Zhengzhou Sincola Machinery Co., Ltd |

|

Introduction

Dry putty powder production line (or dry filler wall putty mix

plant) is a set of machinery that produces dry putty powder for

construction industry and other uses.

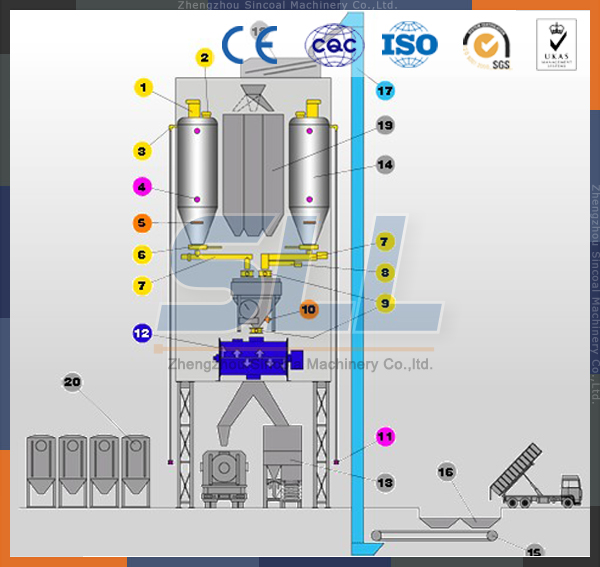

Full Automatic Dry putty powder mix plant mainly produces ordinary

premixed dry putty powder or dry putty powder with special function

for interiro and exterior wall. The whole putty powder production

line includes Mixing machine, Drying system, Screening system,

Measuring system, Bulk and Packing system, Dedusting system,

Electrical system and Spot agitation tank.

Full autoamtic dry mortar plant plaster dry mortar production

line,the pretreatment raw materials will be lifted into raw

material silo, then raw material is flowing through the hopper,

Next, by computer ingredients, screw conveyor metering, mixing and

packaging machine package to bags or in bulk or finished goods

warehouse into the car storage process into the final product.

Feature of Dry mix mortar production line

1. Low speed, high efficiency mixing, gentle movements, double mix

2. Mixing speed, each batch mixing time: 1-3 min, high mixing

evenness

3. Differences in specific gravity, particle size, shape and other

physical properties of the material is not easy to produce

segregation during mixing

4. Large range of liquid added, add up to 20%

5. Practical range, according to user needs to use carbon steel,

stainless steel, stainless steel, especially suitable for high

precision material mixed production requirements.

Application

1. wall putty

2. tile or floor adhesive mortar

3. masonry mortar

4. self-leveling mortar

5. tile or floor grout mortar

6. base-mortar

7. anti-crack mortar

8. water-proof mortar, etc.

Technical Parameters

| Mode | Capacity | Area | Height | Note |

| Simple | 1-5t/h | 40m2 | 3m | Manual batching and packing |

| Basic | 5-15t/h | 40-60m2 | 6-10m | Manual batching ,automatic packing |

| Semi Automatic Serial | 5-15t/h | 40-80m2 | 8-12m | Automatic batching of coarse material,manual batching of additive ,automatic packing |

| Full Automatic | 5-50t/h | 40-100m2 | 10-25m | Automatic batching of coarse material,manual batching of additive,automatic packing |

| Full Automatic Tower | 55~100t/h | 60~500m2 | 10-30m | Automatic batching of coarse material,manual batching of additive,automatic packing |