Shanghai Genius Industrial Co., Ltd |

|

Verified Suppliers

|

|

Robotic welding machine benefits

In the welding process, as long as the welding parameters and the trajectory are given, the robot will repeat this action accurately. The welding parameters such as welding current, voltage, welding speed and welding wire length will determine the welding result. When using robot welding, the welding parameters for each weld are constant. The weld quality is less affected by human factors, which reduces the requirements for the workers' operating technology. Therefore, the welding quality is stable, thus ensuring the quality of our products quality. In the case of manual welding, the welding speed, the elongation of the wire are all changed, so that it is difficult to achieve uniformity of quality.

Robotic welding machine specification

| Robot model | ZK1400-06 | |

| Application | Arc welding | |

| Mounting | Vertical ground installation | |

| Number of axes | 6 | |

| Payload | 6kg | |

| Max working radius | 1400mm | |

| Repeated posiontioning accuracy | 0.03mm | |

| Maximum joint range | J1 | RV reducer ±160° |

| J2 | RV reducer +110°, -70° | |

| J3 | RV reducer +65°, -120° | |

| J4 | RV reducer ±150° | |

| J5 | Hollow harmonic reducer +105°, -110° | |

| J6 | Hollow harmonic reducer ±320° | |

| Maximum joint speed | J1 | RV reducer 201.9°/S |

| J2 | RV reducer 198.3°/S | |

| J3 | RV reducer 198.3°/S | |

| J4 | RV reducer 296.2°/S | |

| J5 | Hollow harmonic reducer 197.5°/S | |

| J6 | Hollow harmonic reducer 247.2°/S | |

| Allowable bending moment N.m | J4 | RV reducer 9.8N.m |

| J5 | RV reducer 9.8N.m | |

| J6 | Hollow harmonic reducer 4N.m | |

| Allowable inertia Kg.㎡ | J4 | RV reducer 0.3kg.㎡ |

| J5 | RV reducer 0.3kg.㎡ | |

| J6 | Hollow harmonic reducer 0.05kg.㎡ | |

| Body total weight | KG | 185KG |

| Operating environment | Temperature | 0℃-45℃ |

| Humidity | 20%-80% | |

| Others | Keep away from corrosive gases or liquids or explosive gases, | |

| Power capacity | 6KVA (Robot) + 24KVA (Welding source) | |

Robotic welding machine control system functions

Integrated drive and control, open control system, comprehensive compatibility.

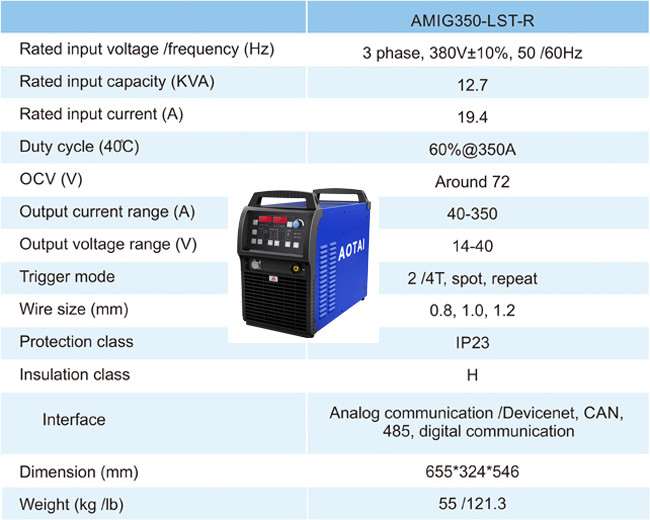

Robotic welding machine power supply introduction

It is fully digital MIG series with new Low Spatter technology. Due to high end DSP + FPGA and waveform control technology. It provides outstanding control of arc and weld pool and bring spatter free welding quality and high efficient productivity.

Robotic welding machine welding effect