Anping Tianke wire mesh equipment Co., Ltd |

|

Concrete Wire Mesh Panel In Construction Concrete Mesh Welding Machine

Concrete Mesh Welding Machine Description

Concrete mesh welding machine is a kind of automatic welded wire mesh making machine.The machine adopts CNC control system,is a high degree of automation row welder.This concrete mesh welding machine only needs two workers to operate.The machine can weld all the cross points on the weft wire at one time with high efficiency.So our wire mesh welding machine is popular with our foreign customers.

Concrete Mesh Welding MachineTechnology

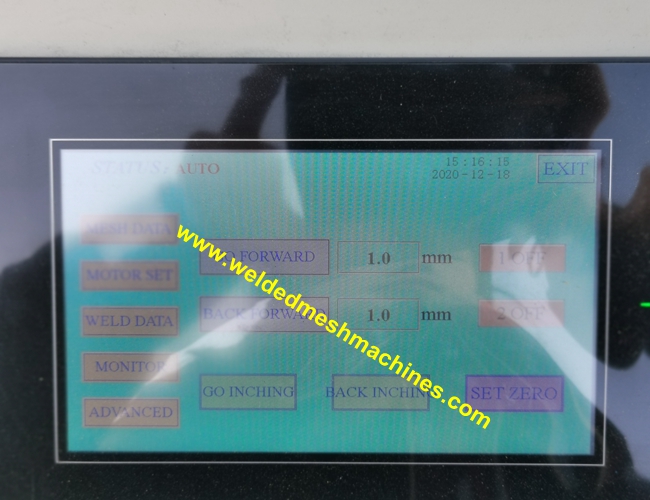

1. The control panel is more intelligent, very easy to operate.

2. The longitude wires should be inserted into slot tunnels (cast

iron material), suitable for different diameter.

3. The cross wires are fed from cross wire feeder, controlled by

step motor and air cylinder.This can ensure the wire feeding more

accurate.

4. The welding electrode is made of high quality chromium copper

with long service life

5. Clutch motor and helical gear reducer connect the principal axis

directly, welding stable.

6. Casting water-cooling welding transformers, high efficiency. The

welding degree is adjusted by PLC.

7. Step motor and reducer are used in mesh panel push device.This

can guarantee the accuracy of the net.

8. The cable drag chain is famous brand which can used for long

time.

Concrete Mesh Welding Machine Feature

1. The machine is used for wire diameter 5-12mm, it is an automatic equipment that desiged and manufactured by ourselves. This machine is driven by pneumatic system and composed of line wire support system, water cooling welding transformer, pneumatic control cross wire falling system, servo motor pulling mesh device.

2. The machine uses Janpan Mistubishi PLC touch screen control technique, we use Japan, Sony digital control system which can be input to touch screen control panel to adjust the mesh size, so it can weld different mesh size between the weft wires

3. Water-cooling transformer and water-cooling lower electrodes to make sure the welding firm during a long working time, and prolong the service life.

4. Feeding and Welding System

A: Weft wire feeding: Firstly, the coil wires are straighten and cut into fixed length by straightening cutting machine, which become weft wire. Then worker put the weft wires into wire hopper. Wire hopper under the control of step motor, the weft wires will fall automatically one by one

B: Warp wire feeding: warp wires are the same to weft wires, firstly use wire straightening and cutting machine to straighten and cut coil wire into fixed length. Then the line wires are sent by labor and fed automatically, when the machine is welding,labors can prepare the warp wires for the next mesh panel in advance, it increases the production efficiency.

5. Welding system: the machine welding system is controled by pneumatic system, which makes the adjusting of welding pressure simple and convenient. At the same time, the welding electrodes are equipped with water cooling system to make sure the welding during a long working time, and prolong the life .

6.The mesh pulling system is controlled by step motor, which makes the pulling mesh aperture more standard

and accurate.

7. Mesh falling system: Automatic falling mesh panel system is adopted, so it save much labor to move the mesh panels.length 12m control by air cylinder .

Concrete Mesh Welding Machine After sales service

1. Guarantee time:one year since machine was at buyer' factory within 18 months against B/L date

2. Within guarantee time, if any components are broken under normal condition, we can change for free.

3. We can send our best technician to buyer's factory for installation, debugging and training.

4. Complete installation instructions, circuit diagram, manual operations and machine layout.

5. Technical support by e-mail.

Concrete Mesh Welding Machine

1. PLC visual touch screen: The machine control system has visual touch screen.The system adopts Chinese and English, which is convenient for the operator to use.

2. Electronic components: All the electronic components we are using is in high quality. After more than ten years of use, the electronic components have good performance, low failure rate and guaranteed quality.

3. Package and Shipping: The main machine is fixed with wire rope to prevent sliding and collision in the container.

4.Finished product