, oil, and grease from these parts, improving their performance and lifespan. Ultrasonic cleaning can also be used for precision cleaning of small automotive parts that are difficult to clean using traditional methods.

Electronics cleaning: Ultrasonic cleaning machines are used in the electronics industry to clean a variety of components, such as circuit boards, connectors, and other electronic parts. Ultrasonic cleaning is highly effective at removing contaminants such as dust, dirt, and other debris from these components, improving their performance and reliability. Ultrasonic cleaning machines used for electronics cleaning are often designed to meet specific standards for cleanliness and safety.

Overall, ultrasonic cleaning machines are highly versatile and can be used in a wide range of applications in various industries and settings. They offer a safe, efficient, and cost-effective method for cleaning a wide range of objects and components, improving their performance and lifespan.