Shanghai Genius Industrial Co., Ltd |

|

Verified Suppliers

|

|

Notes for using robotic welding machine

The welding robot includes a robot body, a control cabinet, a

teaching programmer, a welding power source, a wire feeding device,

and a welding gun device.

1. Select the installation location of the welding robot. The

welding robot contains many high - precision components, especially

its control cabinet. Although it is well dust - proof, the poor

environment at the installation site will reduce the life of the

robot.

Therefore, in order to avoid adverse effects on the welding robot

caused by environmental factors and prolong its service life, the

welding robot should be installed in a place that is waterproof,

dry and has little dust. And the control cabinet and welder are

required to keep a distance from the ground.

2. In general, the welding robot has been calibrated to its origin

position before leaving the factory, but even so, the center of

gravity position measurement and tool position check are performed

when the robot is installed. This step is relatively simple, just

need to find the menu in the settings of the welding robot, step by

step, follow the prompts.

3. After the welding robot is installed, it is necessary to take

safety precautions. If someone approaches, it may cause a major

safety accident.

Therefore, as far as possible, install a protective fence on the

outside of the welding robot to prevent unrelated personnel from

approaching; when operating the welding robot, the staff should

also wear protective equipment; the start button is set in the safe

position of the robot to avoid potential safety hazards.

Robotic welding machine specification

| Robot model | ZK1400-06 | |

| Application | Arc welding | |

| Mounting | Vertical ground installation | |

| Number of axes | 6 | |

| Payload | 6kg | |

| Max working radius | 1400mm | |

| Repeated posiontioning accuracy | 0.03mm | |

| Maximum joint range | J1 | RV reducer ±160° |

| J2 | RV reducer +110°, -70° | |

| J3 | RV reducer +65°, -120° | |

| J4 | RV reducer ±150° | |

| J5 | Hollow harmonic reducer +105°, -110° | |

| J6 | Hollow harmonic reducer ±320° | |

| Maximum joint speed | J1 | RV reducer 201.9°/S |

| J2 | RV reducer 198.3°/S | |

| J3 | RV reducer 198.3°/S | |

| J4 | RV reducer 296.2°/S | |

| J5 | Hollow harmonic reducer 197.5°/S | |

| J6 | Hollow harmonic reducer 247.2°/S | |

| Allowable bending moment N.m | J4 | RV reducer 9.8N.m |

| J5 | RV reducer 9.8N.m | |

| J6 | Hollow harmonic reducer 4N.m | |

| Allowable inertia Kg.㎡ | J4 | RV reducer 0.3kg.㎡ |

| J5 | RV reducer 0.3kg.㎡ | |

| J6 | Hollow harmonic reducer 0.05kg.㎡ | |

| Body total weight | KG | 185KG |

| Operating environment | Temperature | 0℃ - 45℃ |

| Humidity | 20% - 80% | |

| Others | Keep away from corrosive gases or liquids or explosive gases, | |

| Power capacity | 6KVA (Robot) + 24KVA (Welding source) | |

Robotic welding machine motion range

Robotic welding machine power supply introduction

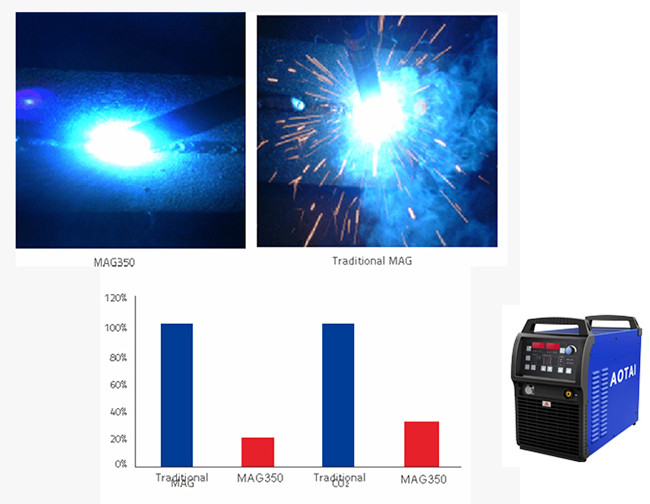

It is fully digital MIG series with new Low Spatter technology. Due to high end DSP + FPGA and waveform control technology. It provides outstanding control of arc and weld pool and bring spatter free welding quality and high efficient productivity.

FAQ

Q: Are you a manufacturer or a trading company?

A: We are a manufacturer, and our factory located in Nantong city,

Jiangsu province. Our company occupies an area of 32,000 square

meters, with a plant area of 25,000 square meters. It has 72 senior

technicians, 42 technicians directly researching and developing, we

are a manufacturer with strong R & D capabilities and own core

technology, sincerely welcome to visit our factory.

Q: Why choose Genius welding robot ?

A:

1. Core components like RV reducer, harmonic reducer and servo

motor independently R & D by ourselves, save cost then have a

better price to customers, besides, ensure the coordination and

consistency of robot, then ensure the quality at last.

2. For servo motor, absolute value encoder, servo motor and RV

reducer direct connect horizontal volume size smaller.

3. For Wire Feeder, 30 years experience, now production No.3 in the

world, we are also supplier of Yaskawa and FANUC for wire feeder.

4. For Robotic arm housing, die casting, smooth surface, metal

color antirust for 10years.

5. For Welding gun, integrated design, reducing resistance of wire

through path, wire feeding smoothly.

6. For Dis - collision device, high sensitivity, after

crash,immerdately work and no need adjustment.

Q: How about your after - sale service?

A:

1. Installation Services: In the period of installation and

debugging, we shall offer training about effective operation and

maintenance.

2. Technical Services: We can assist our clients to solve all kind

of technical problems with our capable technical team, and we own

adequate experience for production line transformation project.

3. Warranty Services: We offer free after sale service except the

engineers' traveling expense for any quality problem occurs during

our 12 months warranty period.

.

Q: What is your payment term?

A: The payment method is 50% prepayment, 50% balance before cargo

delivery if the client does not need onsite installation or

debugging;

The payment method is 50% prepayment, 40% balance before cargo

delivery, 10% upon verification in the client’s factory if the

client needs onsite installation or debugging.

Other optional device - welding positioner table